Double-side polishing machine

A double-sided polishing machine and polishing head technology, which is applied in the field of polishing machines, can solve problems such as low efficiency, and achieve the effect of reducing costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

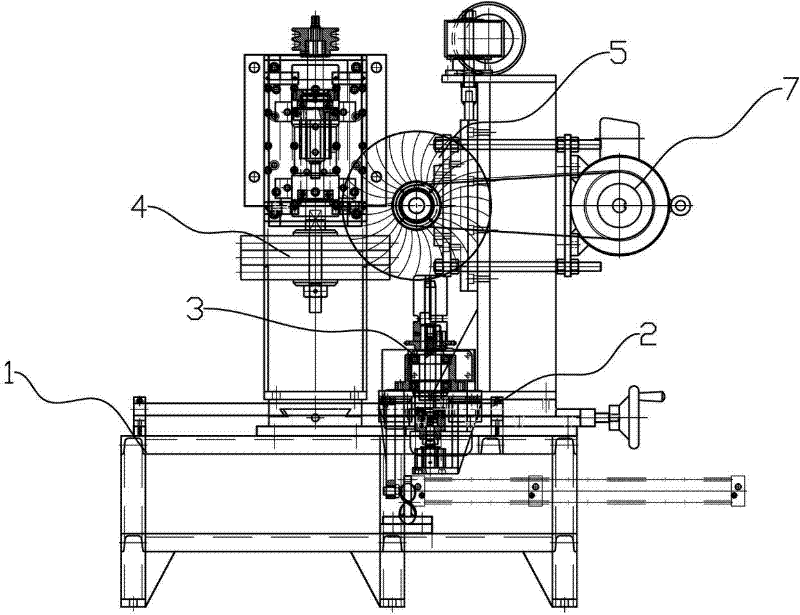

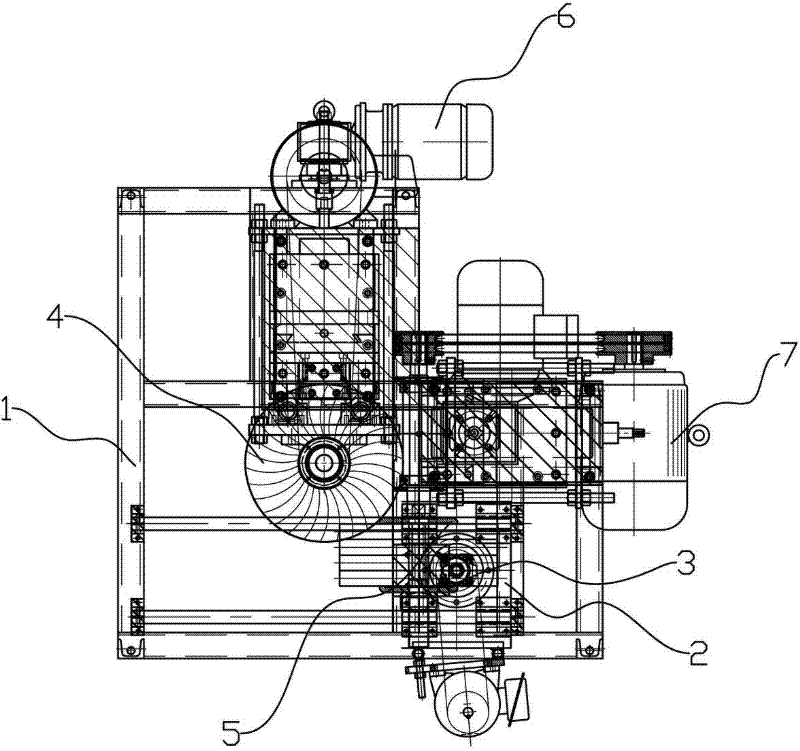

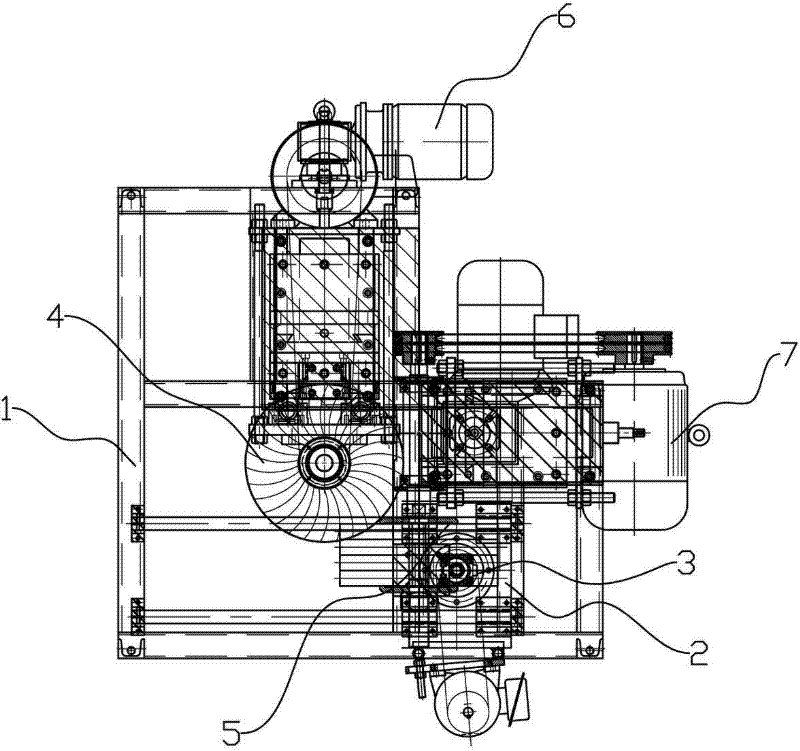

[0010] refer to figure 1 , figure 2 , a kind of double-sided polishing machine of the present invention, comprises frame 1, and described frame 1 is provided with movable workbench 2, and this movable workbench 2 is equipped with workpiece supporting base 3, and the lower part of movable workbench 2 is provided with drive The first power mechanism of its movement, the vertical surface polishing head 4 and the transverse surface polishing head 5 are respectively arranged on the top of the movable workbench 2, and the vertical surface polishing head 4 and the transverse surface polishing head 5 are respectively driven on the frame 1 First and second motors 6 and 7. Due to the adoption of the above-mentioned structure, the double-sided polishing machine is equipped with a vertical surface polishing head and a transverse surface polishing head respectively above the movable workbench, which can simultaneously polish the vertical surface and the transverse surface of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com