Crude oil deep vacuum distillation process and system

A process method and deep drawing technology are applied in the crude oil vacuum deep drawing process method and system for improving the extraction rate, and the crude oil distillation method and system field, which can solve the problems of unfavorable vacuum distillation column operation, safety design and installation difficulty, etc. problems, to improve the effect of gas-liquid separation, optimize process design, and improve the effect of flash evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

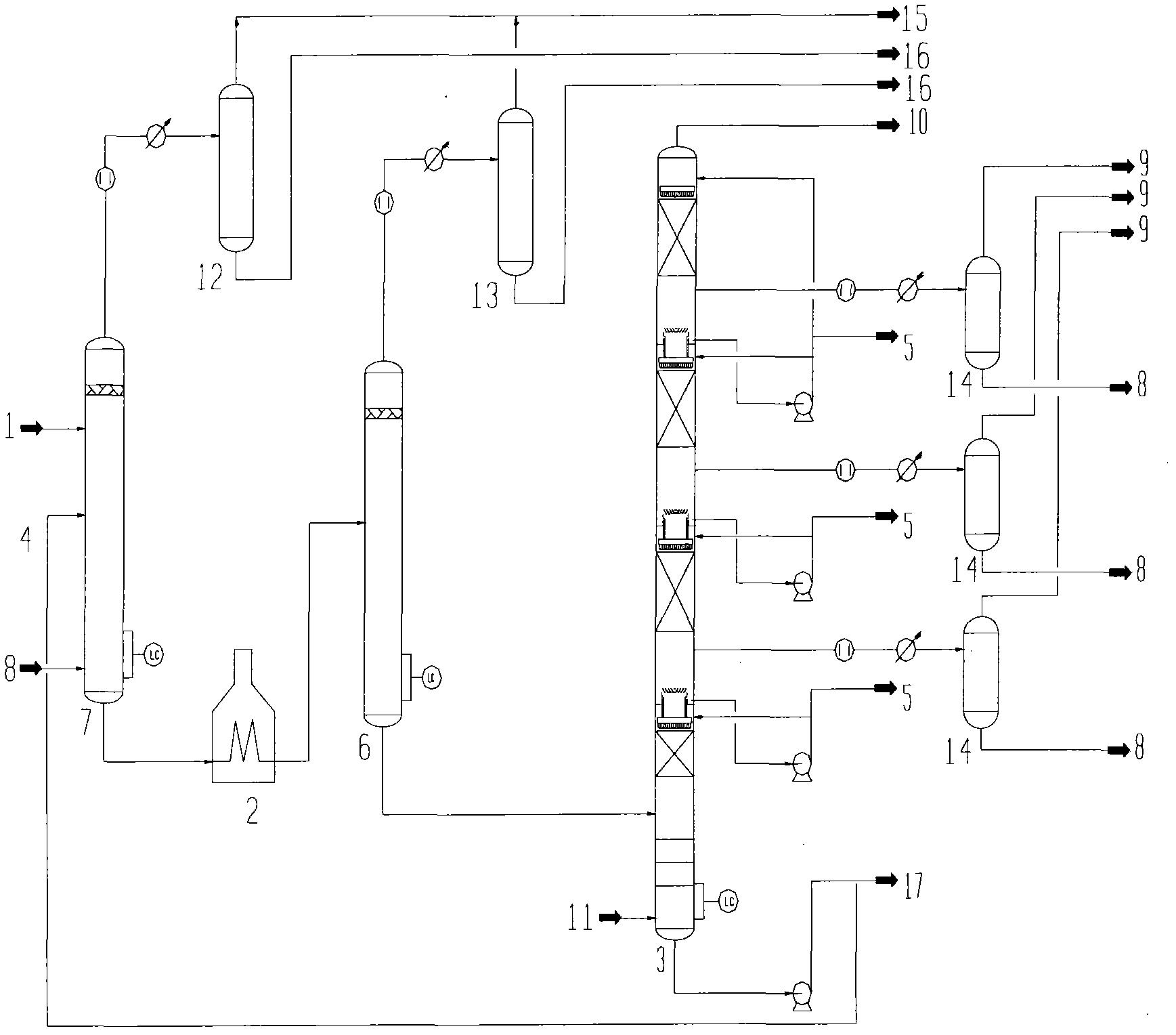

[0043] combined with figure 1 , The technical process of the crude oil vacuum deep drawing process of the present invention is that the constant bottom oil 1 and the circulating vacuum residue 4 are mixed into the first-stage flash tower 7 . Under the stripping action of high-temperature hydrogen, the relatively lighter components flash out, and the gas phase, that is, a flash gas enters a flash gas liquid separation tank 12 after heat exchange, condensation and cooling, and the liquid phase of the liquid separation tank is used as the flash top product 16 discharge; the gas phase of the liquid separation tank is connected to the vacuum system 15 to control the pressure of the primary flash tower at 5kPa~20kPa. The liquid phase at the bottom of the primary flash tower is heated to 390°C to 420°C and enters the secondary flash tower 6. The gas phase at the top of the tower enters the secondary flash gas liquid separation tank 13 after heat exchange, condensation and cooling, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com