Organosilane crosslinked polyethylene cable material and preparation process thereof

A silane cross-linking and preparation technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of complex granulation process and cable forming process, and achieve the effect of simplifying granulation process and cable forming process

Active Publication Date: 2012-05-09

RUGAO ZHONGRU CHEM

View PDF1 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The traditional production method in the past is a two-step method, that is, separate matrix masterbatch and catalytic cross-linking masterbatch. In the cable forming process, the two masterbatches are mixed and then cabled, and then undergo post-treatment, granulation process and cable forming process. complex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] 100 parts by mass of low-density polyethylene resin is used as a standard, and vinyltrimethoxysilane A171: 2.5-4 parts by mass, dicumyl peroxide DCP: 0.2-1 parts by mass, di-n-butyltin laurate: 0.2 parts by mass, Tetrakis-β-[3.5 di-tert-butyl-4-hydroxybenzene in pentacentritol propionate): 0.2 parts by mass.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an organosilane crosslinked polyethylene cable material, wherein the mass ratio of vinyl trimethoxy silane serving as a cross-linking agent, dicumyl peroxide serving as a cross-linking agent initiator, and butyltin dilaurate serving as a catalyst is (2.5-4): (0.2-1): 0.2. The preparation process is a one-step method, comprising the following steps of: mixing pre-mix materials and then directly granulating to obtain particles in a semi-cross-linking state, wherein the mixing temperature is 100-120 DEG C and the mixing speed is 960 rpm; and discharging at the mixing temperature of 140-145 DEG C by using a dual-screw machine at the speed of 300-400 RPM. The organosilane crosslinked polyethylene cable material and the preparation method thereof disclosed by the invention have the following advantages that: with adoption of the components, the organosilane crosslinked polyethylene cable material is prepared by using the one-step method, the granulating process of the cable material and the cable molding process are simplified.

Description

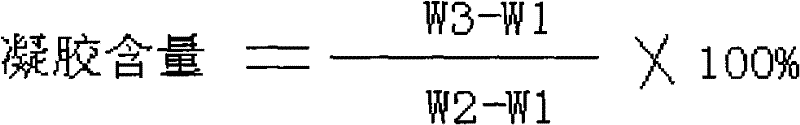

technical field [0001] The invention mainly relates to a silane cross-linked polyethylene cable material, specifically a silane cross-linked polyethylene cable material with low-density polyethylene resin as the main material; Granulation, the method of obtaining the silane cross-linked polyethylene cable material of the granular material in the semi-cross-linked state. Background technique [0002] The traditional production method in the past is a two-step method, that is, separate matrix masterbatch and catalytic cross-linking masterbatch. In the cable forming process, the two masterbatches are mixed and then cabled, and then undergo post-treatment, granulation process and cable forming process. complex. Contents of the invention [0003] The main task of the present invention is to provide a silane cross-linked polyethylene cable material, specifically a silane cross-linked polyethylene cable material whose gel content can be controlled below 30%. [0004] In order t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08K5/5425C08J3/24H01B3/44

Inventor 蔡可建黄宏才张海波周荣敬

Owner RUGAO ZHONGRU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com