Preparation method of novel conductive exothermic carbon fiber composite material

A composite material and carbon fiber technology, which is applied in the direction of film/sheet adhesive, device for coating liquid on the surface, coating, etc., can solve the inconvenience of industrial production, high temperature resistance, resistance to fire and demolition, high strength and other properties Poor, unable to meet industrial production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

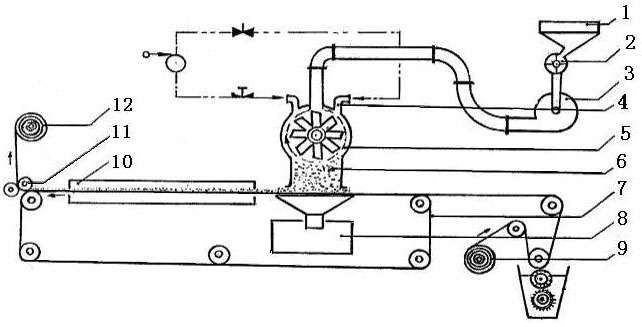

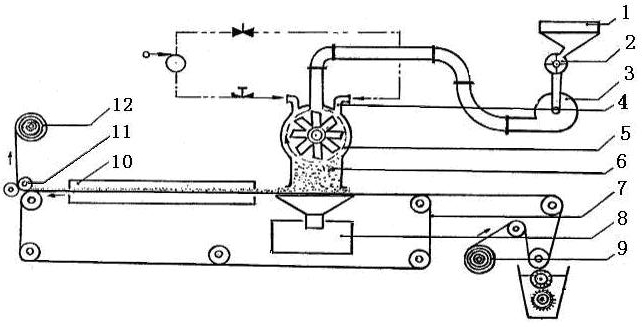

[0010] When the present invention is powered on, air is used as the medium, the carbon fiber is chopped to 3-11 mm, dried at 100°C for 60 minutes, sent into the trough 1 and initially dispersed by the decomposer 2; sent into the gyrator 4 by the blower 3 for further dispersion, The settling adjuster 5 with positive electric field sends the fully dispersed carbon fiber quantitatively to the conveyor belt 7, and the positively charged carbon fiber 6 is adsorbed on the surface of the negatively charged substrate 9 under the action of the electrostatic field force. Through the hot air drying device 10, the calender trimming roller 11 is wound up into a fiber composite material 12, and the redundant carbon fiber is recovered and reused by the recycler 8 during compounding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com