Anti-reflective superhydrophilic self-cleaning SiO2 anti-fog coating and preparation method thereof

An anti-fog coating, super-hydrophilic technology, applied in the direction of coating, can solve the problems of high energy consumption, self-cleaning and anti-fog effects, unsatisfactory durability, poor timeliness, etc., to achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

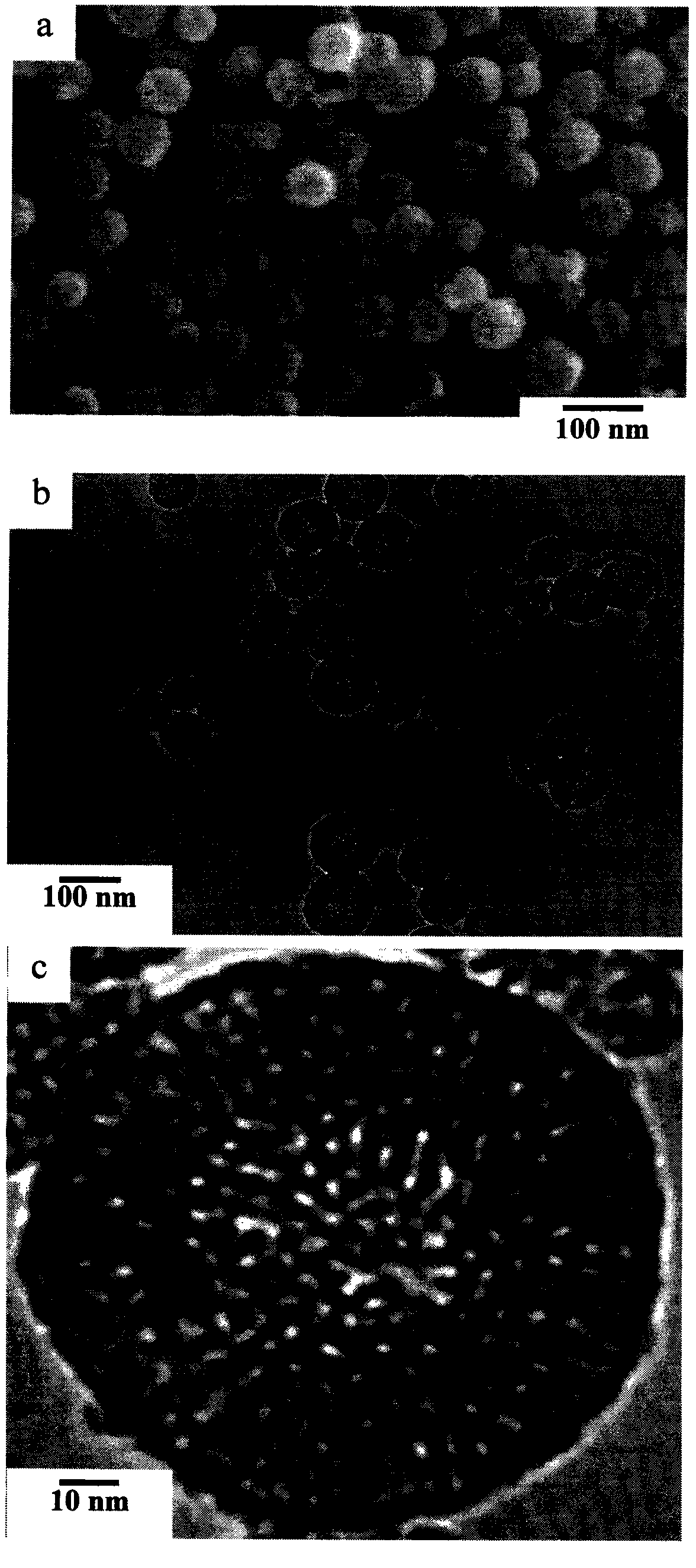

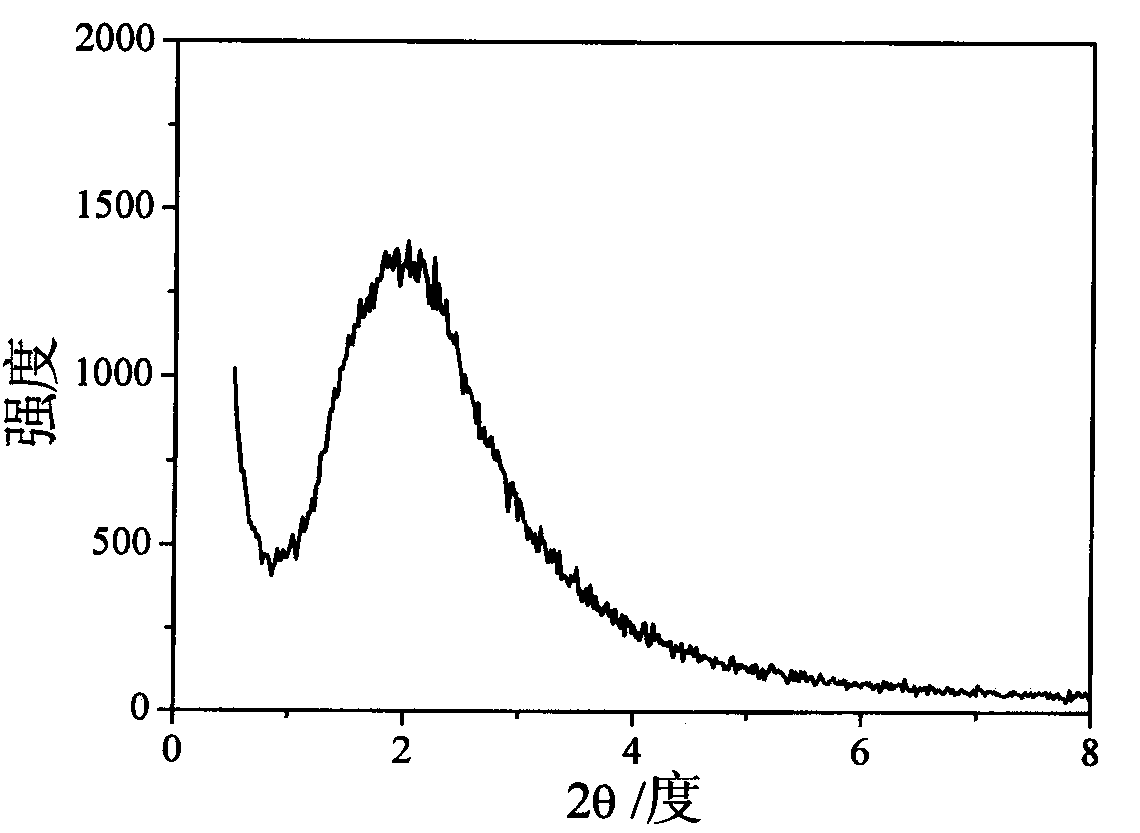

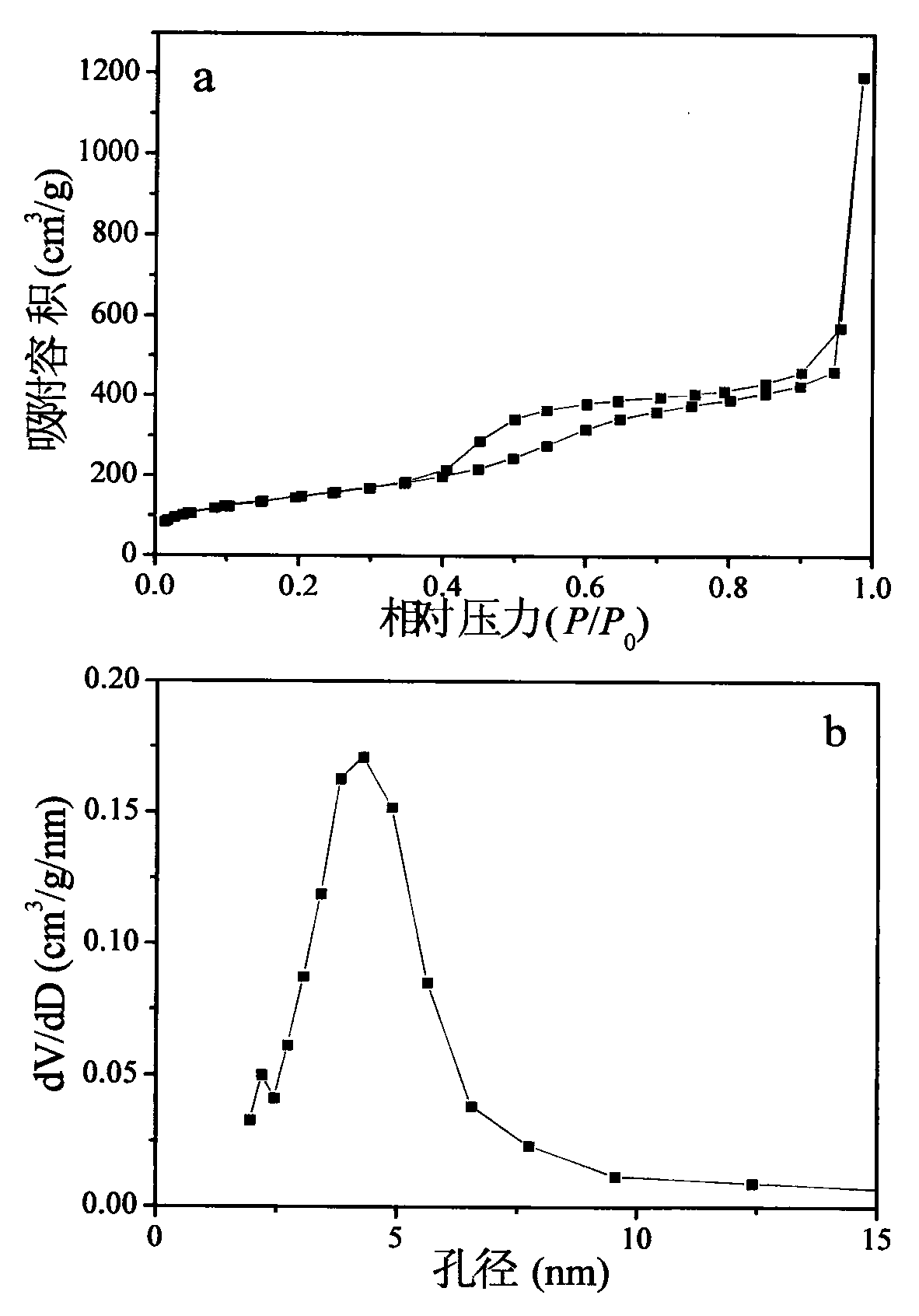

[0051] The shell on the outer surface is thin and non-porous, and the inner shell has mesoporous double-shelled mesoporous SiO 2 Preparation of hollow spheres:

[0052] (1) At 20 to 25 degrees Celsius, 0.1 to 0.3 grams of cetyltrimethylammonium bromide, 90 to 100 milliliters of distilled water (conductivity 18.2 MΩ), and 0.6 to 0.8 milliliters of hydroxide with a concentration of 2 mol / L Sodium solution, 0.04-0.06 ml of dodecyl mercaptan are mixed together, stirred by magnetic force for 10-30 minutes, and the magnetic stirring speed is 500-600 rpm to make it evenly mixed;

[0053] (2) Heat the mixed solution of (1) until the temperature rises to 80 degrees centigrade. Tetraethoxysilane was quickly added, and the final mixture was stirred for 2 hours at 80 degrees Celsius at a magnetic stirring speed of 2000 to 3000 rpm;

[0054] (3) filtering the solid precipitate obtained by the reaction in step (2), washing with water, and drying in an oven at a temperature of 60 to 80 deg...

Embodiment 2

[0063] The outer surface of the shell is thin and non-porous, and the inner shell has mesoporous double-shelled mesoporous SiO 2 Superhydrophilic and antireflection self-cleaning SiO with rough structure on the surface of hollow spheres 2 Preparation of anti-fog coating: Utilize the mesoporous SiO prepared in Example 1 with a mass percent content of 0.2 to 0.6% on the outer surface, which is thin and non-porous, and has a mesoporous double shell on the inner shell 2 The suspension of hollow spheres is used as raw material, and its preparation method comprises the following steps:

[0064] (1) the glass piece is immersed in the newly prepared Pirhana solution (mass concentration is about 98% H 2 SO 4 solution with a mass concentration of approximately 30% H 2 o 2 The mixture of solutions, where, H 2 SO 4 solution with H 2 o 2 The volume ratio of the solution is 7: 3), after soaking for 5 to 20 minutes, take out and wash with distilled water, and dry with nitrogen to obt...

Embodiment 3

[0070] The two outer shells are thin and non-porous, and the inner shell has mesoporous double-shelled mesoporous SiO 2 Superhydrophilic and anti-reflection self-cleaning SiO with rough structure on the surface of hollow spherical particles 2 Preparation of anti-fog coating: Utilize the mesoporous SiO prepared in Example 1 with a mass percent content of 0.2 to 0.6% on the outer surface, which is thin and non-porous, and has a mesoporous double shell on the inner shell 2 Hollow sphere suspension is as raw material, and its preparation method comprises the following steps:

[0071] (1) the glass piece is immersed in the newly prepared Pirhana solution (mass concentration is about 98% H 2 SO 4 solution with a mass concentration of approximately 30% H 2 o 2 The mixture of solutions, where, H 2 SO 4 solution with H 2 o 2 The volume ratio of the solution is 7: 3), after soaking for 5 to 20 minutes, take out and wash with distilled water, and dry with nitrogen to obtain a cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com