Method for applying single-supply error amplifier to negative high voltage power control circuit

A technology of error amplifier and negative high-voltage power supply, which is applied to control/regulation systems, conversion equipment and instruments without intermediate conversion to AC, and can solve the problems of complex peripheral circuits of error amplifiers, achieving good real-time performance, fewer components, The effect of high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

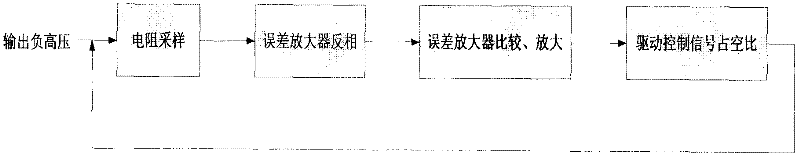

[0011] The specific implementation steps of the application method of the single power supply error amplifier in the negative high voltage power supply control circuit of the present invention can be found in figure 1 :

[0012] ① Perform resistance sampling on the output negative high voltage and convert it into a negative low voltage signal;

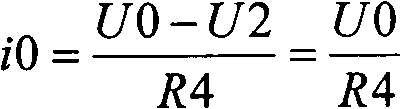

[0013] ②The single-supply error amplifier inverts the negative low-voltage signal to generate a positive voltage feedback signal with the same amplitude;

[0014] ③ The positive voltage feedback signal and the reference voltage are compared and amplified by the single-supply error amplifier to generate an error signal;

[0015] ④ Use the error signal to change the duty ratio of the drive control signal to achieve the purpose of adjusting the negative high voltage output.

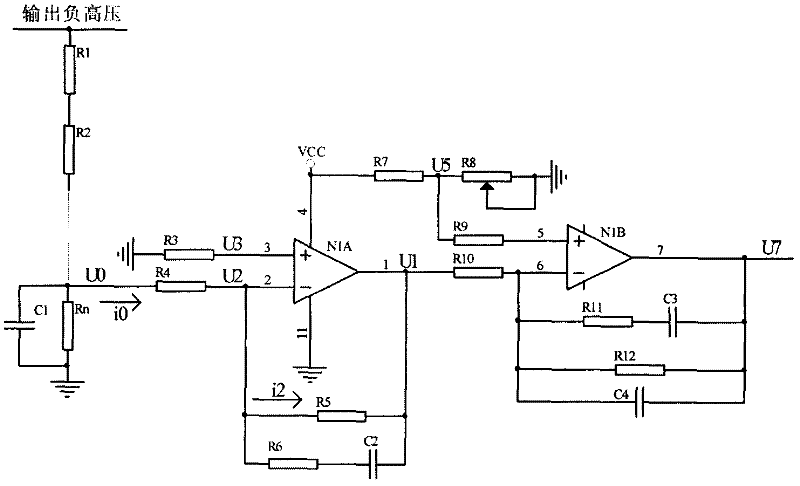

[0016] The circuit schematic diagram of the application method of the single power supply error amplifier in the negative high voltage power supply control circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com