Air-conditioning system waste heat recovery method and system thereof

A waste heat recovery and air-conditioning system technology, applied in air-conditioning systems, ventilation systems, heating methods, etc., can solve the problems that the heat of the refrigerant is not used reasonably, the return of liquid refrigerant is not suitable, and the energy saving and consumption reduction of the air-conditioning system are not realized. The effect of increasing the temperature, expanding the heat exchange area, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

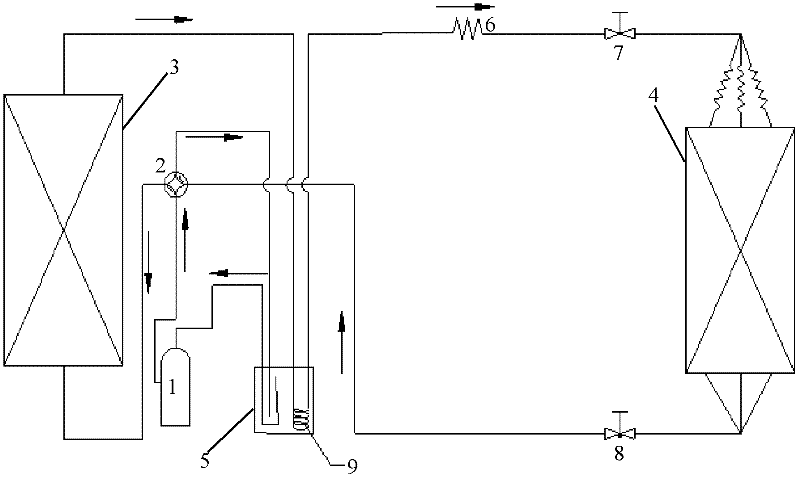

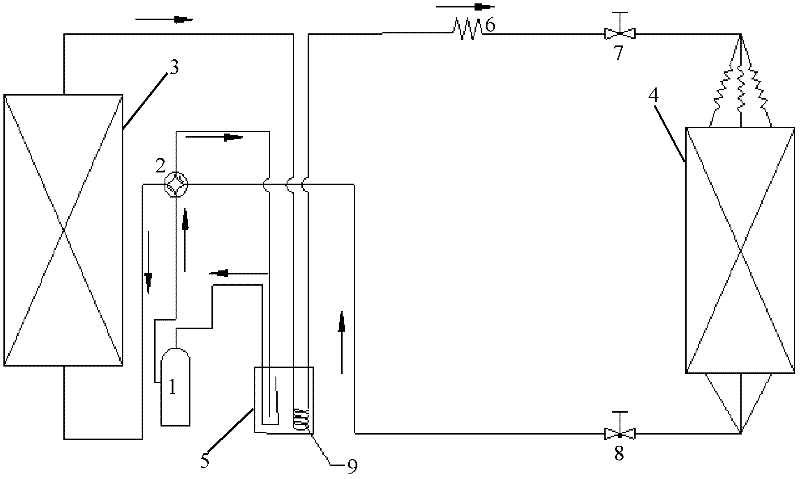

[0020] Considering the problems existing in the related art, the present invention provides a method and device for recovering waste heat of an air-conditioning system. Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. It should be understood that the embodiments described below by referring to the figures are exemplary only for explaining the present invention, and should not be construed as limiting the present invention.

[0021] figure 1 It is a schematic diagram of a method for recovering waste heat from an air-conditioning system according to the present invention, such as figure 1 as shown,

[0022] The gaseous refrigerant delivered by the compressor 1 is exothermicly liquefied in the condensing device 3;

[0023] The liquid refrigerant in the condensing device 3 is transported to the throttling device 6 through the recovery device 5, and after being processed into a gas-liquid mixed refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com