Water screen environment-friendly paint spraying booth

A technology of spray booth and water curtain, which is applied in the direction of coating, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of polluting the environment and endangering the health of construction workers, so as to reduce air pollution and improve painting quality and work efficiency , easy to collect and process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

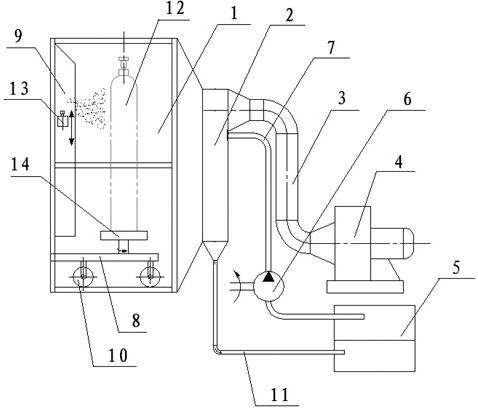

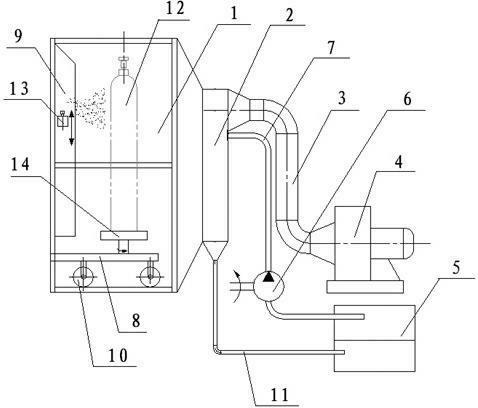

[0010] Such as figure 1 As shown, a water curtain type environmental protection spray booth, its main body is a spray booth 1, a paint spray device 9 is arranged in the paint spray booth 1, and a paint spray nozzle 13 is arranged on the paint spray booth 9, and it is characterized in that: one side of the paint spray booth 1 A water curtain room 2 is installed, and there are three connection ports on the water curtain room 2, and the three connection ports are respectively connected with the air induction pipe 3, the water pump 6, and the paint outlet pipe 11, the air induction pipe 3 is connected with the fan 4, and the paint outlet pipe 11 is connected with the pool 5, and the water pump 6 is connected with the water curtain chamber 2 and the pool 5 through the water pipe 7 respectively.

[0011] Its working principle is: when spraying paint on the workpiece 12, the flowing water delivered by the water pump forms a water curtain in the water curtain chamber, and the spray pa...

Embodiment 2

[0013] It is the same as the water curtain-type environmental protection spray booth in Embodiment 1, the difference is that: a pallet truck 8 is also installed in the paint spray booth 1, and a rotary disc 14 is arranged on the pallet truck 8, and the rotary disc 14 is connected with the power The device is connected and realizes uniform rotation. The turntable drives the workpiece to rotate at a constant speed, so as to achieve the purpose of uniform and comprehensive painting.

Embodiment 3

[0015] It is different from the water-curtain-type environmental protection spray booth in Embodiment 1 in that: the pallet truck 8 is provided with rollers 10 under it. With the rollers 10, the pallet truck can move easily, thereby facilitating the loading and unloading of workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com