Method and device for cleaning mass flowmeter

A technology for mass flowmeters and cleaning devices, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc. It can solve problems such as long time consumption, impact on detection accuracy, and inability to meet the cleanliness requirements of mass flowmeters. , to achieve the effect easily obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

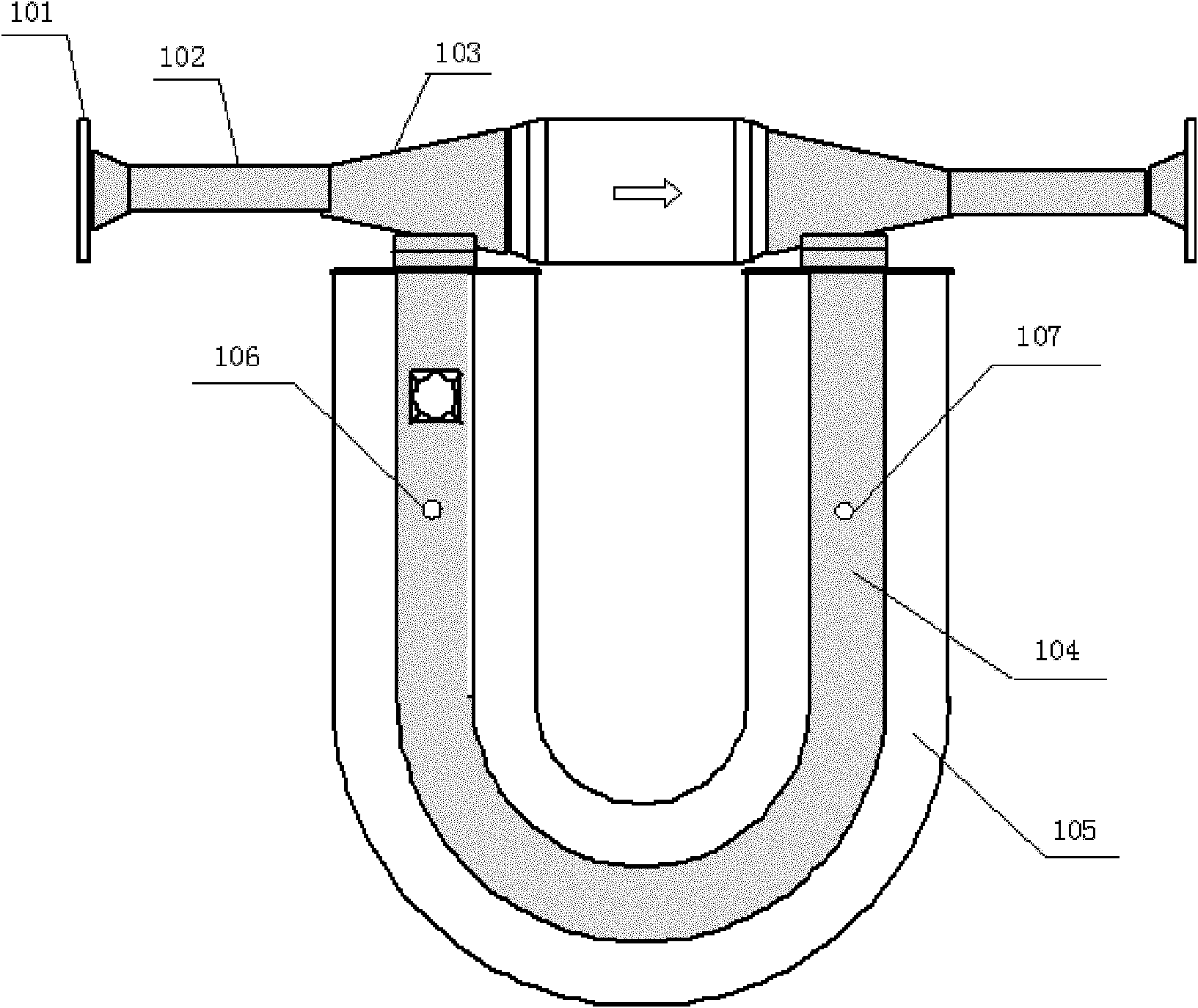

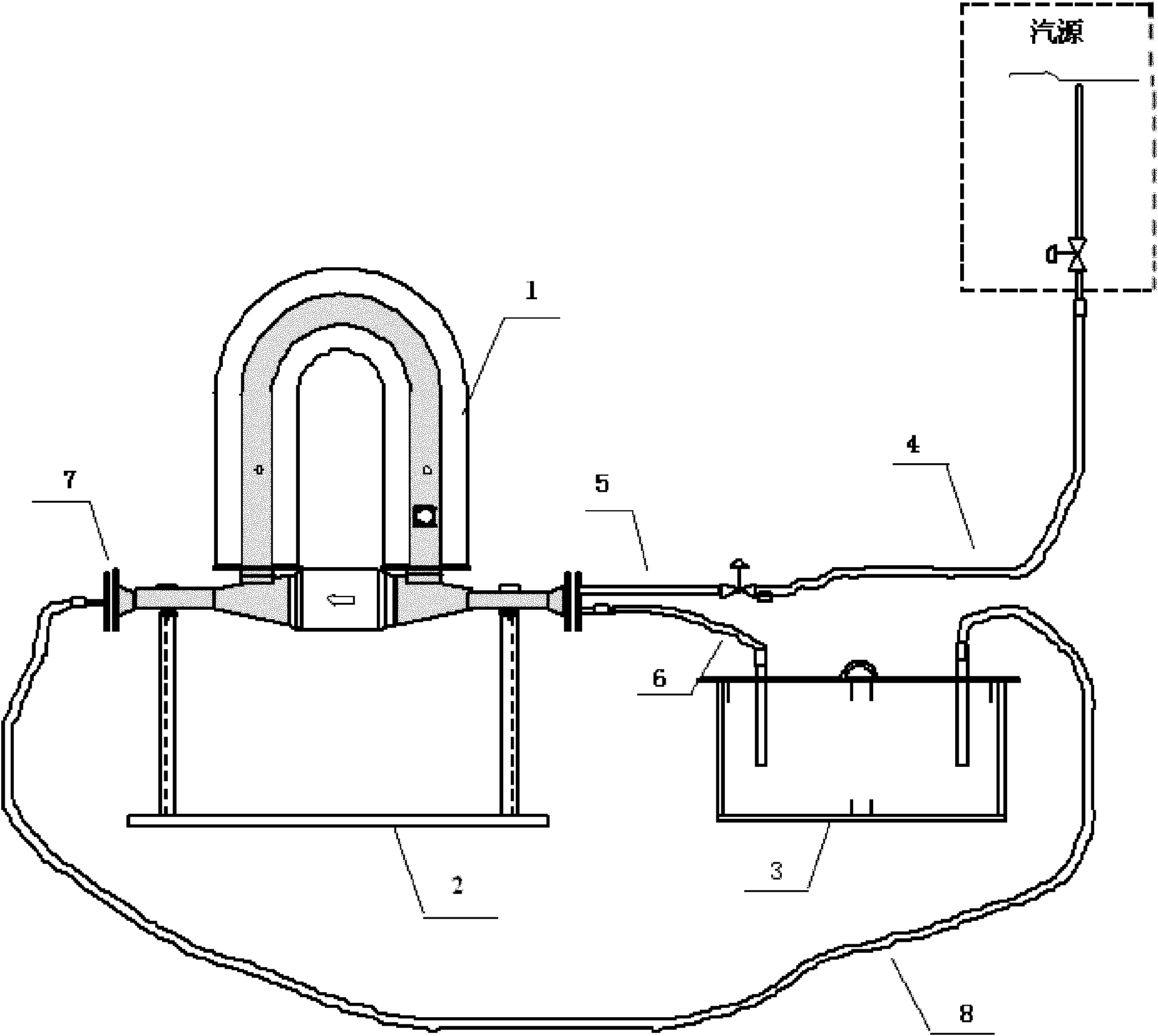

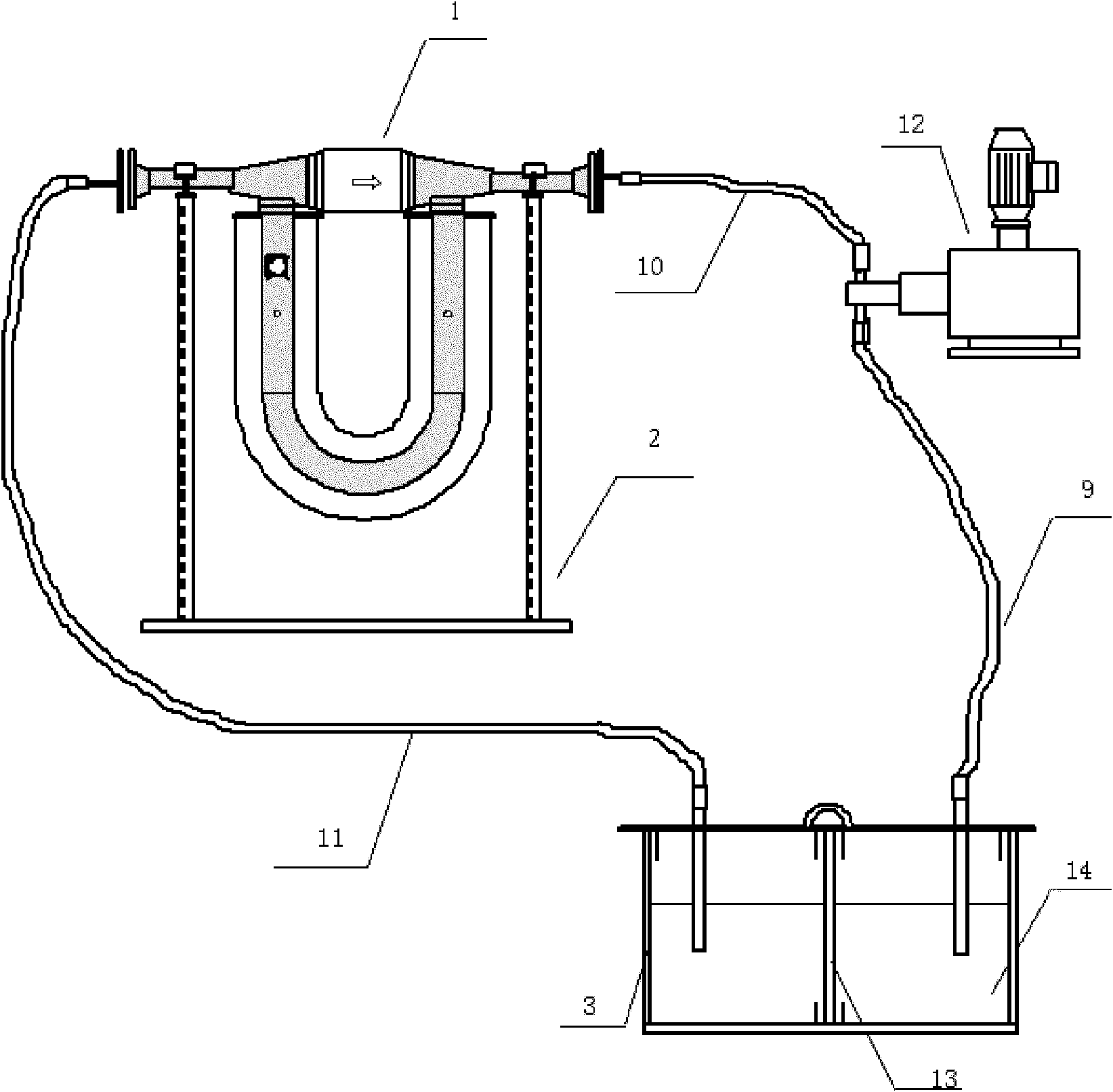

[0045] The mass flowmeter 1 to be dredged in this embodiment is a Coriolis mass flowmeter, the model is CMF400, which is equipped with a preamplifier and a core processor, and has a U-shaped appearance. The dredging unit that present embodiment adopts sees figure 2 , the dredging unit includes a telescopic fixed bracket 2, a cleaning tank 3, a steam purge pipe 4, an inlet purge connector 5, an inlet blowdown pipe 6, an outlet purge connector 7, an outlet blowdown pipe 8 and other components.

[0046] Attached figure 2 Connect the various components. The method of dredging the mass flowmeter 1 is as follows: with the U port of the mass flowmeter 1 facing down, the straight pipe section 102 of the mass flowmeter 1 is connected with the supporting plate 203 and the pipe clip 204 of the telescopic fixed bracket through bolts, and the inlet is blown. The flange pieces of the sweep connector 5 and the outlet purge connector 6 are connected to the flange piece of the mass flow met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com