Automobile brake pedal

A technology of brake pedals and automobiles, which is applied in the direction of foot-operated starting devices, etc., which can solve the problems of unfavorable braking effect, affecting the use effect, and easy deformation, etc., and achieves the effect of facilitating space layout, not easy to deform, and small overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

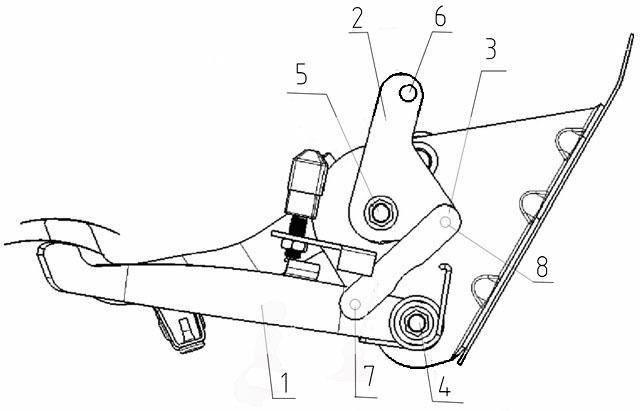

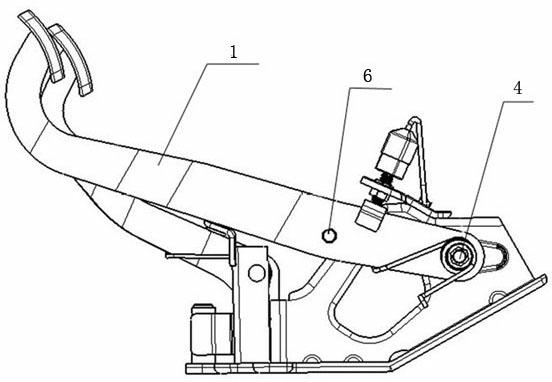

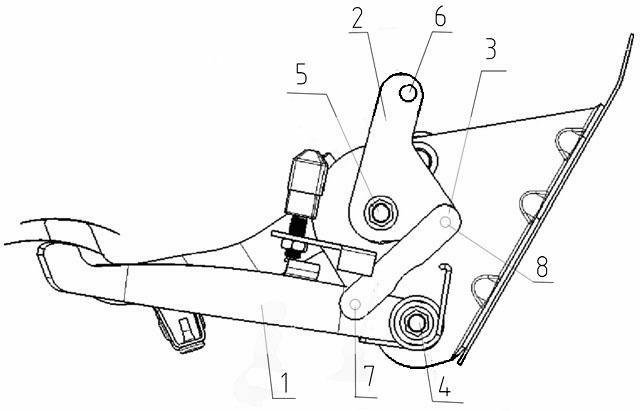

[0014] The present invention is described in further detail in conjunction with accompanying drawing now.

[0015] Such as figure 1 As shown, the automobile brake pedal includes a brake pedal swing arm 1 , a triangular swing lever 2 , a first brake pedal rotation shaft 4 , a second brake pedal rotation shaft 5 and a connecting rod 3 . The rear end of the brake pedal swing arm 1 is installed on the pedal bracket through the first brake pedal rotation shaft 4 . One corner of the triangular pendulum 2 is installed on the pedal bracket through the second brake pedal rotating shaft 5 . The connecting rod 5 is a straight rod, one end is connected with the middle part of the brake pedal swing arm 1 with a pin, and the other end is connected with the second angle of the triangular fork 2 with a pin. Moving master cylinder connection hole. The connection points of the first brake pedal rotation shaft 4, the second brake pedal rotation shaft 5 and the connecting rod 3 on the triangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com