Spike heating transmission gear

A transmission device and road stud technology, applied to lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of low product quality stability, low heating efficiency, large floor space, etc., and achieve good results and convenience The effect of heating and working intensity is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

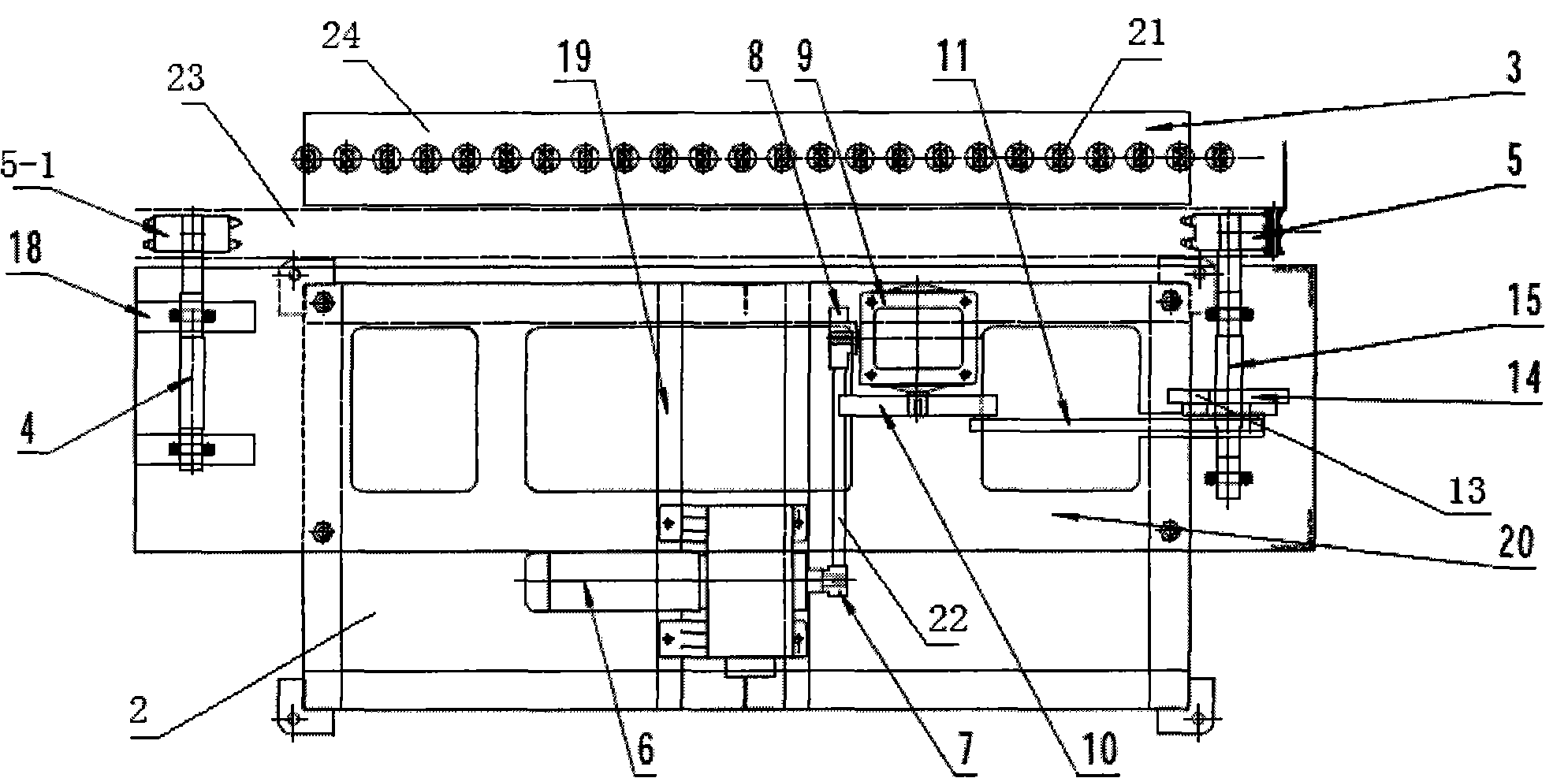

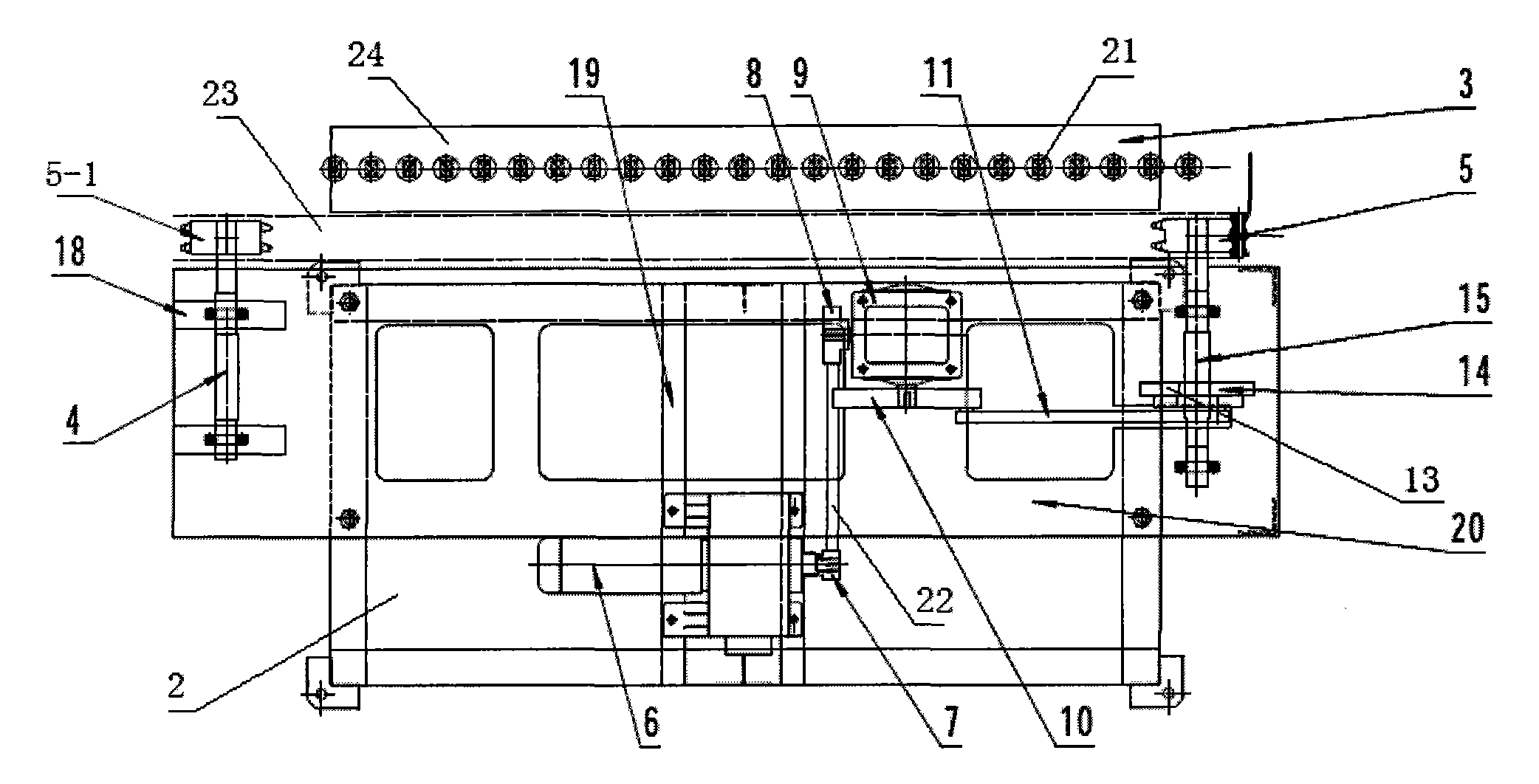

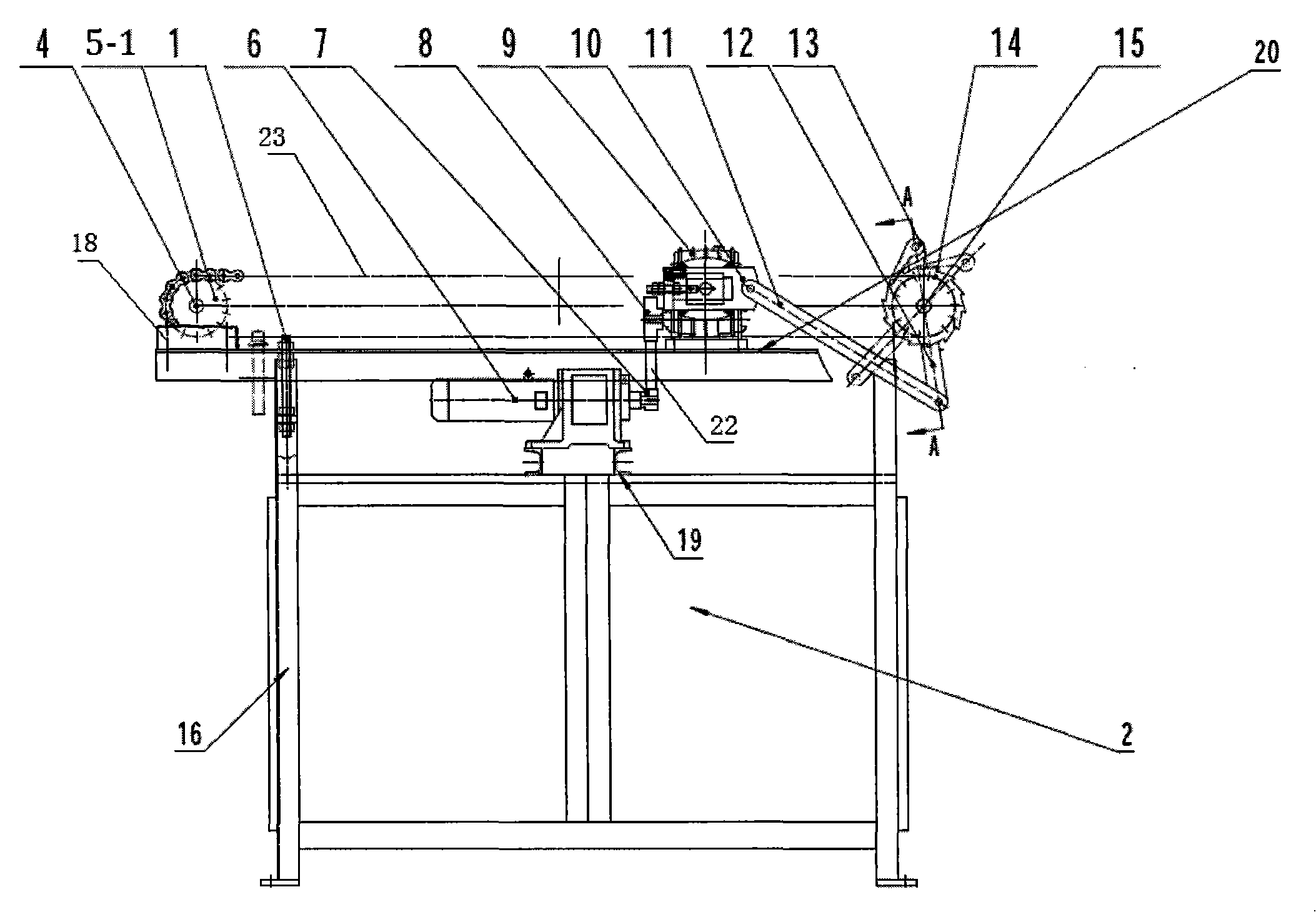

[0016] Embodiment 1: As shown in Figures 1 to 3, this embodiment consists of an electrical cabinet 2, an inductor 3, a motor 6, a reducer 9, a connecting rod 11, a rocker 12, a ratchet 14, a pawl 13, a driving shaft 15, Chain 23, driven shaft 4, driving sprocket 5, driven sprocket 5-1 and clamping plate 24 are formed, and electric cabinet 2 is the supporting component of this device. The electrical cabinet 2 is provided with a support foot 16, a channel steel 19, a bearing seat 18, a load-bearing tripod 17 and a cover plate 20. A height adjusting bolt 1 is arranged in the support foot 16 . The height adjusting bolt 1 is arranged under the cover plate 20 .

[0017] The inductor 3 is arranged on the load-bearing tripod 17 , the driven shaft 4 is installed on the bearing seat 18 , the motor 6 is bolted to the channel steel 19 , and the reducer 9 is arranged on the cover plate 20 . The large pulley 8 on the reducer 9 is connected to the small pulley 7 on the motor 6 through a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com