Heat teratment apparatus

A technology for heat treatment devices and objects to be processed, which can be used in waste heat treatment, maintenance of heating chambers, lighting and heating equipment, etc. It can solve the problems of large-scale devices and high costs, and achieve the effect of suppressing large-scale and cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

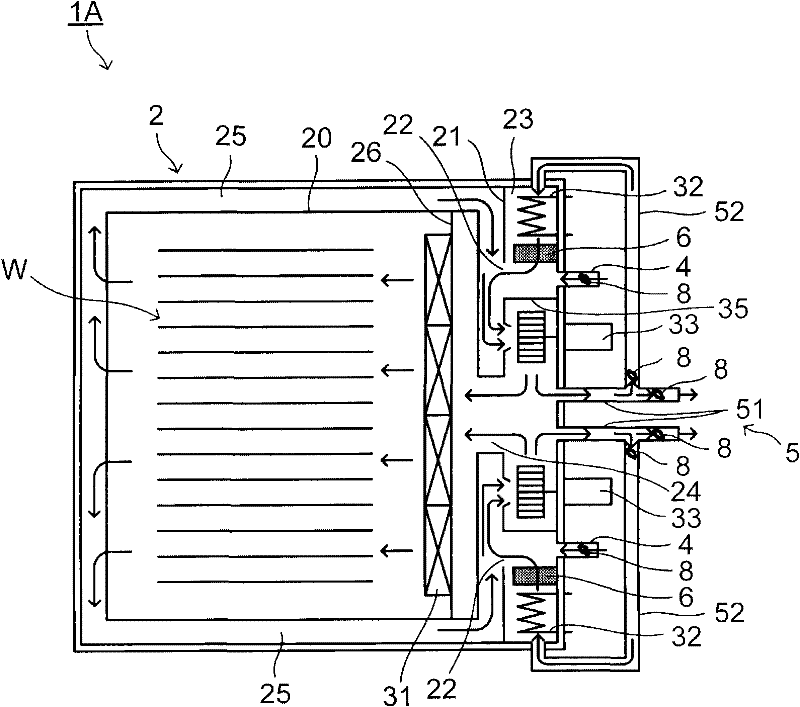

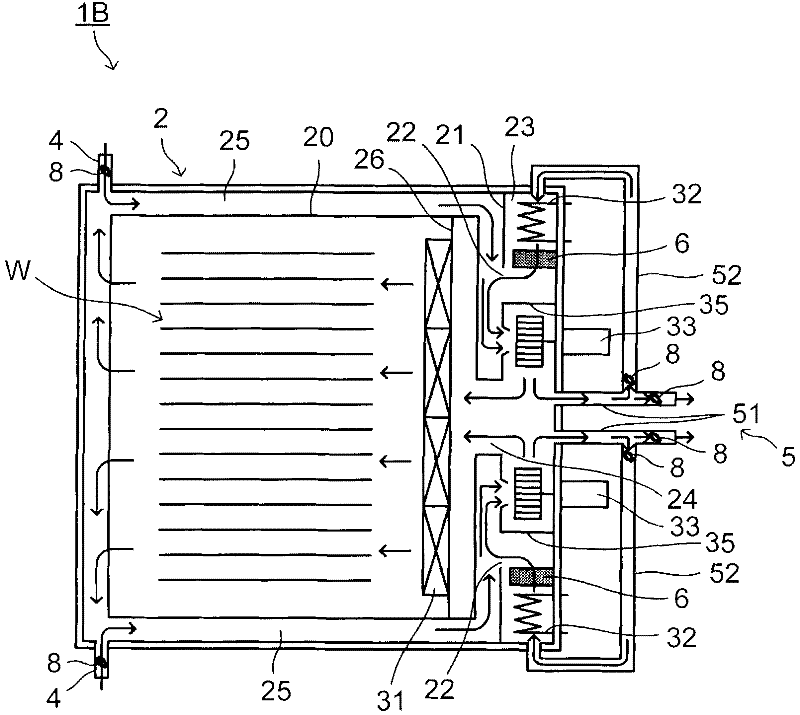

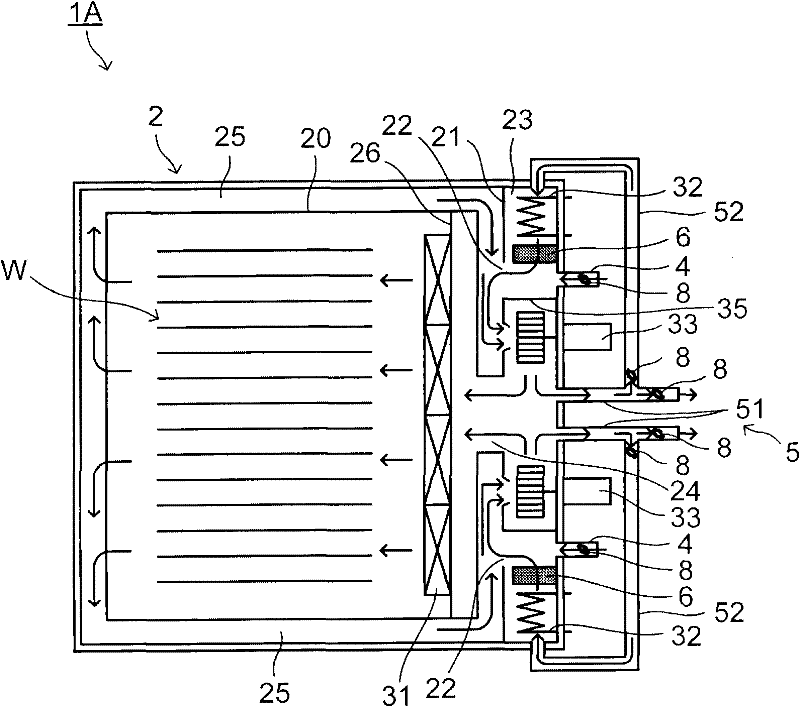

[0016] Refer below figure 1 The outline of the heat treatment apparatus according to the embodiment of the present invention will be described. The heat treatment apparatus 1A includes an adiabatic chamber 2, and a space forming the adiabatic chamber 2 is surrounded by adiabatic walls. The adiabatic chamber 2 has a heat treatment furnace (heat treatment unit) 20 , an air conditioner 23 , and passages connecting the heat treatment furnace 20 and the air conditioner 23 (air supply passage 24 and return passage 25 described later).

[0017] The inside of the heat insulating chamber 2 is partitioned by a partition 21 . In the space inside the adiabatic chamber 2 , the heat treatment furnace 20 is arranged on the left side of the partition 21 , and the air conditioner 23 is arranged on the right side of the partition 21 . An opening 22 is formed on the partition plate 21 , through which the air flow that returns to the air-conditioning unit 23 through the return passage 5 describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com