Blanking method and system for automobile plate

A technology for automobile sheet and blanking, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve the problems of sheet taking away, difficulty in feeding pinch rollers, and easy straining of pinch rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

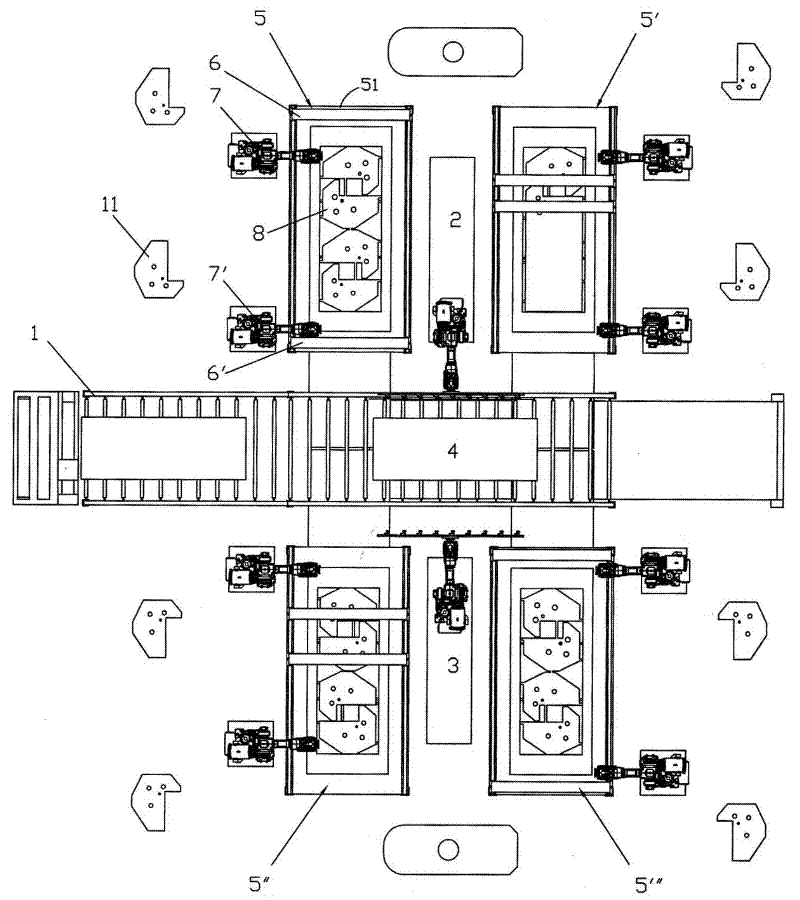

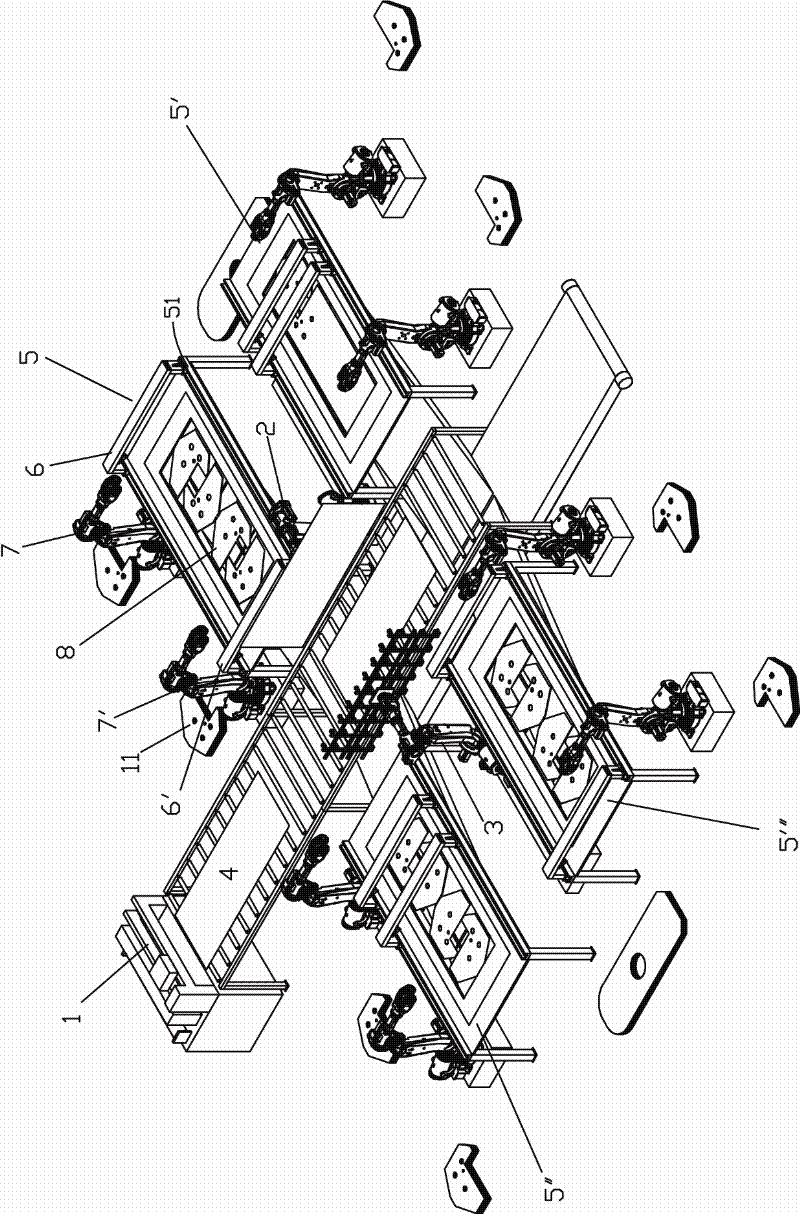

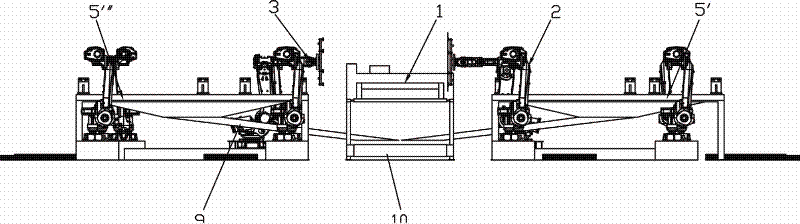

[0049] see Figure 1 ~ Figure 4 , an embodiment of the present invention. In this embodiment, the blanking system for automobile panels of the present invention includes a material assembly conveyor chain 1; two handling robots 2, 3 are arranged on one side of the material assembly conveyor chain 1; four cutting work units 5, 5 ', 5", 5'", located on the side of the handling robot 2, 3; cutting work unit 5 (take cutting work unit 5 as an example, other cutting work units are the same) set two laser cutting machines 6, 6'; cutting work Two stacking robots 7 and 7' are arranged on the side of unit 5 (taking cutting unit 5 as an example, the same below); the liner mold 8 is set in the cutting unit 5, and the liner mold 8 is hollowed out at the corresponding waste material Blanking hole 81, the size of the blanking hole is larger than the size of the actual cutting waste blanking; according to the discharge of the sheet material, the group material 4 is placed on the lining mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com