Battery cooling structure

A cooling structure and storage battery technology, applied in the combination of power plant cooling layout, secondary battery, battery temperature control, etc., can solve the problems of the cooling effect of the third battery module, such as decreased cooling effect, and achieve improved cooling effect and large heat transfer area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

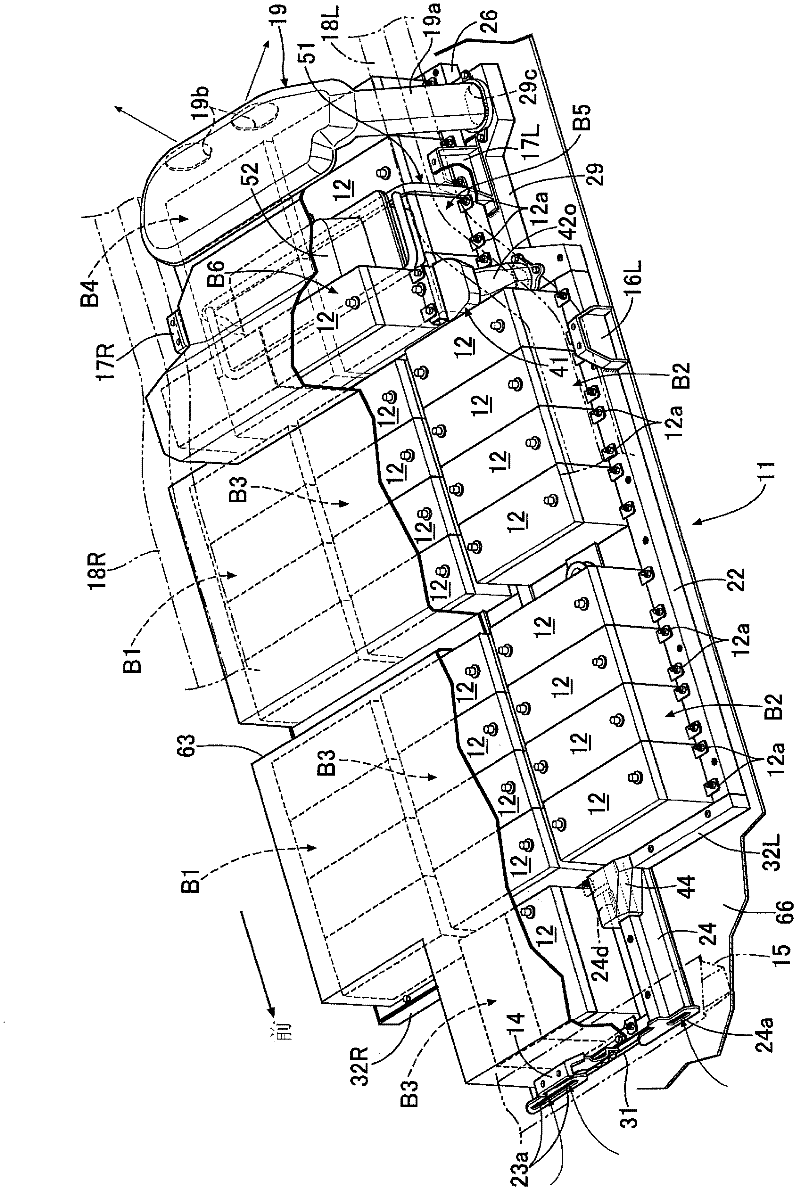

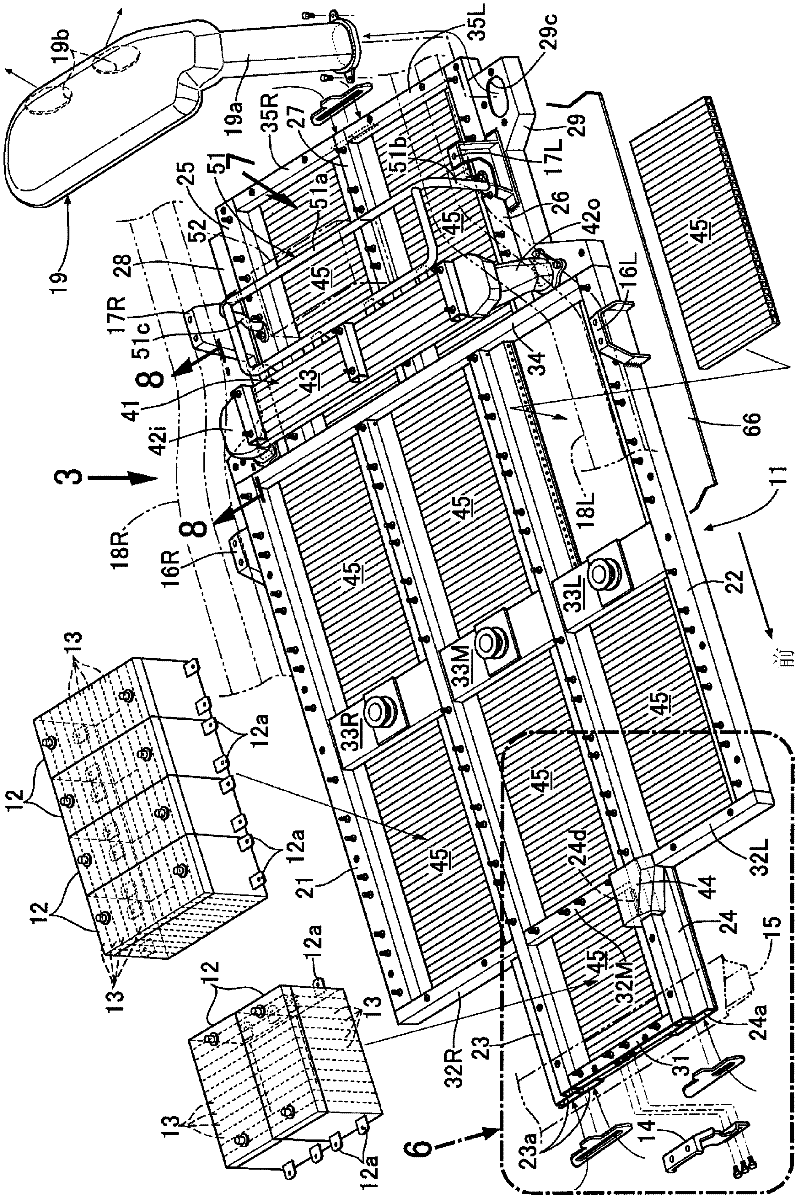

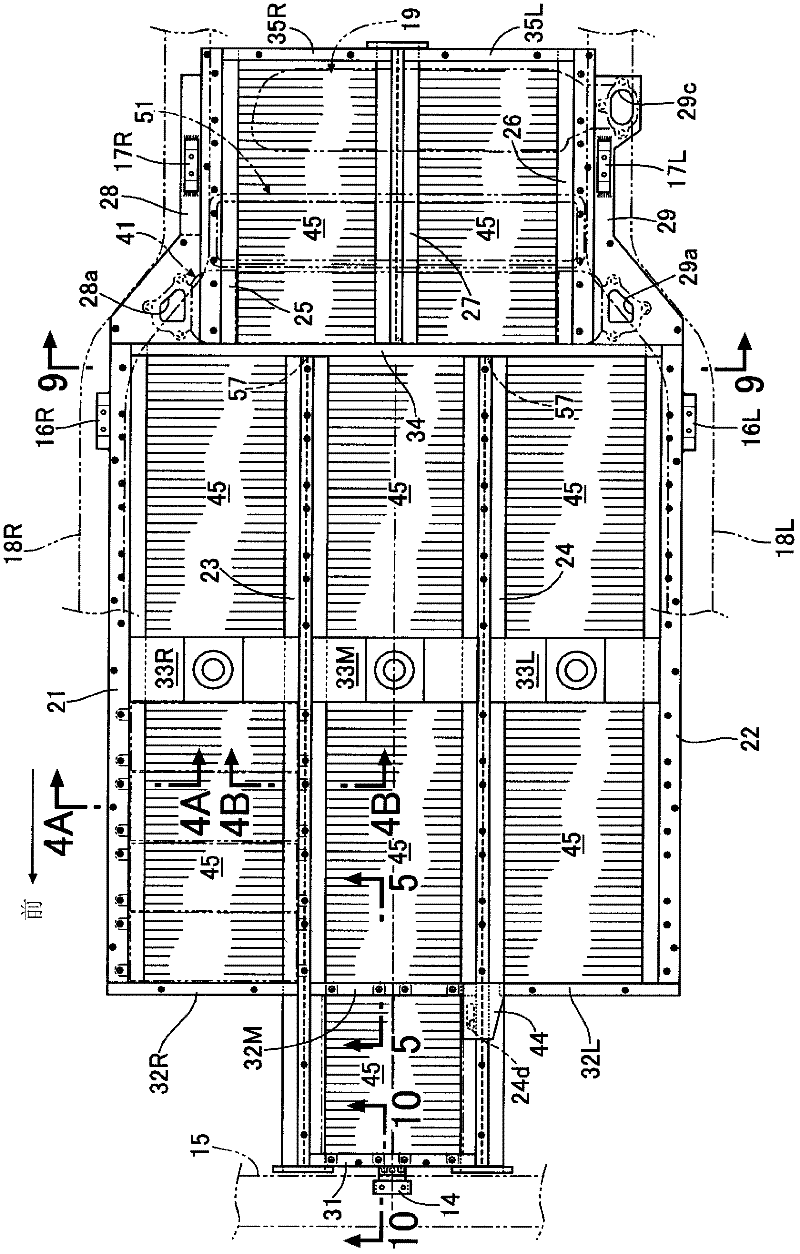

[0038] Below, based on Figure 1 to Figure 13 , to describe the embodiment of the present invention.

[0039] Such as Figure 1 ~ Figure 3 As shown, a battery unit for supplying electric power to a motor generator serving as a driving power source of an electric vehicle includes a flat disk 11 and a plurality of battery modules 12 . . . placed on the surface of the disk 11 . Each battery module 12 has a rectangular parallelepiped shape, and accommodates a plurality of battery cells 13 electrically connected in series inside it (refer to figure 2 ). Two brackets 12 a , 12 a for fixing the battery module 12 to the tray 11 protrude from both ends in the longitudinal direction of the battery module 12 .

[0040] The mounting bracket 14 provided at the front of the panel 11 is combined with the cross member 15 of the vehicle body, and the two mounting brackets 16L, 17L provided at the left rear of the panel 11 are combined with the left side frame 18L. Two mounting brackets 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com