Chain clip cooling device for film producing machine

A technology for producing machinery and cooling devices, used in flat products, household appliances, other household appliances, etc., can solve the problems of scalding, pinching, low production yield of thin films, etc., to improve quality and yield, and avoid film rupture. Phenomenon, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

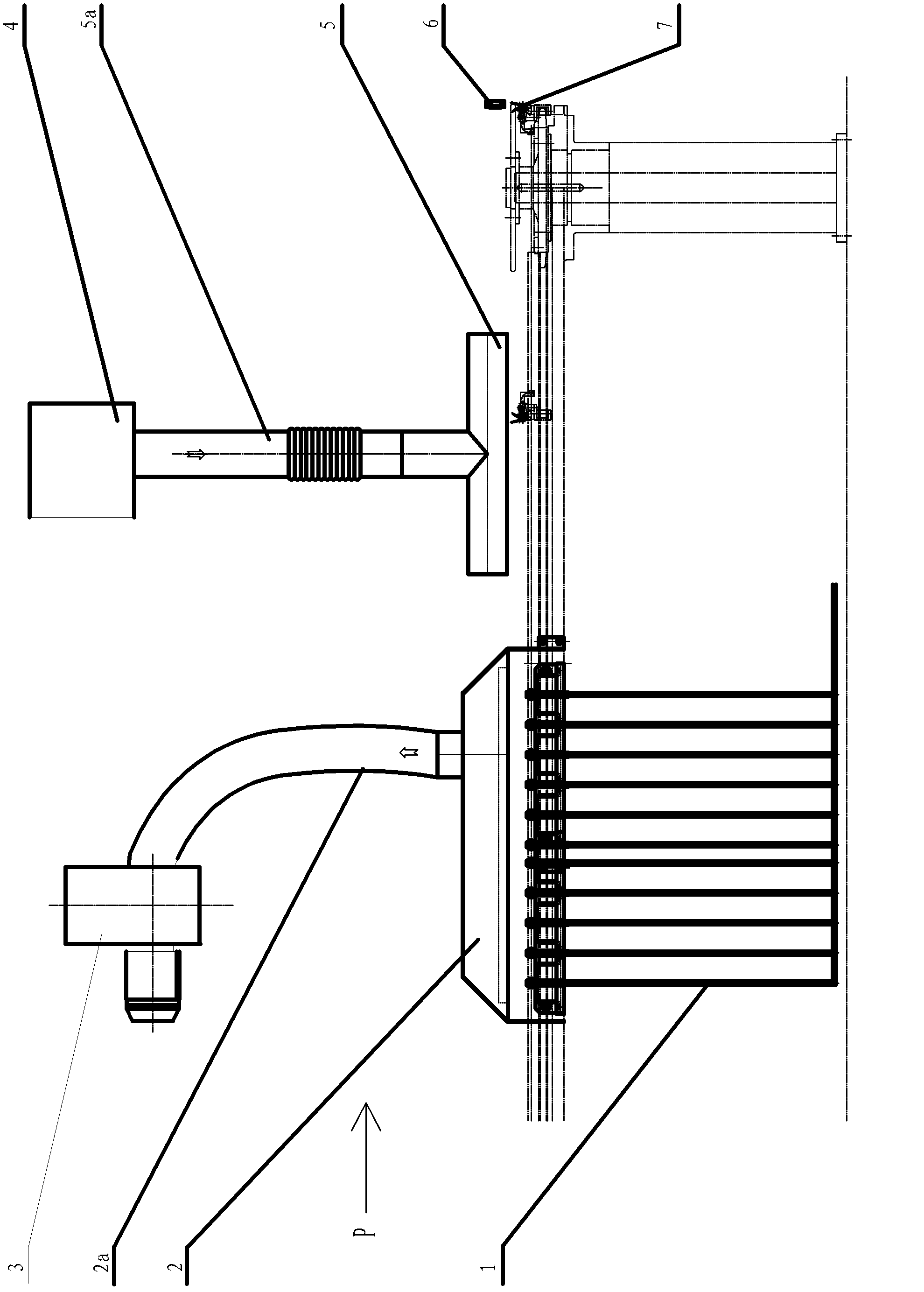

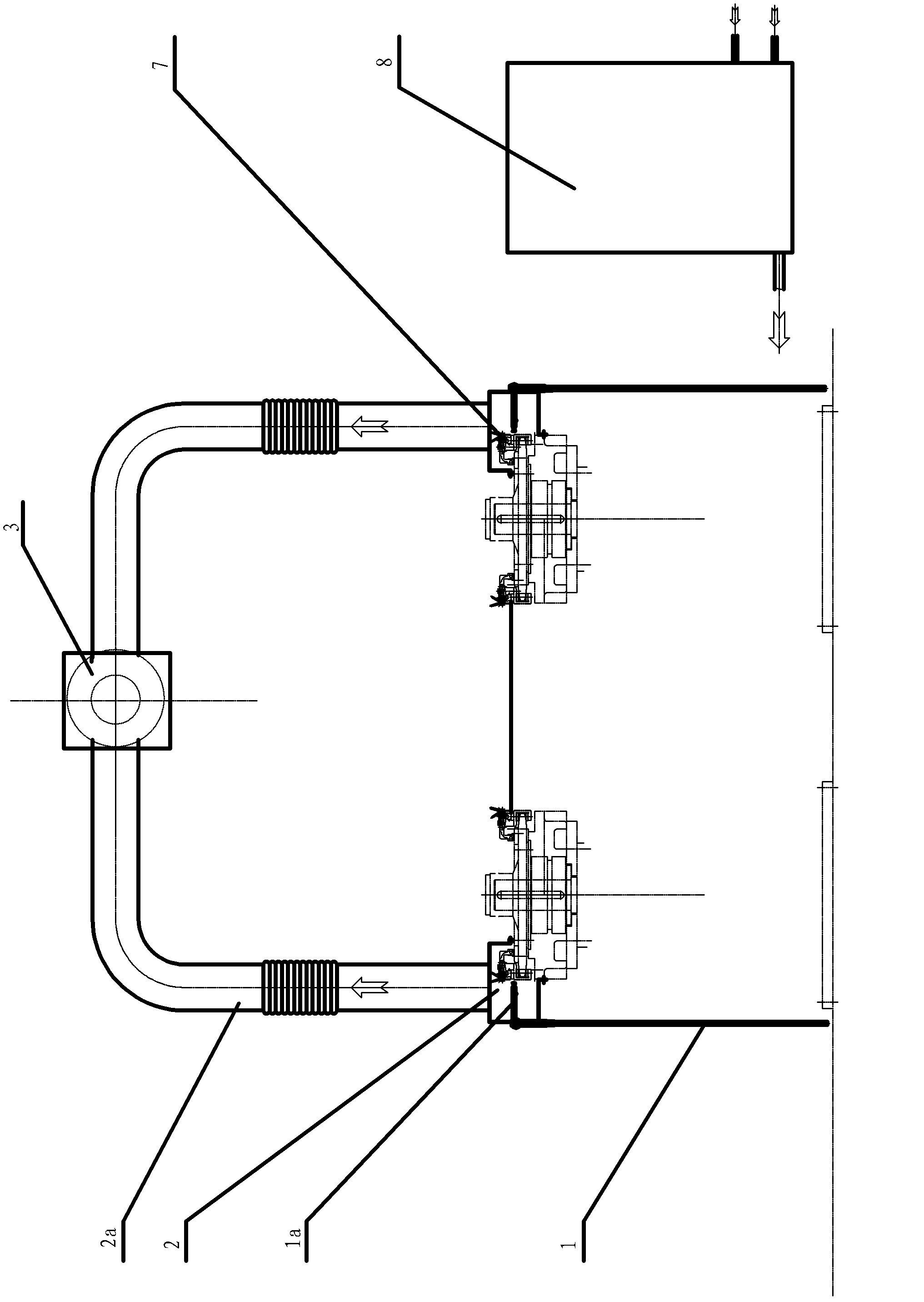

[0015] The chain clip cooling device of this film production machine is as follows: figure 1 with 2 As shown, the two chains of the chain clip 7 for clamping the film are respectively located on both sides of the film. After the film enters the clip, the running direction of the chain clip 7 is the same as that of the film. There is a group of cooling nozzles 1a on the outside of the circulating track of each chain installed with the chain clip 7, each group has 11 cooling nozzles 1a, and its spout is facing the surface of the chain clip 7, and each cooling nozzle 1a is connected to the cooling water pipe and / or Compressed air tube 1. The pitch of each cooling nozzle 1a was 100 mm. The distance between the spout of the cooling nozzle 1a and the clip surface of the chain clip 7 is 8-12mm, which can be adjusted.

[0016] There is a steam extraction hood 2 above each group of cooling nozzles 1a and the corresponding chain clip 7 running track of the group of cooling nozzles. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com