Building lifter with tractor at bottom

A technology of elevators and traction machines, which is applied in the field of elevator structures, can solve problems such as difficulties, cumbersome installation and debugging, and reduce the area utilization rate of the hoistway, so as to achieve the effects of convenient installation and debugging, increase the area utilization rate, and reduce the cost of building supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

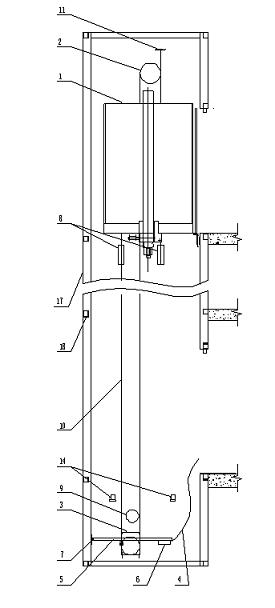

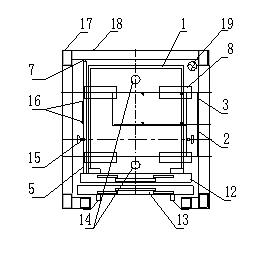

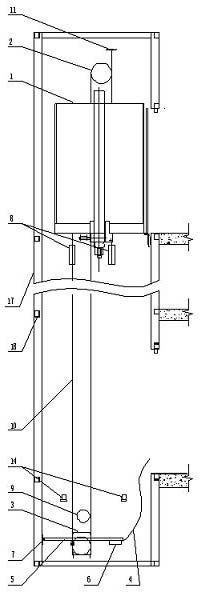

[0013] refer to Figure 1-2 , the construction elevator with the traction machine at the bottom, the outer frame structure of the elevator composed of frame vertical beams 17 and frame beams 18, a cargo compartment 1 is installed in the outer frame structure of the elevator, and guide wheels 2 and rescue ropes 4 are installed on the cargo compartment 1 , bottom wheel 8, traction wire rope 10, door machine 12, landing door device 13, a buffer 14 is installed at the bottom of the elevator outer frame, a guide rail 15, a speed limiter wire rope 16, and a speed limiter are installed in the elevator outer frame The tensioner 9; the traction wheel and the traction machine 3 are installed at the bottom of the outer frame structure of the elevator composed of the frame vertical beam 17 and the frame beam 8, the guide wheel 2 is installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com