Bit replacing device for excavating machine

A roadheader and cutter head technology, which is applied in the field of cutter head replacement devices, can solve problems such as large rotational driving force, achieve a large working space, reduce manufacturing costs, and ensure the effect of working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

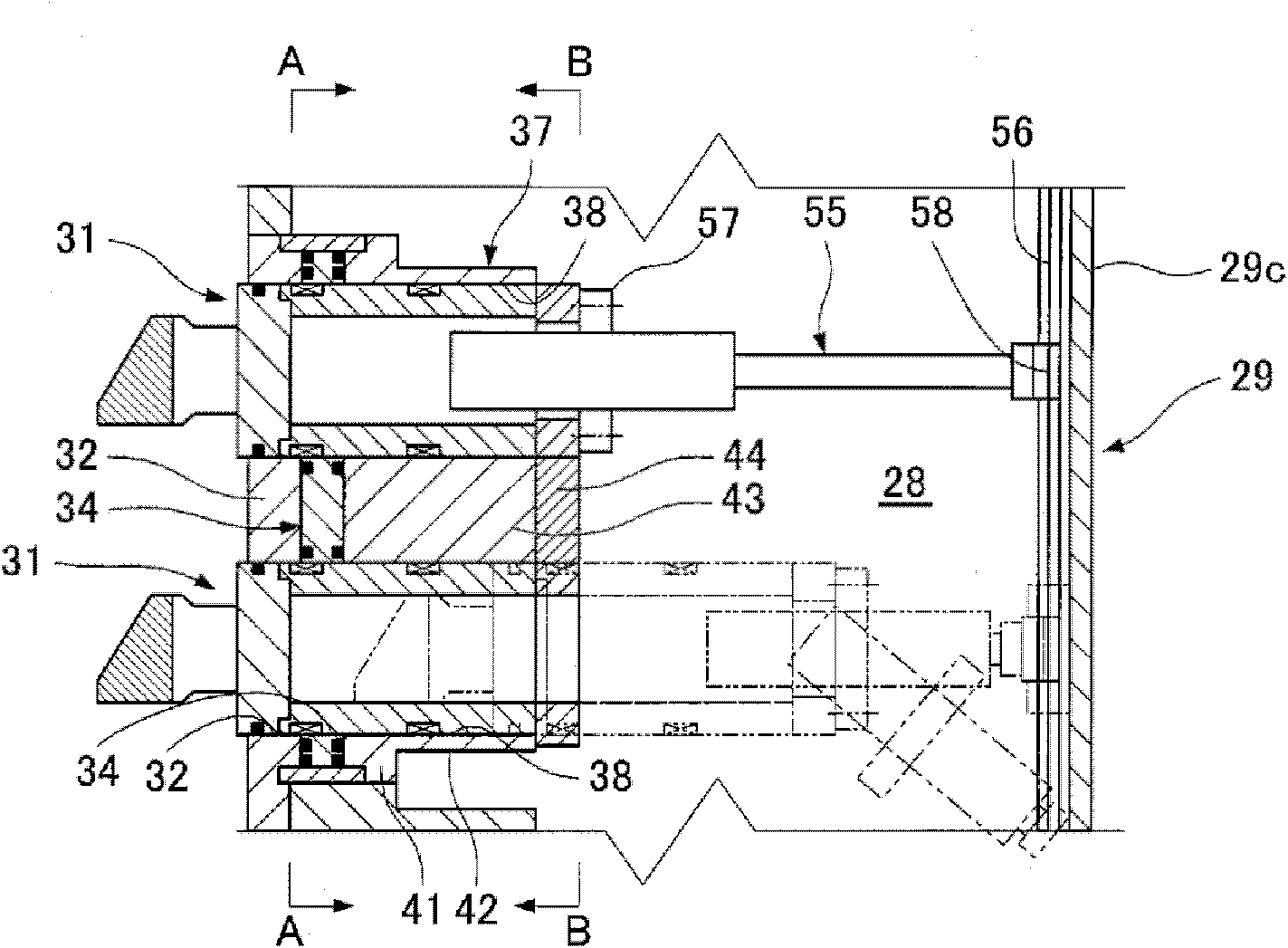

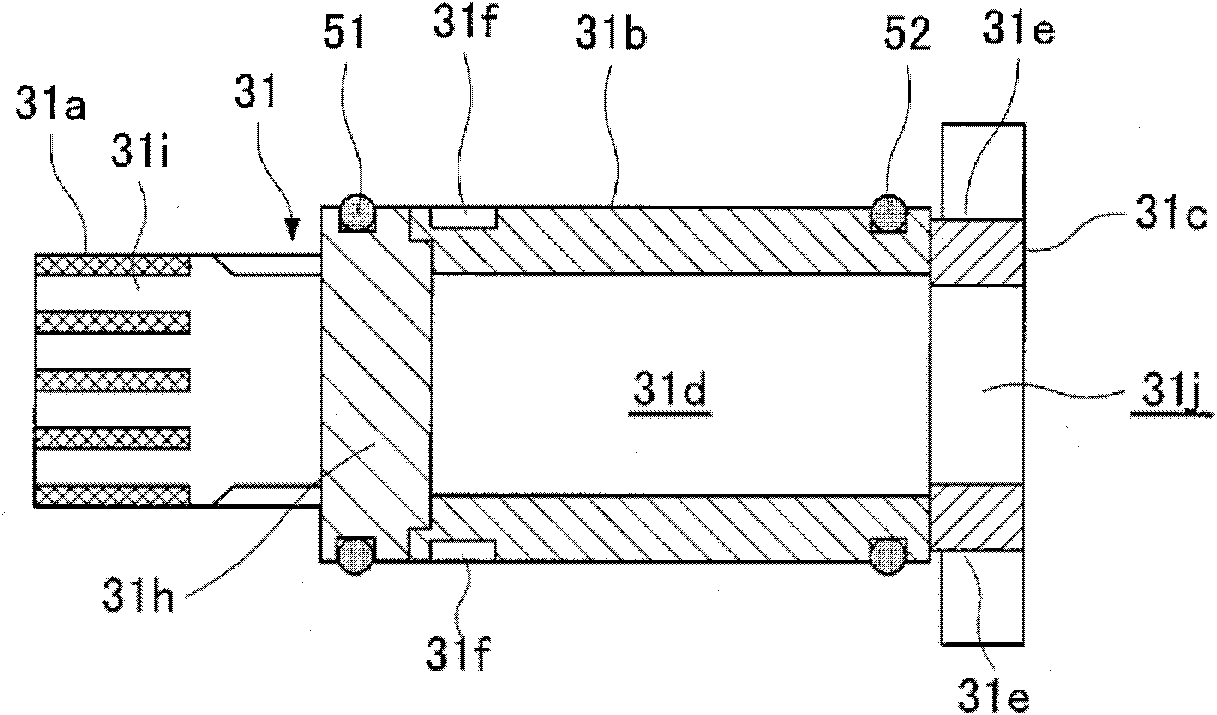

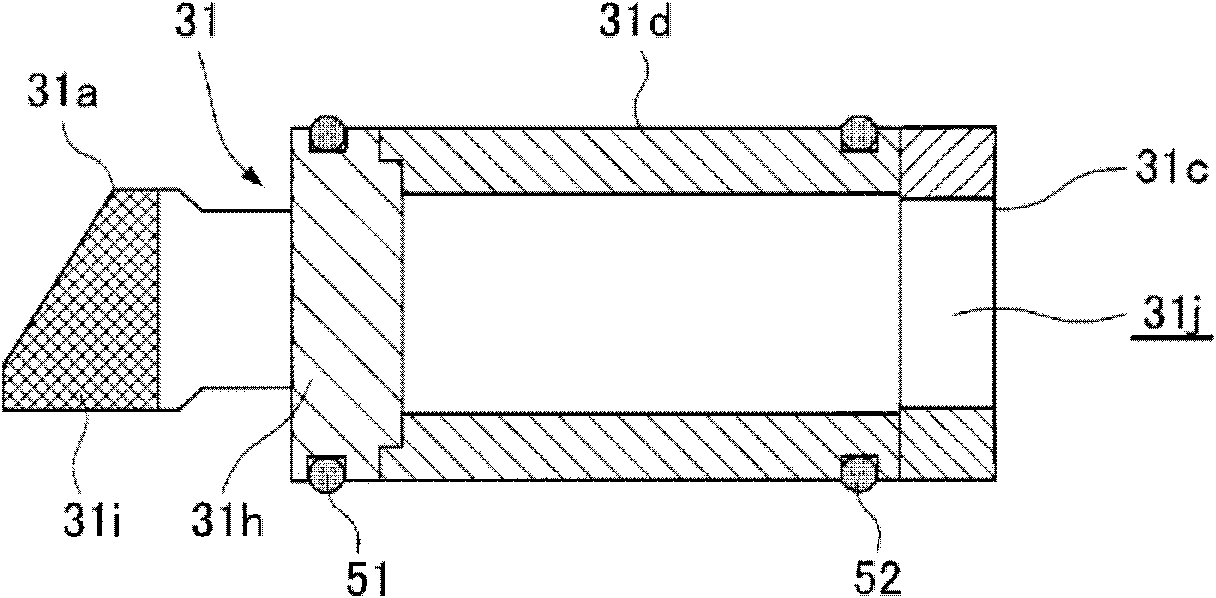

[0034] refer to Figure 1A , Figure 1B ~ Figure 10A , Figure 10B Example 1 will be described.

[0035] Such as image 3 As shown, in the front part of the cylindrical shield main body (roadheader main body) 11, a pressure bulkhead 12 is provided to maintain the earth pressure of the excavation surface caving, and the rotary ring member 14 is supported by the rotary bearing 13 on the pressure bulkhead 12 It can rotate freely around the shield axis O (the axis of the roadheader). Further, a circular cutter head 16 is supported on the front ends of a plurality of support legs 15 protruding forward from the rotating ring member 14 . A cutterhead driving device 17 is arranged at the rear of the pressure bulkhead 12, and the cutterhead driving device 17 drives the cutterhead 16 to rotate. The cutter head driving device 17 includes: a ring gear 17a provided on the back of the rotating ring member 14; a plurality of driving pinions 17b meshed with the ring gear 17a; and a plural...

Embodiment 2

[0084] (Bit replacement unit)

[0085] In the bit replacement unit 30 of the above-mentioned embodiment, two replacement bits 31 (openings 33 ) are arranged on the radial axis RL, but as Figure 11A , Figure 11B As shown, in this bit replacement unit 70 , three replacement bits 31 are arranged at equal intervals (equal angles) around the switch axis OC. That is, in the cutter head replacement unit 70, an opening 33, a valve port 35, and a cutter head guide hole 38 are respectively formed at intervals of 120° on the same circular arc centered on the switch axis OC, and three replacement parts are provided. Use cutter head 31. The above-mentioned replacement cutter heads 31 are respectively arranged to be inclined α° toward the outer peripheral side of the front portion, and since it is the same as the above-mentioned embodiment except that the gate opening and closing device 36 makes the gate plate 34 reciprocate in the range of 120°, the same method is adopted. Reference n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com