Antistatic resin composition

A resin composition, anti-static technology, used in transportation and packaging, other chemical processes, thin material processing, etc., can solve the problems of loss of anti-static effect, rough surface, and reduced impact resistance, and achieve excellent permanent anti-static performance. , excellent appearance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

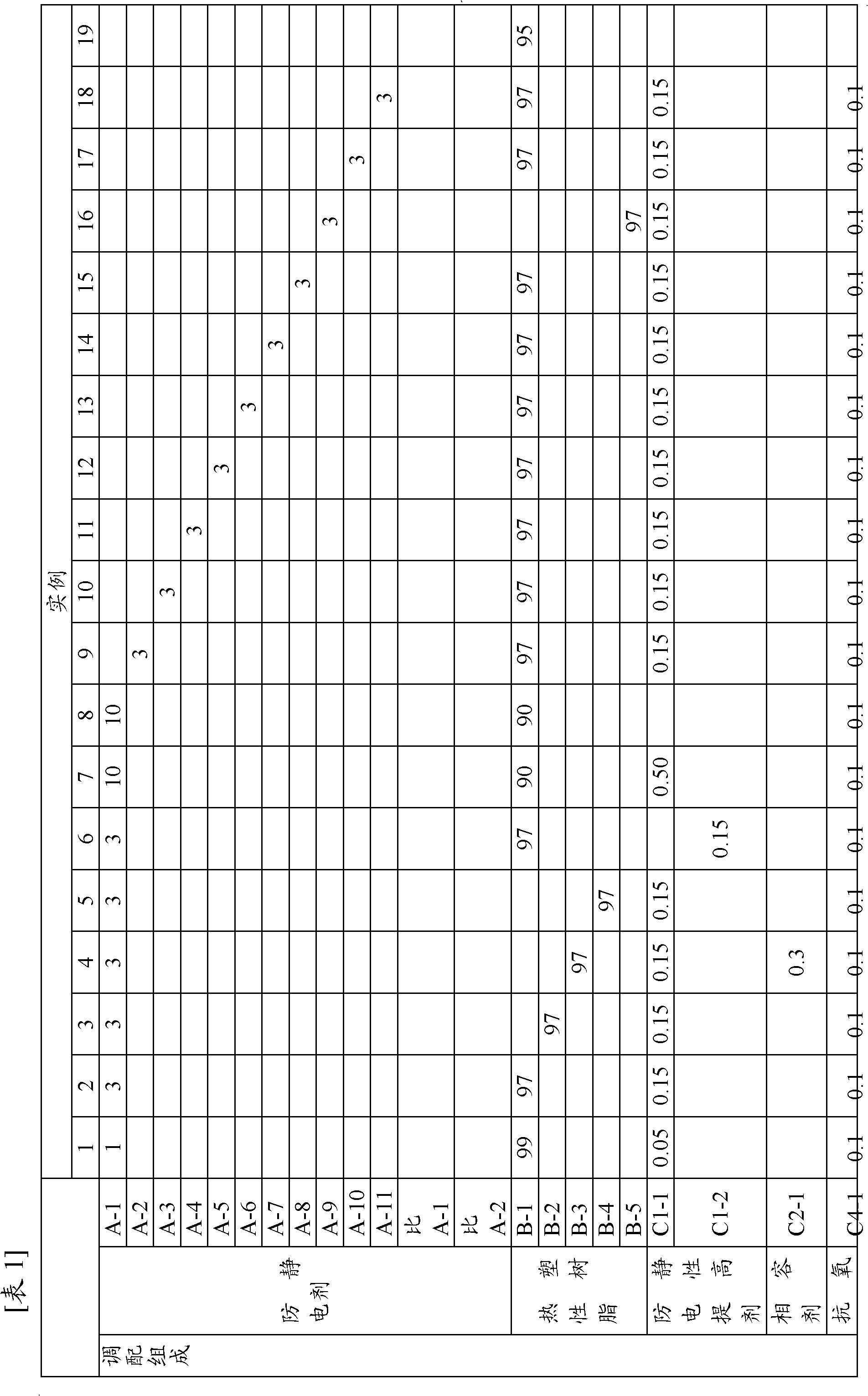

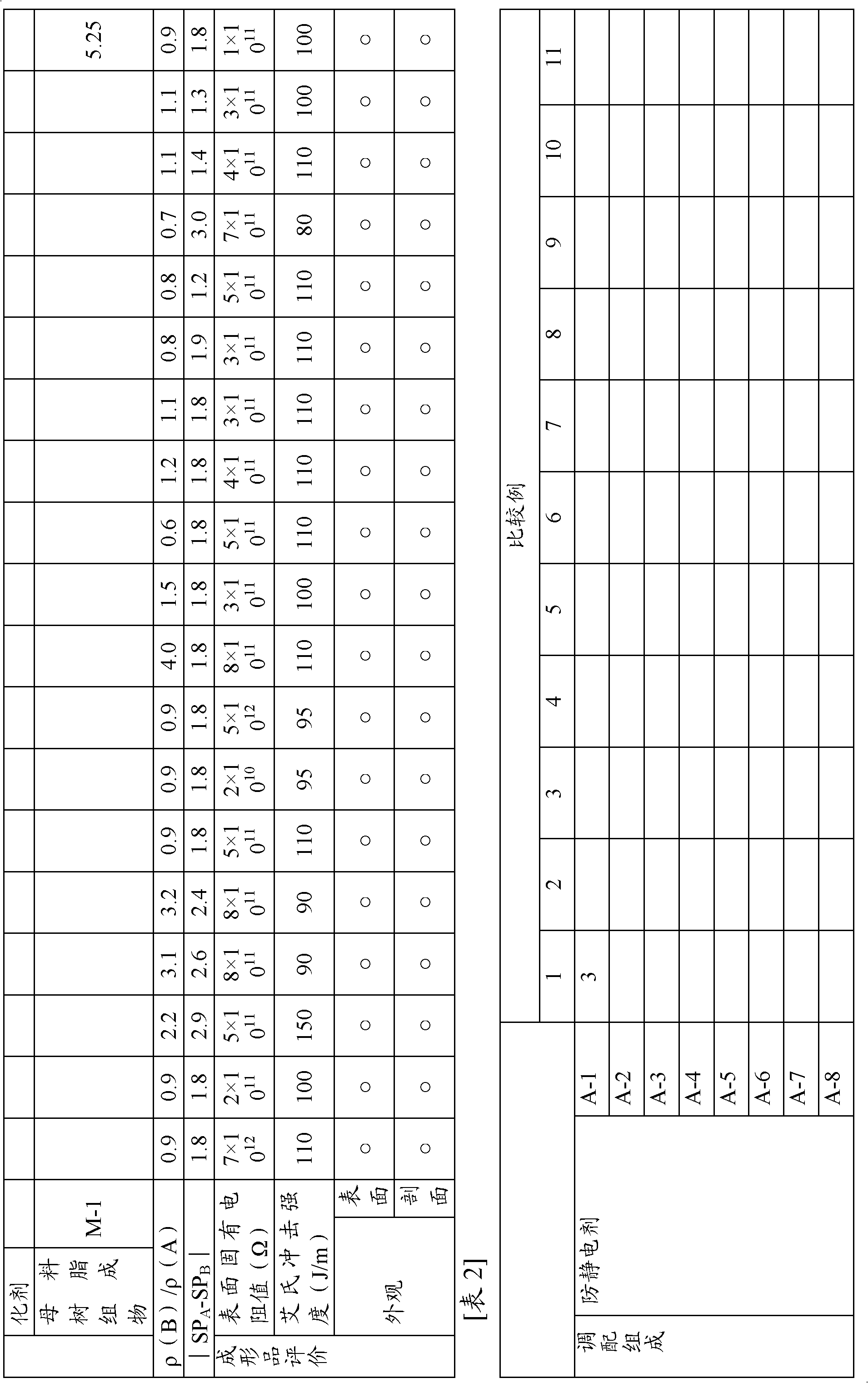

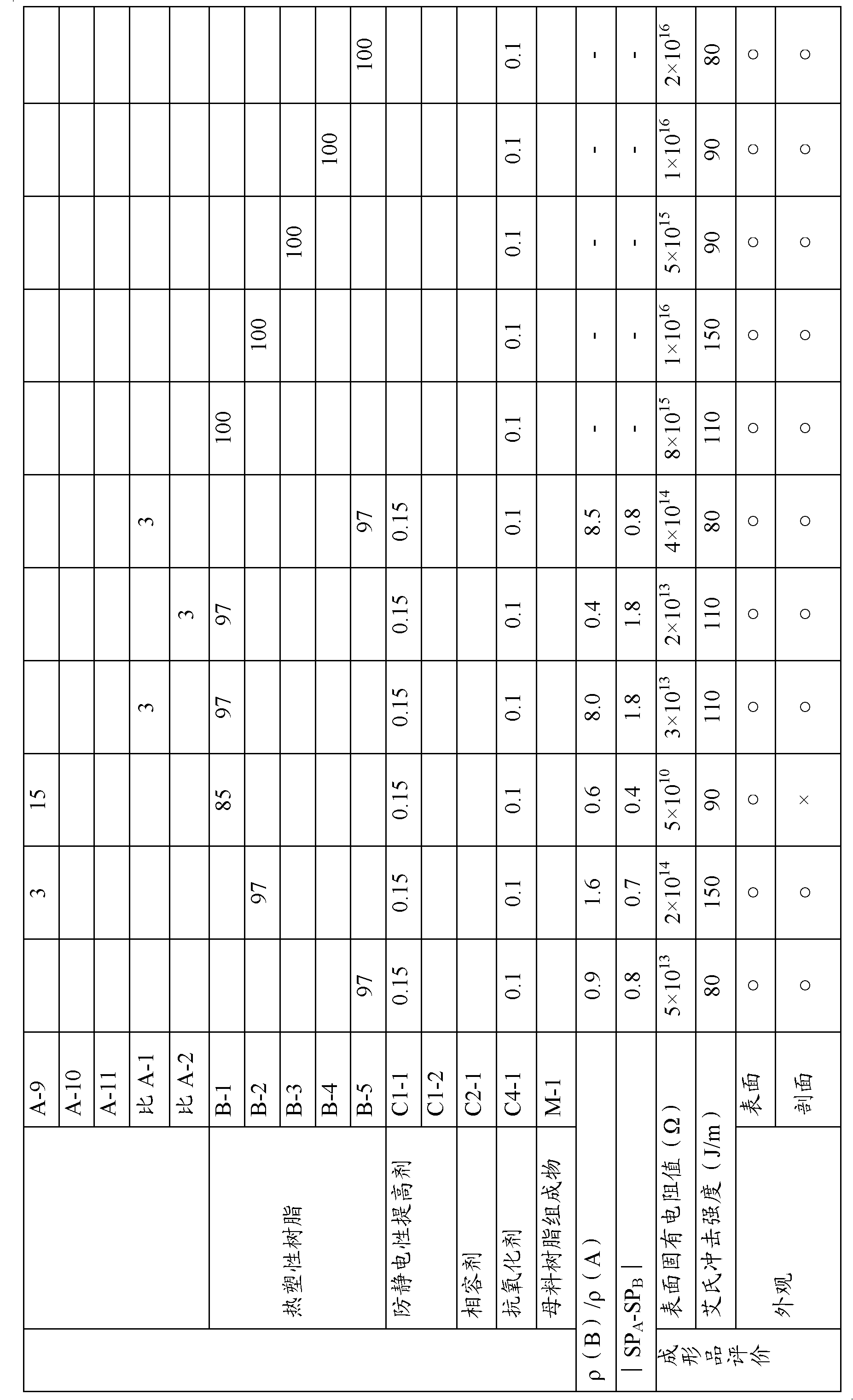

Examples

manufacture example 1

[0335] Production example 1 [production of acid-modified polyolefin (b1-1)]

[0336] In a stainless steel autoclave, add 95 parts of the thermal degradation method [the density at 23°C is 0.90g / cm 3 , MFR is 6.0g / 10min ethylene / propylene (random addition) copolymer (ethylene content is 2%) carry out thermal degradation under 410 ± 0.1 ℃, nitrogen environment] obtained low molecular weight ethylene / propylene random copolymerization material (Mn is 3,500, density is 0.89g / cm 3 , the amount of double bonds per 1,000 C is 7.1, the average number of double bonds per molecule is 1.8, and the content of polyolefin that can be modified at both ends is 90%), 10 parts of maleic anhydride, 30 Parts of xylene were melted at 200° C. under a nitrogen atmosphere (closed), and reacted at 200° C. for 20 hours.

[0337] Then, excess maleic anhydride and xylene were distilled off under reduced pressure at 200° C. for 3 hours to obtain an acid-modified polyolefin (b1-1). (b1-1) had an acid val...

manufacture example 2 2

[0338] Production example 2 [production of secondary modified polyolefin (b1-2)]

[0339] In a stainless steel autoclave, add 88 parts of (b1-1) and 12 parts of 12-aminododecanoic acid, melt it at 200°C under a nitrogen atmosphere, and heat it at 200°C for 3 hours at 1.3 The reaction is carried out under a reduced pressure of kPa or less to obtain a secondary modified polyolefin (b1-2). (b1-2) had an acid value of 24.0 and Mn of 4,200.

manufacture example 3

[0340] Production Example 3 [Production of modified polyolefin (b1-3) having hydroxyl groups at both ends of the polymer]

[0341] In a stainless steel autoclave, 95 parts of acid-modified polyolefin (b1-1) and 5 parts of ethanolamine were melted at 180° C. under a nitrogen atmosphere, and reacted at 180° C. for 2 hours. Then, excess ethanolamine was distilled off under reduced pressure at 180° C. for 2 hours to obtain a modified polyolefin (b1-3) having hydroxyl groups at both ends of the polymer. (b1-3) had a hydroxyl value of 26.0, an amine value of 0.01, and Mn of 3,900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com