Method, device and system for controlling drying roller and drying device

A technology of control equipment and control method, applied in drying, lighting and heating equipment, drying solid materials, etc., can solve the problem of slow adjustment response process, poor sand drying effect, inability to quickly and effectively control the water content of sand, etc. problems, to achieve the effects of fast adjustment response, improved production efficiency, and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

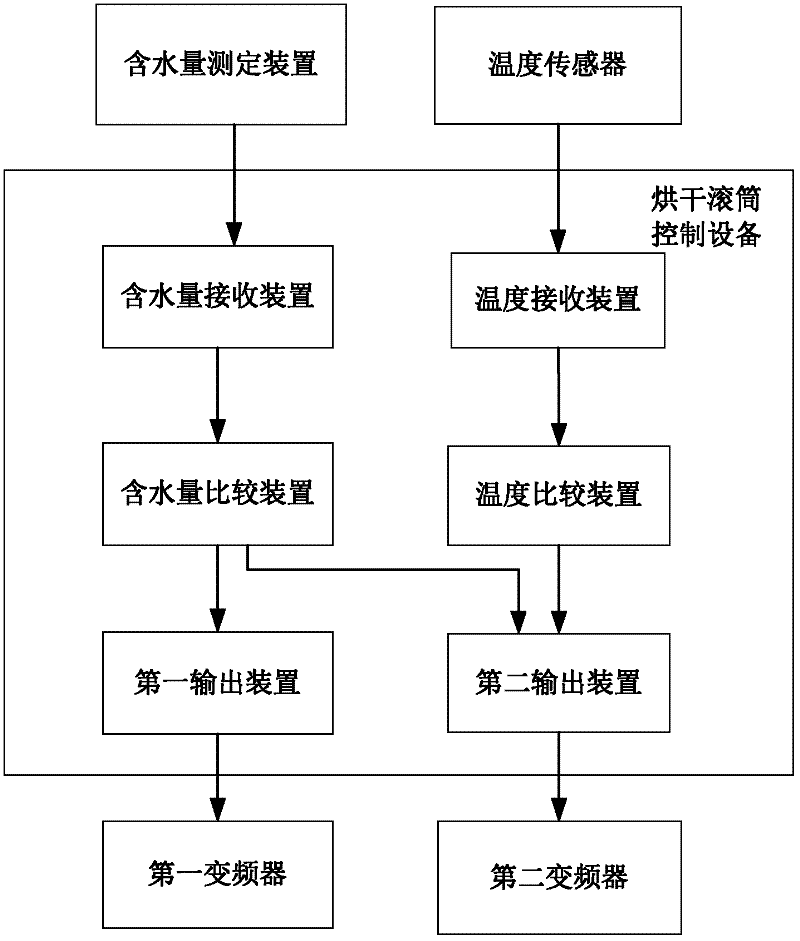

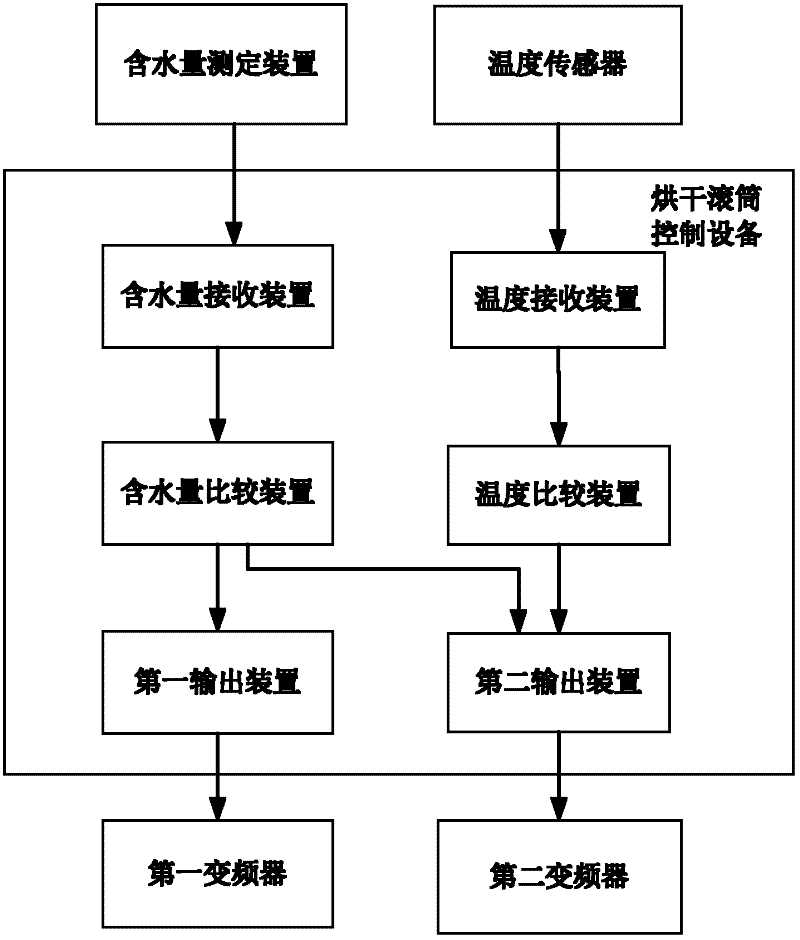

[0022] In order to prevent the exhaust gas of the drying drum from being too high and cause the dust-proof bag to burn and cause danger, the temperature inside the drying drum can also be monitored. According to a preferred embodiment, the method further includes: receiving a signal representing the temperature in the drying drum, and outputting a temperature value; comparing the temperature value with a given threshold, and outputting a temperature comparison result; if the temperature comparison result is If the temperature value is greater than the given threshold, the coal feeder is controlled to reduce the coal feed rate. Therefore, when the temperature in the drying drum is too high, the temperature in the drying drum can be reduced by reducing the coal feeding amount of the coal feeder.

[0023] According to a preferred embodiment, the coal feeder's coal feed rate can be controlled to increase or decrease according to the water content comparison result, and the coal fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com