Endoscope

A technology for endoscopes and insertion parts, applied in the field of endoscopes, can solve problems such as inability to perform correct bending, inability to perform, fatigue deformation, etc., and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

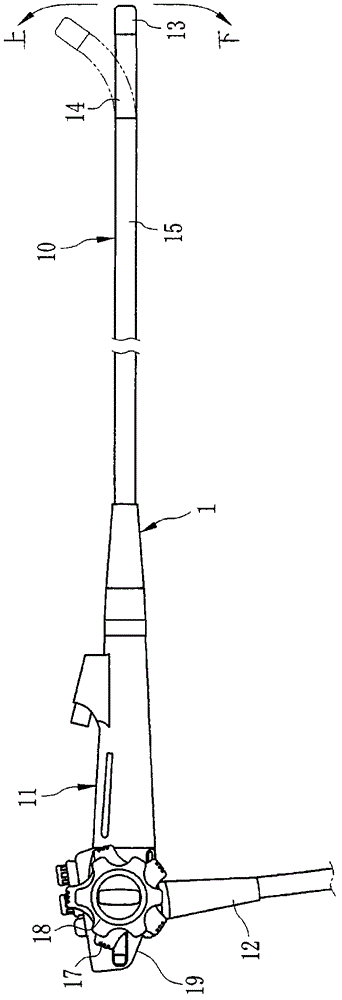

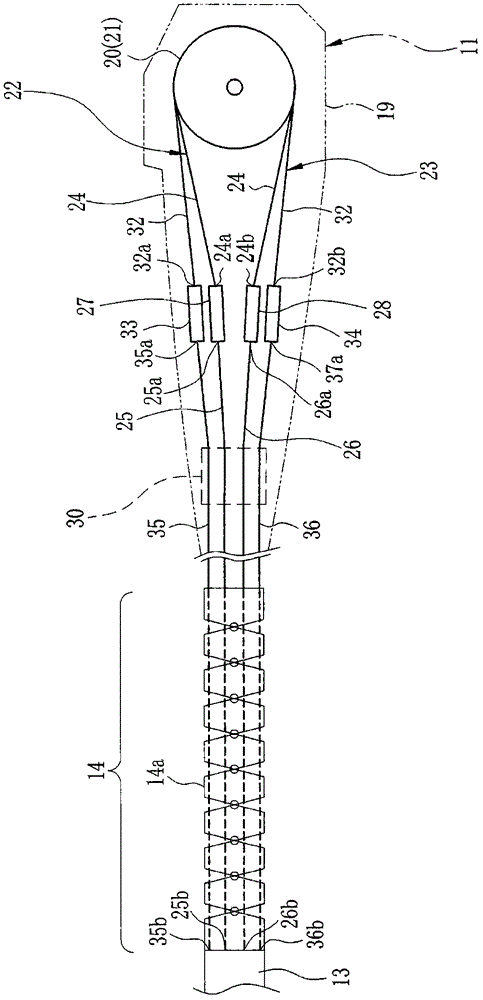

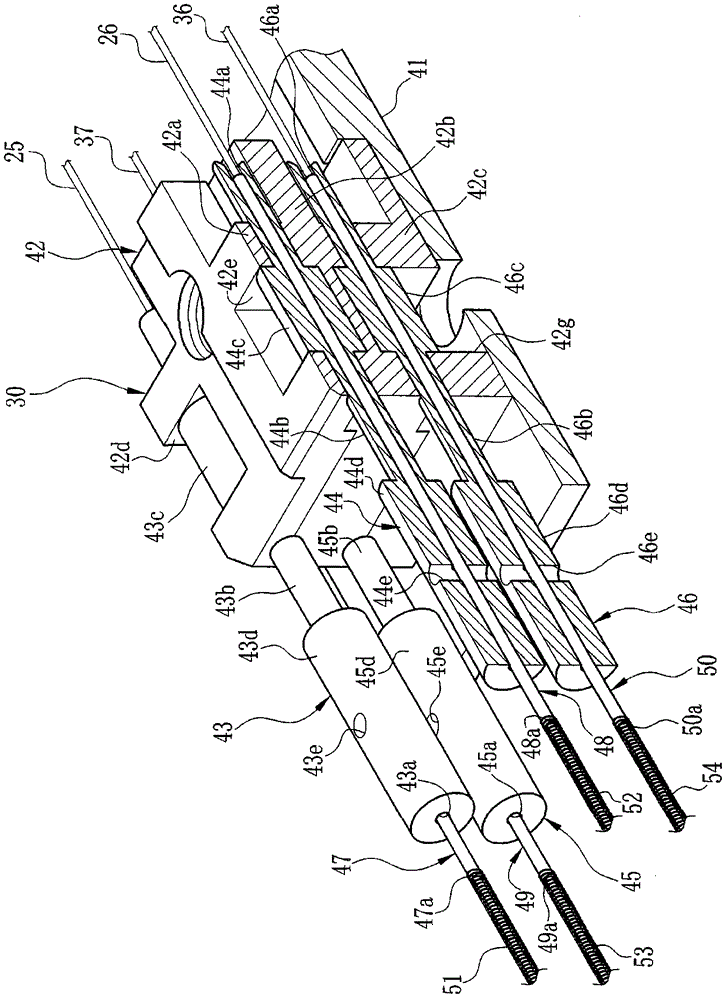

[0015] figure 1 Among them, an electronic endoscope 1 includes an insertion unit 10 inserted into the body, an operation unit 11 for operating the insertion unit 10 , and a universal cord 12 extending from the operation unit 11 . The insertion part 10 has a front end rigid part 13 , a freely bendable bending part 14 and a flexible flexible part 15 . The flexible part 15 has a length of, for example, about 2 m so that the distal rigid part 13 reaches a desired observation site in the body.

[0016] As is well known, the front end rigid portion 13 has built-in imaging elements such as an objective lens, a CCD, and a CMOS image sensor. The image of the observation site in the body is formed on the imaging element through the objective lens. The imaging element converts an optical image into an electrical signal. An imaging signal from the imaging element is sent to the operation unit 11 through a signal cable inside the insertion unit. Then, it is transmitted to a processor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com