Embedded-method anti-leakage technology for high-pressure water and gas conveyance

An embedded, high-pressure technology, used in flange connection, gas/liquid distribution and storage, pipes/pipe joints/fittings, etc., which can solve problems such as breakdown, leakage, and easy disassembly of flanges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

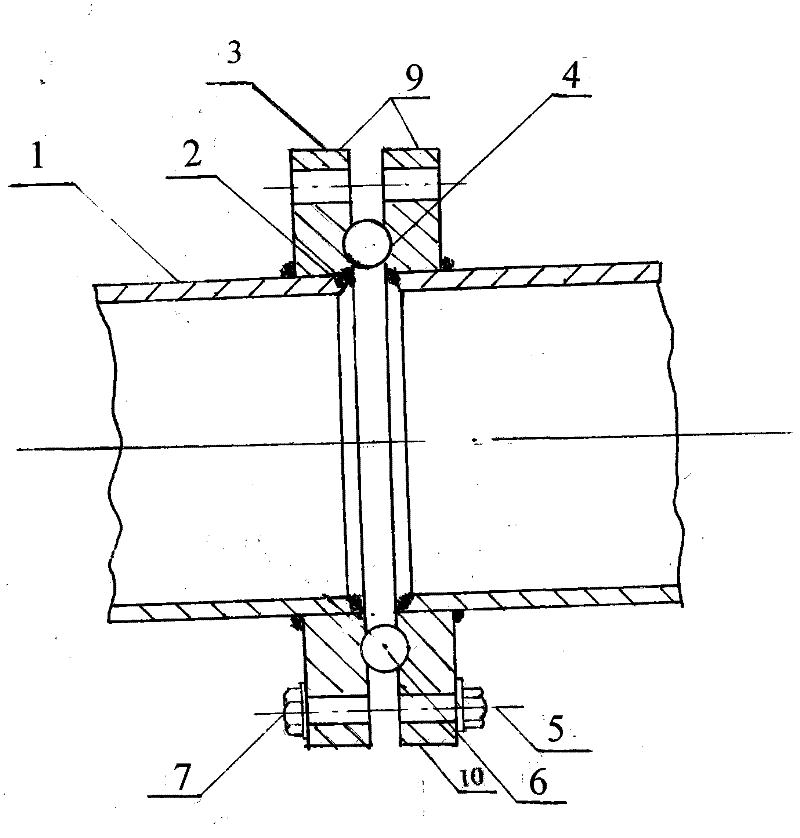

[0013] 1. In figure 1 Among them, the flange (3) is steel plate material, according to the diameter of the outer circle of the steel pipe (1), the inner hole and the outer circle (10) of the flange (3) are processed by oxygen cutting, and then the bolt holes (5) are drilled , carry out rough turning, and then finish turning the groove (4) of the sealing ring (6), and then put the processed flange (3) on the outer circle (10) of the steel pipe (1), and the two corresponding front and rear Block flange (9) adopts flat welding (2) welding connection with steel pipe (1), and a pair of flanges (9) at both ends of the front and rear pipes penetrate screw holes (5) with bolts (7) and connect.

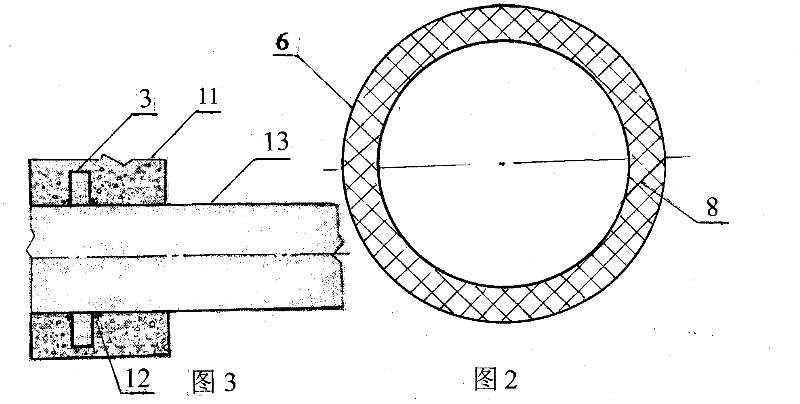

[0014] 2. In figure 2 In the process, the O-ring (6) is embedded in the groove (4) of the fine-turning sealing ring (6), and the bolts are tightened to connect to achieve the purpose of sealing. The O-ring (6) can be customized from the manufacturer , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com