Process for the oxidative coupling of methane

A technology of oxidative coupling and methane, applied in chemical instruments and methods, catalysts, organic chemistry, etc., can solve problems such as reducing the production cost of ethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B

[0045] Oxidation catalysts comprising an oxide substrate (MgO) promoted with Sr and La were prepared. A Sr / La / MgO catalyst was used for the oxidative coupling of methane. The catalyst contained 5% by weight Sr [from strontium nitrate (3.62 g)] and 5% by weight La [from lanthanum oxide (3.51 g)]. 3 ) 2 Salt, La 2 o 3 (Sigma-Aldrich, 98.0%) and MgO (22.85 g) (Fisher, 99%) were prepared in aqueous solution. The resulting mixture was dried at 120°C for 3 hours and then calcined in air at 850°C for 1 hour. The catalyst was ground and sieved to a size of 20-40 mesh, 0.855 g of the catalyst was loaded into a quartz reactor, and the catalyst bed was fixed with a quartz tampon and quartz debris. As a form of catalyst pretreatment, the reactor was heated to 850° C. in air at 100 ml / min for 2 hours. The reactor was then cooled to 600 °C in helium in preparation for the OCM experiment.

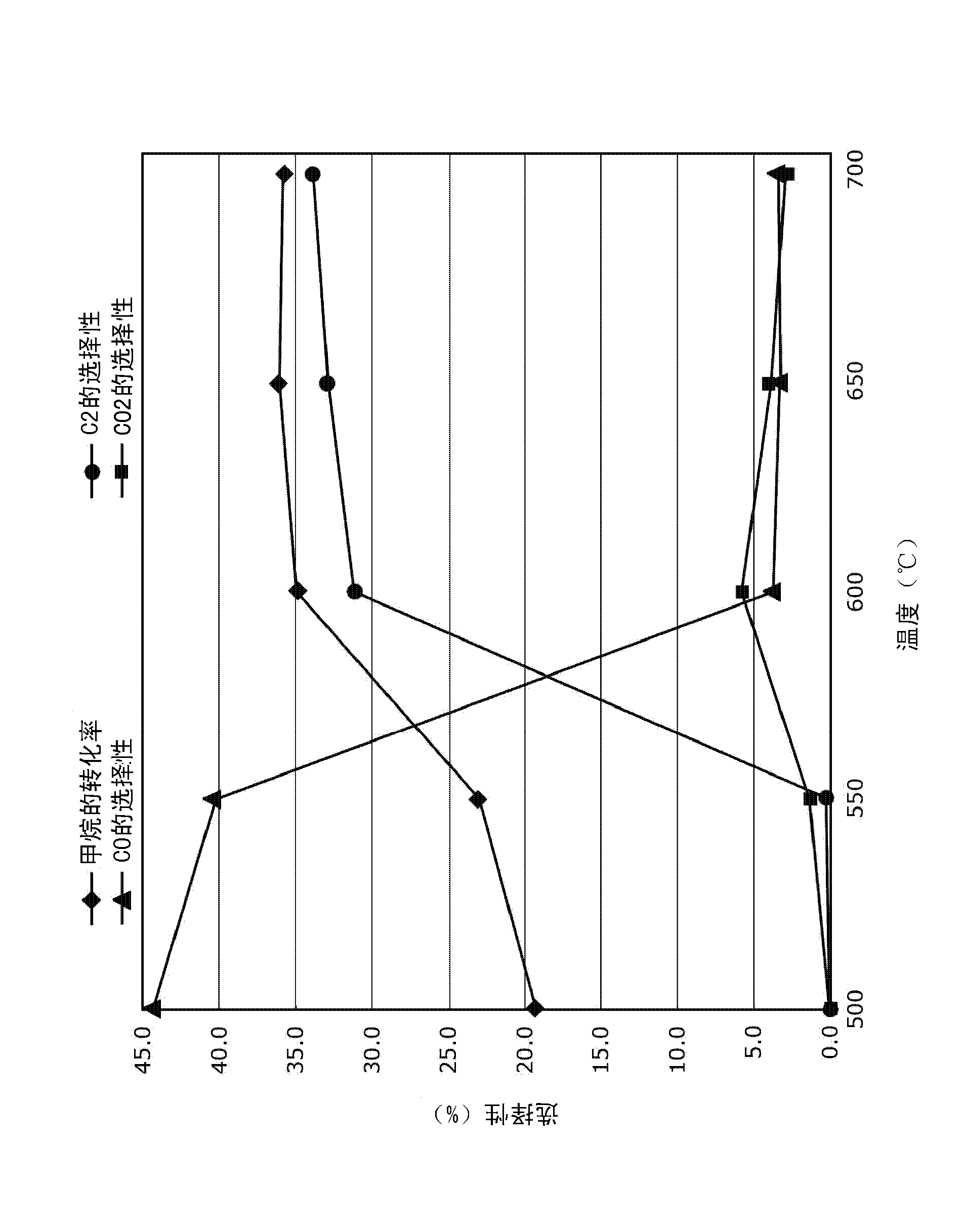

[0046] Five OCM experiments were carried out with the catalyst Sr / La / MgO. The five trials corr...

Embodiment C

[0052] Oxidation catalysts containing MgO substrates and promoted with Na, Cs and Re were prepared. Na / Cs / Re / MgO catalysts were used for the oxidative coupling of methane. The catalyst contained 5% by weight Na (3.811 grams of sodium chloride), 5% by weight of Cs (2.199 grams of cesium nitrate), and 0.01% by weight of Re (0.5856 grams of rhenium chloride) and MgO (23.4033 grams) (Fischer Seoul company, 99%), prepared in aqueous solution by incipient wetness impregnation. The resulting mixture was dried at 120°C for 3 hours and then calcined in air at 850°C for 1 hour. The catalyst was ground and sieved to a 20-40 mesh size (420-841 microns), 0.597 g of the catalyst was loaded into a quartz reactor, and the catalyst bed was fixed with quartz wool plugs and quartz chips. To pretreat the catalyst, the reactor was heated to 850°C for 2 hours in 100 ml / min of air. The reactor was then cooled to 600 °C in helium in preparation for OCM and OMT experiments.

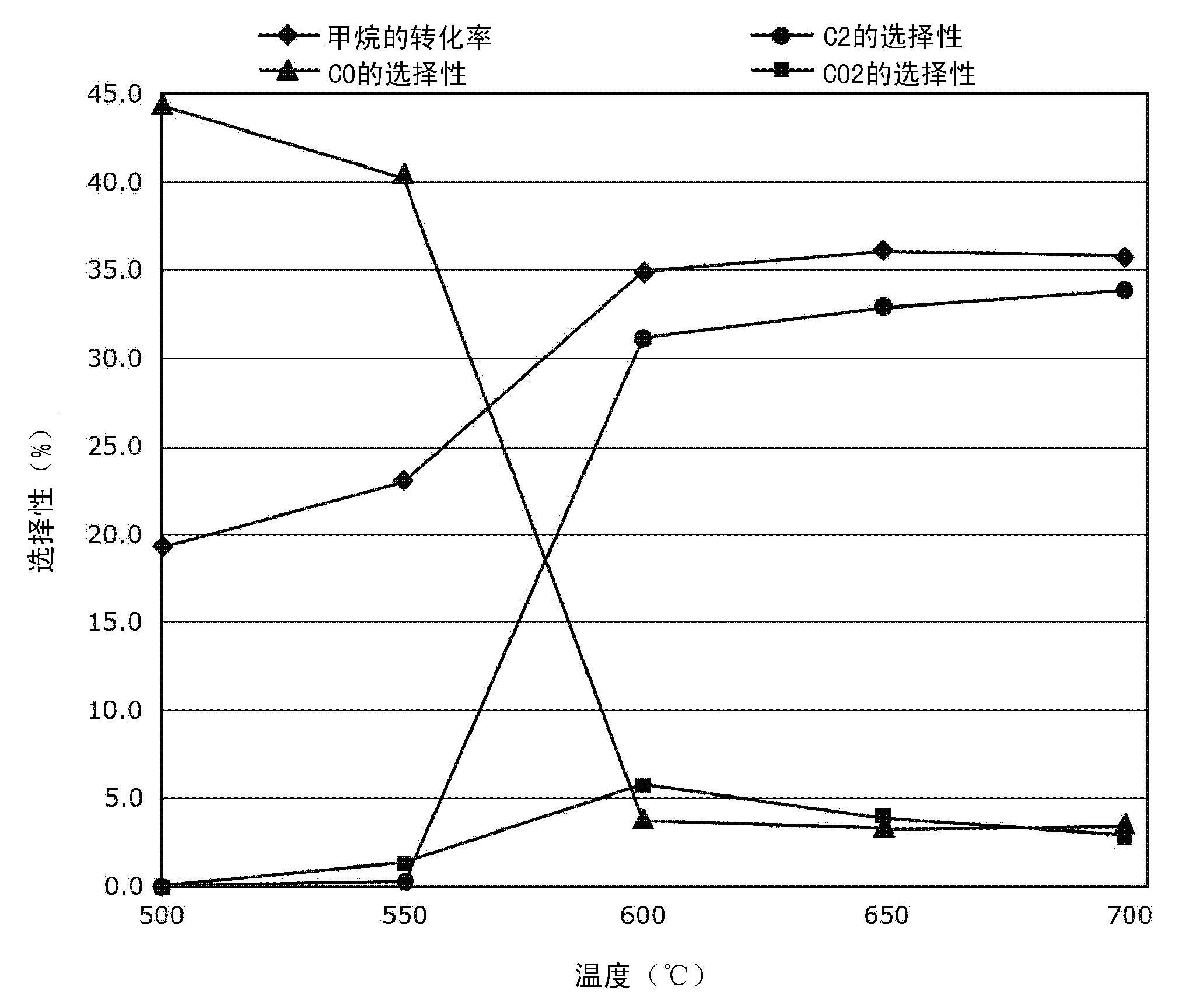

[0053] Four OCM exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com