Moving contact device of relay

A technology of moving contacts and relays, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of low current carrying capacity, low working reliability, unfavorable breaking of large currents, etc., to meet the requirements of safe isolation and good economy. efficiency, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

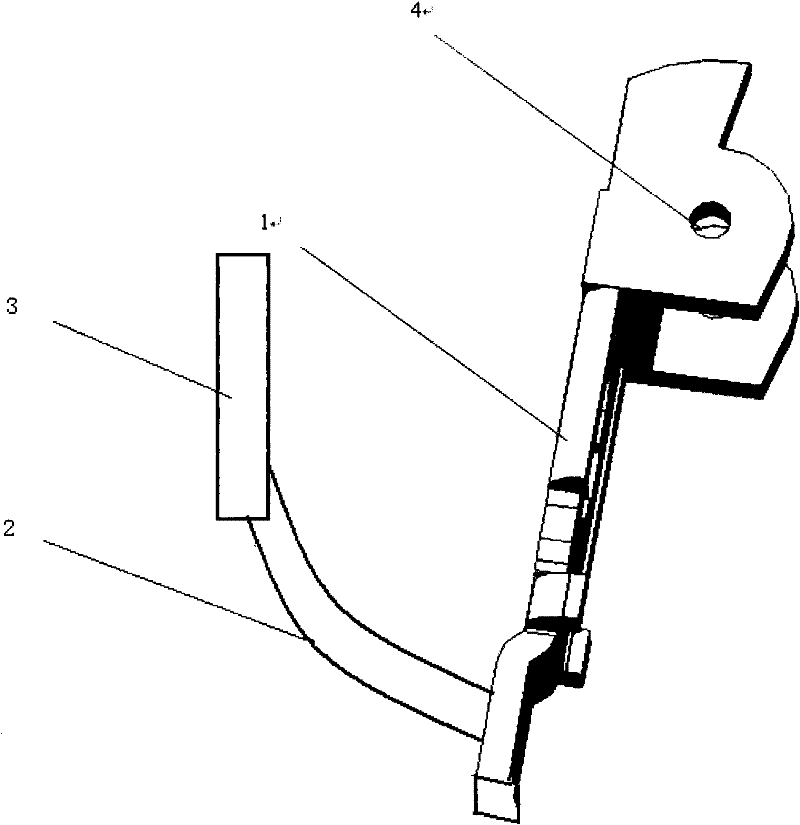

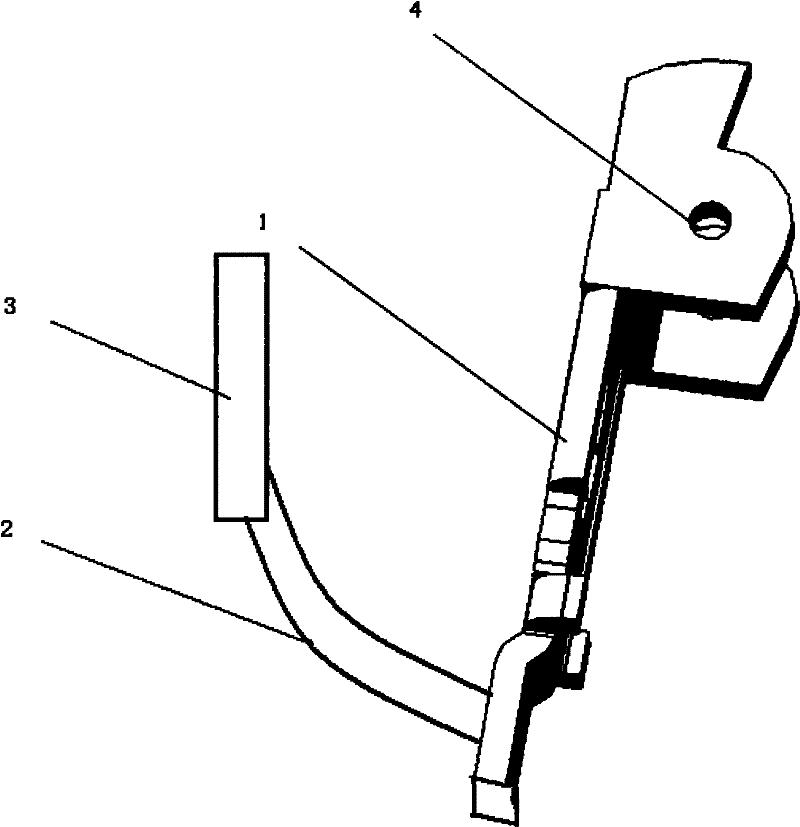

[0024] The main structure of the moving contact device provided by the present invention includes a moving contact body 1 , a non-ferrous metal flexible wire 2 and a terminal 3 . Such as figure 1 As shown, the moving contact body 1 is a sheet-shaped conductive material, and its front end is connected to the non-ferrous metal soft wire 2 by welding.

[0025] The material used for the moving contact body is copper, and other materials such as iron can also be used. When other materials are used, a conductive contact with a resistivity lower than that of the movable contact body needs to be connected to the movable contact body, and the non-ferrous metal flexible wire 2 is connected to the conductive contact by riveting or welding. The other end of the non-ferrous metal flexible wire 2 is connected to the terminal 3, and may also be connected to the rear end of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com