Preparation method of transmission electron microscope (TEM) sample

A sample and sample technology, applied in the field of TEM sample preparation, can solve the problems of no way to use TEM, damage in the thickness direction, amorphization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

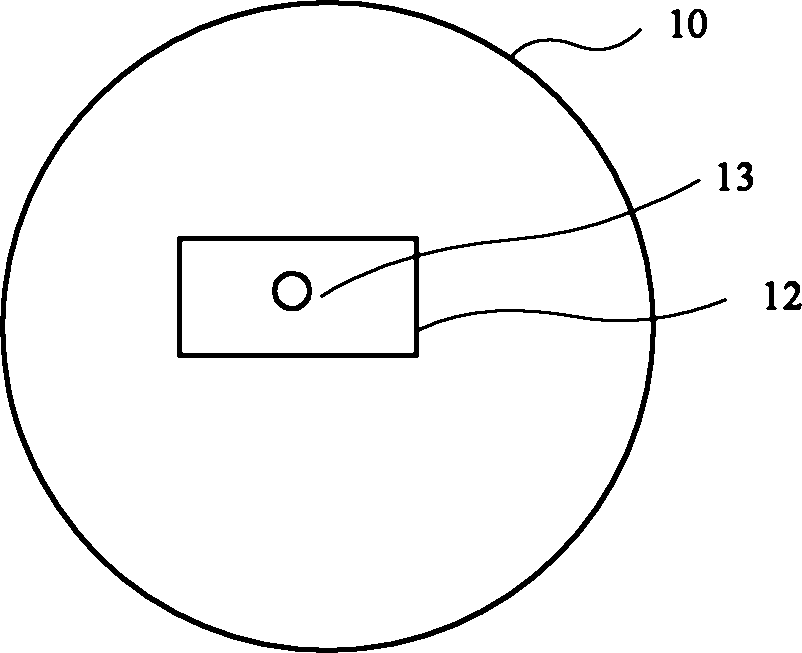

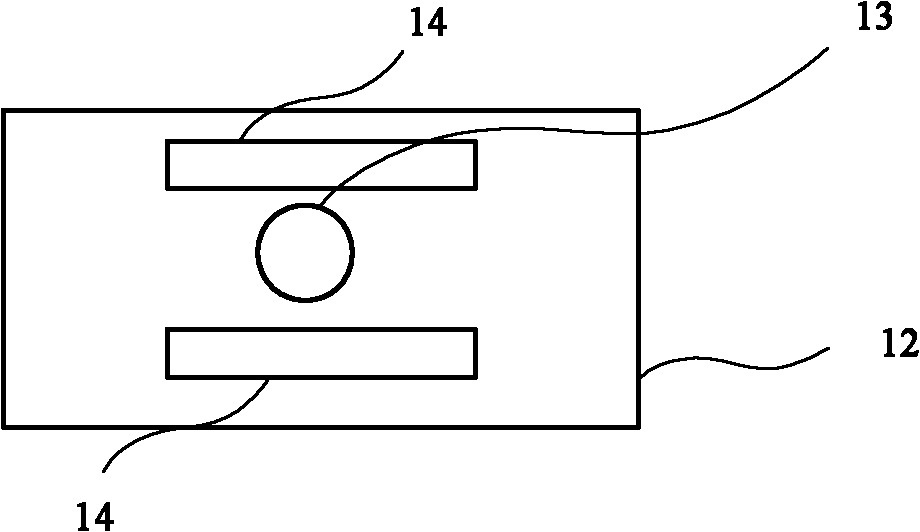

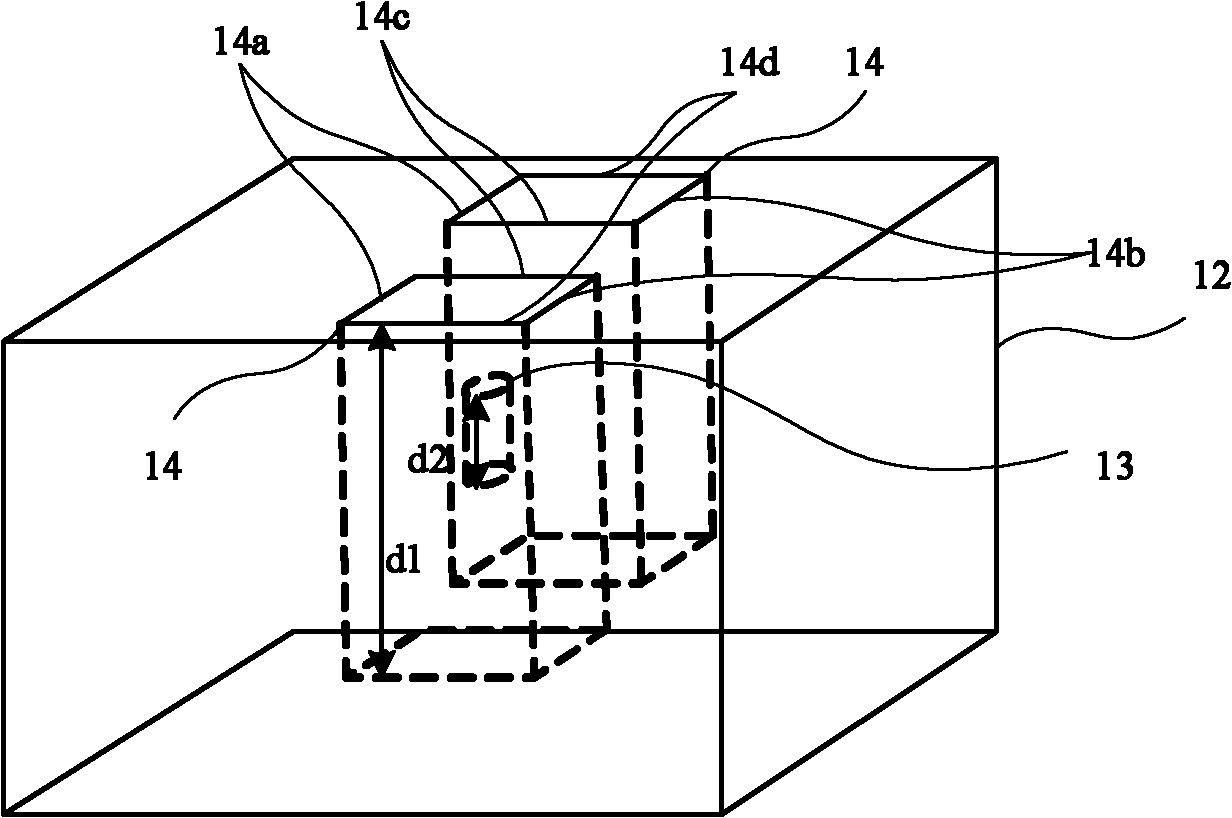

preparation example Construction

[0034] Figure 5 It is a flowchart of the preparation method of the TEM sample of the present invention. Such as Figure 5 Shown, the preparation method of TEM sample of the present invention comprises steps:

[0035] S10, providing a detection sample, the detection sample has a pattern to be detected;

[0036] S20, cutting out a sample from the test sample, the sample including a pattern to be detected;

[0037] S30, thinning the sample from two opposite cutting surfaces of the sample, and sticking a fixing ring on one of the thinned cutting surfaces;

[0038] S50, clamping the fixing ring, using Ga ion beams to bombard the regions on both sides of the pattern to be detected on the side of the sample having the device layer, so as to form pits on both sides of the pattern to be detected;

[0039] S60, clamping the fixing ring, bombarding the thinned cutting surface with an Ar ion beam, and continuing to thin the area where the pattern to be detected is located.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com