Portable well mouth sealer

A wellhead sealer, a portable technology, applied in the directions of sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problem that the continuous sucker rod can not be used to lift the plunger, the wellhead sealing function cannot be effectively achieved, and the cost is increased. and other problems, to achieve the effect of significant oil increase effect, simple structure, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

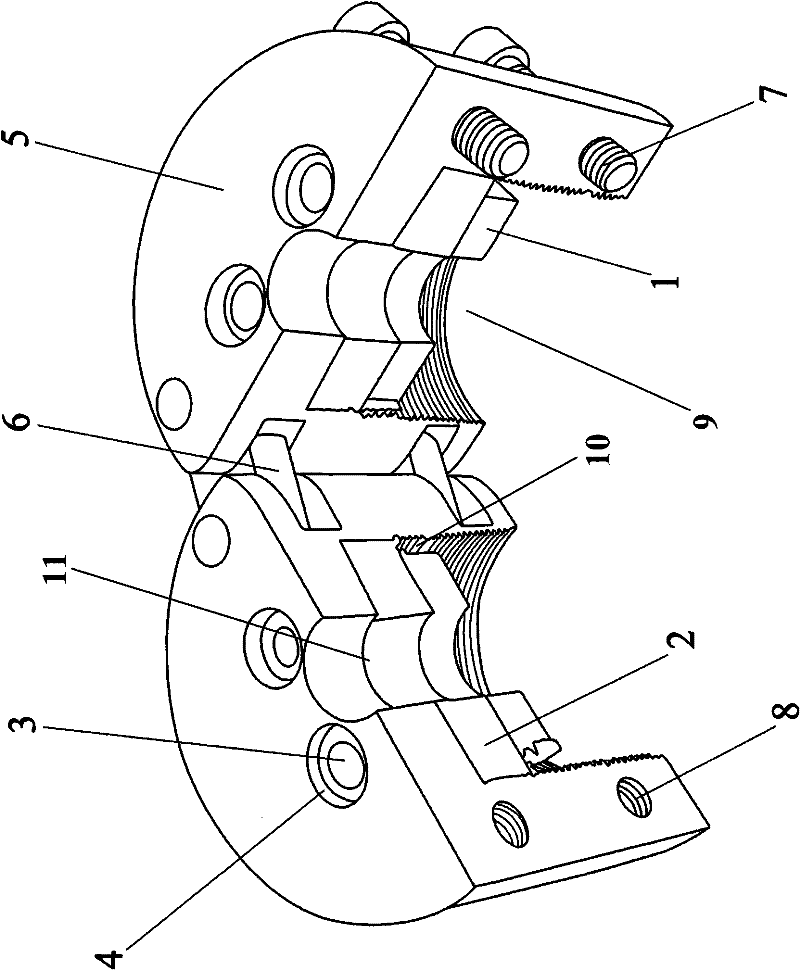

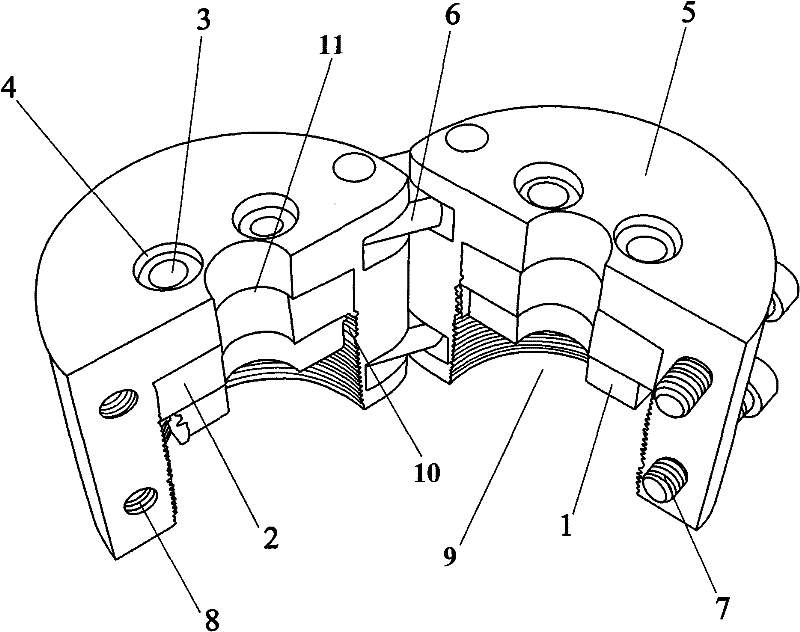

[0032] Next, the shape and structure of an embodiment of the portable wellhead sealer of the present invention will be described with reference to the accompanying drawings.

[0033] Such as figure 1 As shown, the portable wellhead sealer of the present invention includes a pressure-bearing rigid body 5, a polished rod or sucker rod packaging hole 11, a sealing cavity 9 at the top of the oil tree, a sealing groove 10, a sealing pressure plate 1, a sealing rubber core 2, and a sealing and locking mechanism .

[0034] The pressure-bearing rigid body 5 is composed of two corresponding cylindrical parts, and the two cylindrical parts can be opened and closed with the permanent connection end between them as an axis. When the two cylinders are partially closed, they form a complete cylindrical pressure-bearing rigid body. Here, the cross-sectional shape of the pressure-bearing rigid body 5 can be circular, rectangular, triangular or other shapes. The two cylindrical parts are for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com