Swirl setting apparatus for a burner

A technology for burners and adjusting rods, which is applied in the direction of burners, gas fuel burners, and powder fuel burners, etc. It can solve the problems of divergence, flexible pipes cannot be controlled arbitrarily and accurately, and achieve space-saving and good cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

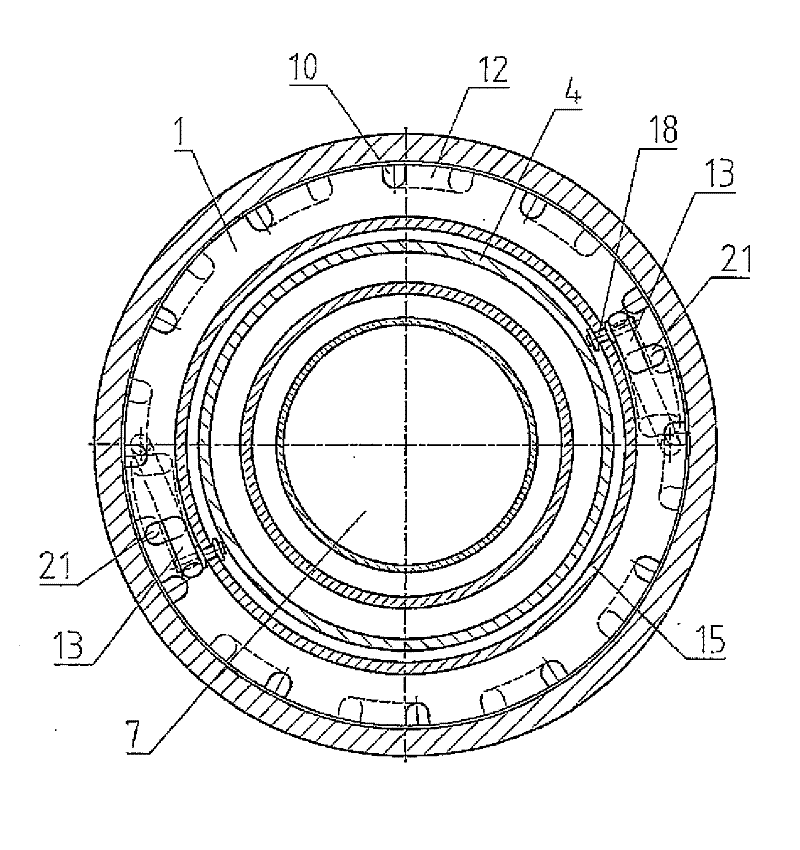

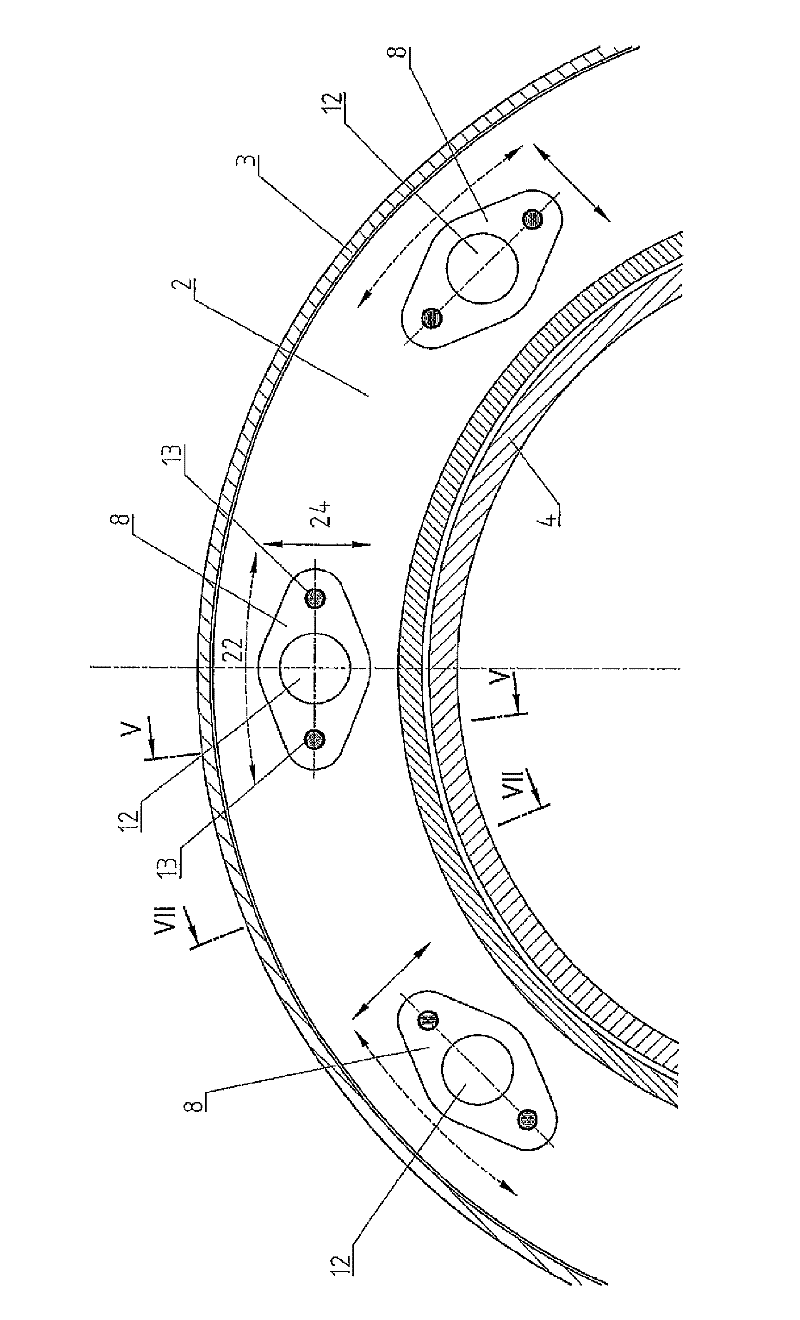

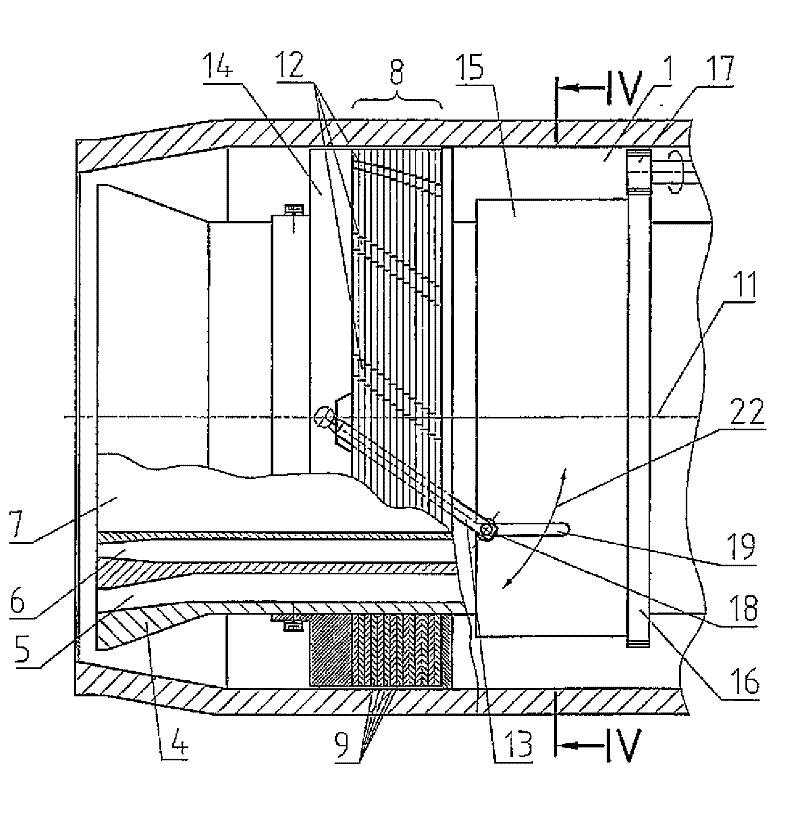

[0040] Such as figure 1 The flexible swirl adjustment shown is located in the annular primary air channel 1 at a distance from the burner outlet nozzle 2 . The primary air channel 1 is delimited here by the burner housing 3 and the cylindrical wall 4 . The other channels 5 , 6 and 7 for fuel are located inside the primary air channel 1 .

[0041] The swirl adjustment device arranged in the primary air channel 1 consists of a guide vane set 8 which is composed of a plurality of guide vanes 9 combined together. The baffle 9 generally has gaps 10 distributed on the circumference, and they are figure 1 and 2 The shown basic positions of the swirl adjustment devices are centered relative to each other, so that a straight course of the channel 12 results, parallel to the burner axis 11 . To adjust the swirl, there are adjusting levers 13 diametrically opposite each other with respect to the axis 11 , the ends of which face the burner nozzle 2 are rotatably mounted in a sealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com