Method for adjusting chip graph density using redundancy graph insertion,

A technology of graphic density and redundant graphics, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of disregarding the graphic density value, high graphic density, and low graphic density, so as to avoid insufficient graphic density. Uniformity problem, effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

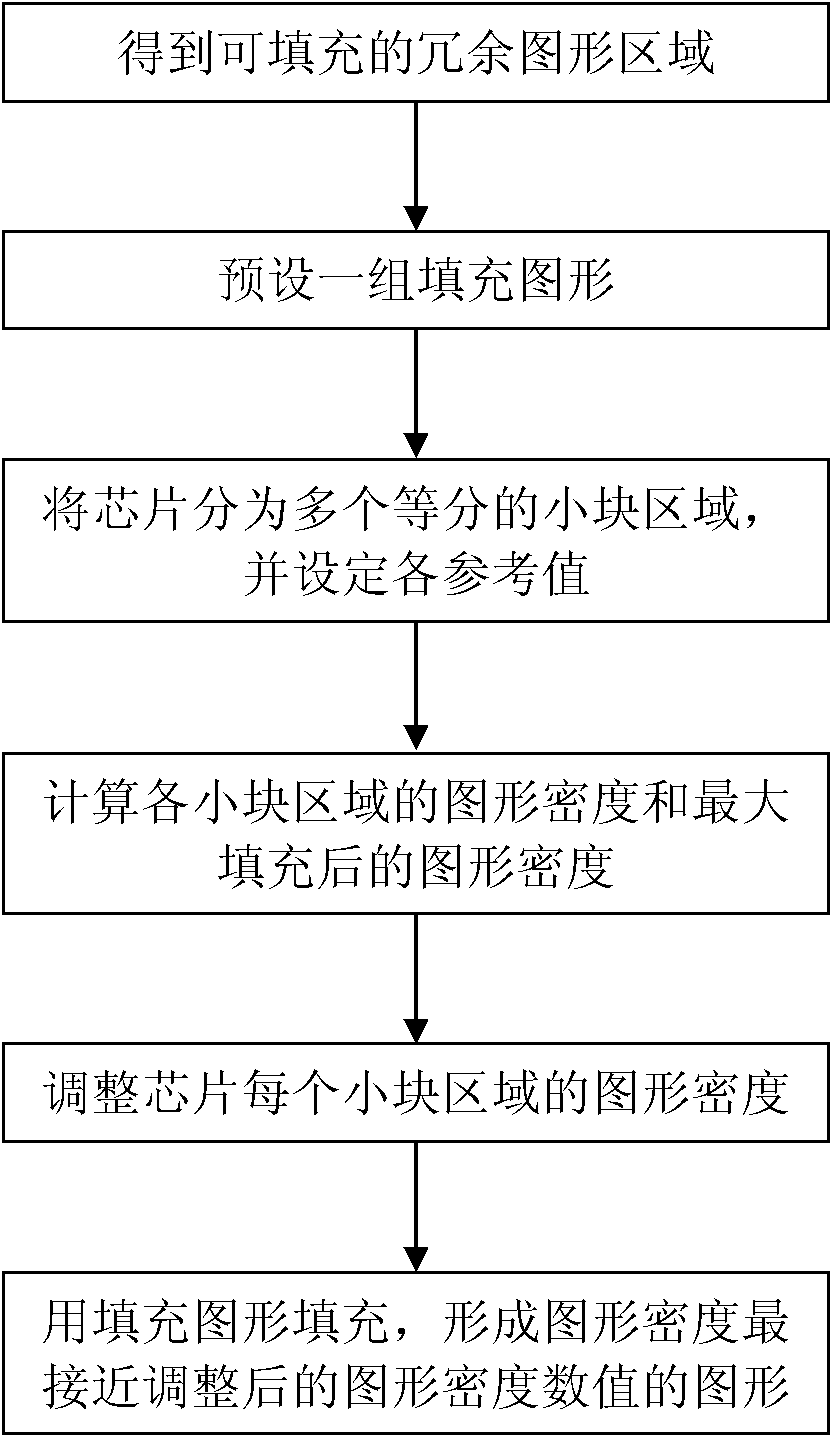

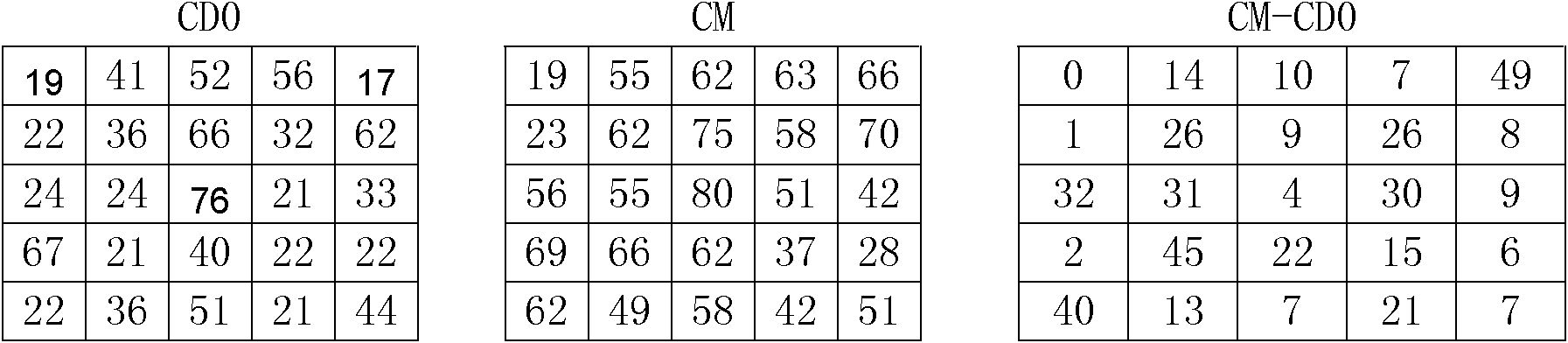

[0018] The method of the present invention is to design a filling pattern scheme with a predetermined pattern density for the layer that is about to carry out a CMP process or an etching process, then copy and make this design into the current layer, and then perform a CMP process or etching craft. The method for adjusting chip pattern density by utilizing redundant pattern filling of the present invention comprises the following steps (see figure 2 ):

[0019] (1) According to the filling rules, the fillable area of a certain layer in the chip preparation (that is, the layer that needs to be filled with redundant graphics, such as the polysilicon layer) is obtained. Because the insertion of redundant graphics may affect the electrical performance of the chip, the fillable area is not equal to the blank area of the current layer, and is usually smaller than the blank area of the current layer. The filling rule is that the insertion of the filling pattern cannot affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com