Film-forming apparatus

A film-forming device and magnetic field technology, applied in ion implantation plating, coating, electrical components, etc., can solve the problems of substrate surface temperature rise, substrate damage, substrate quality degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

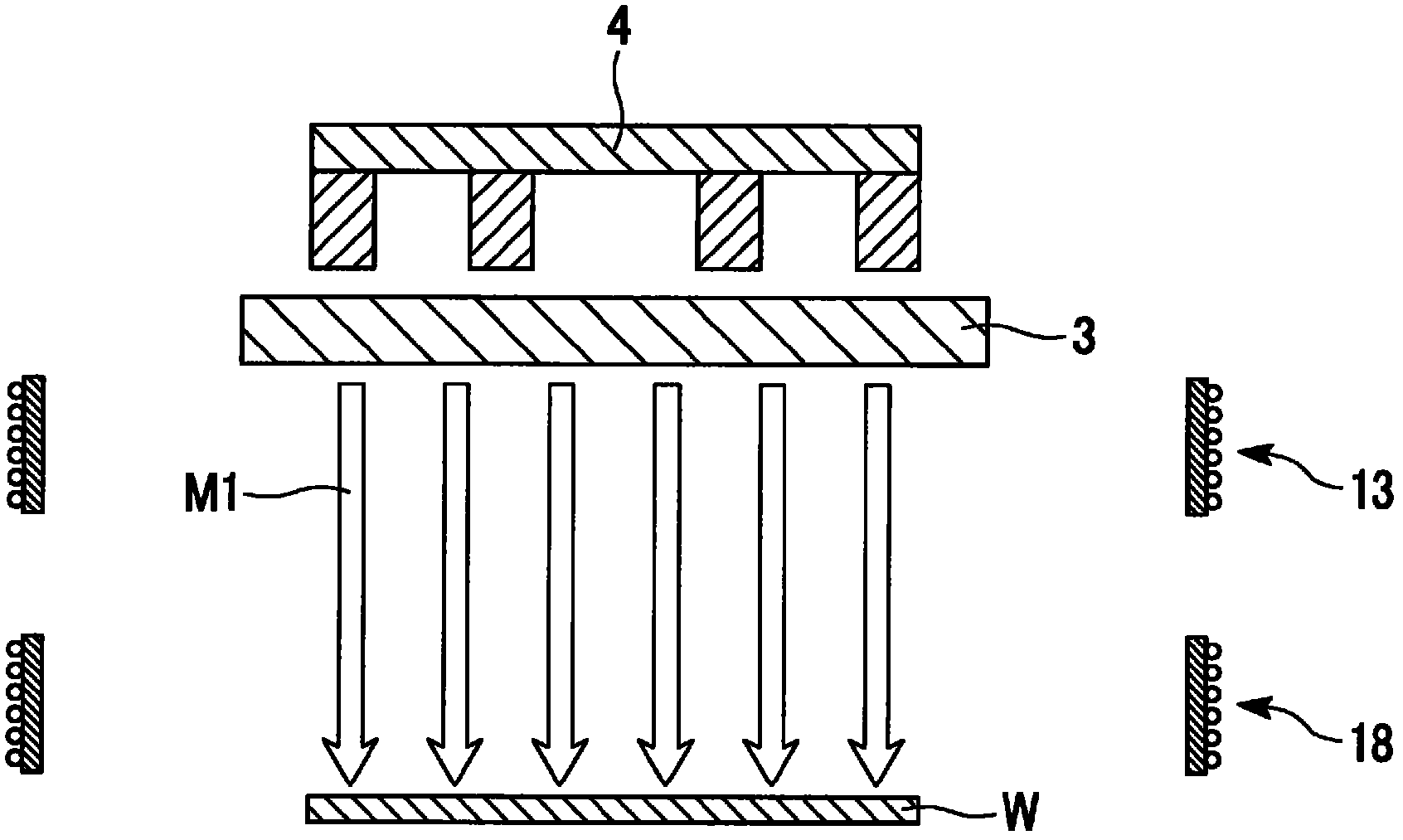

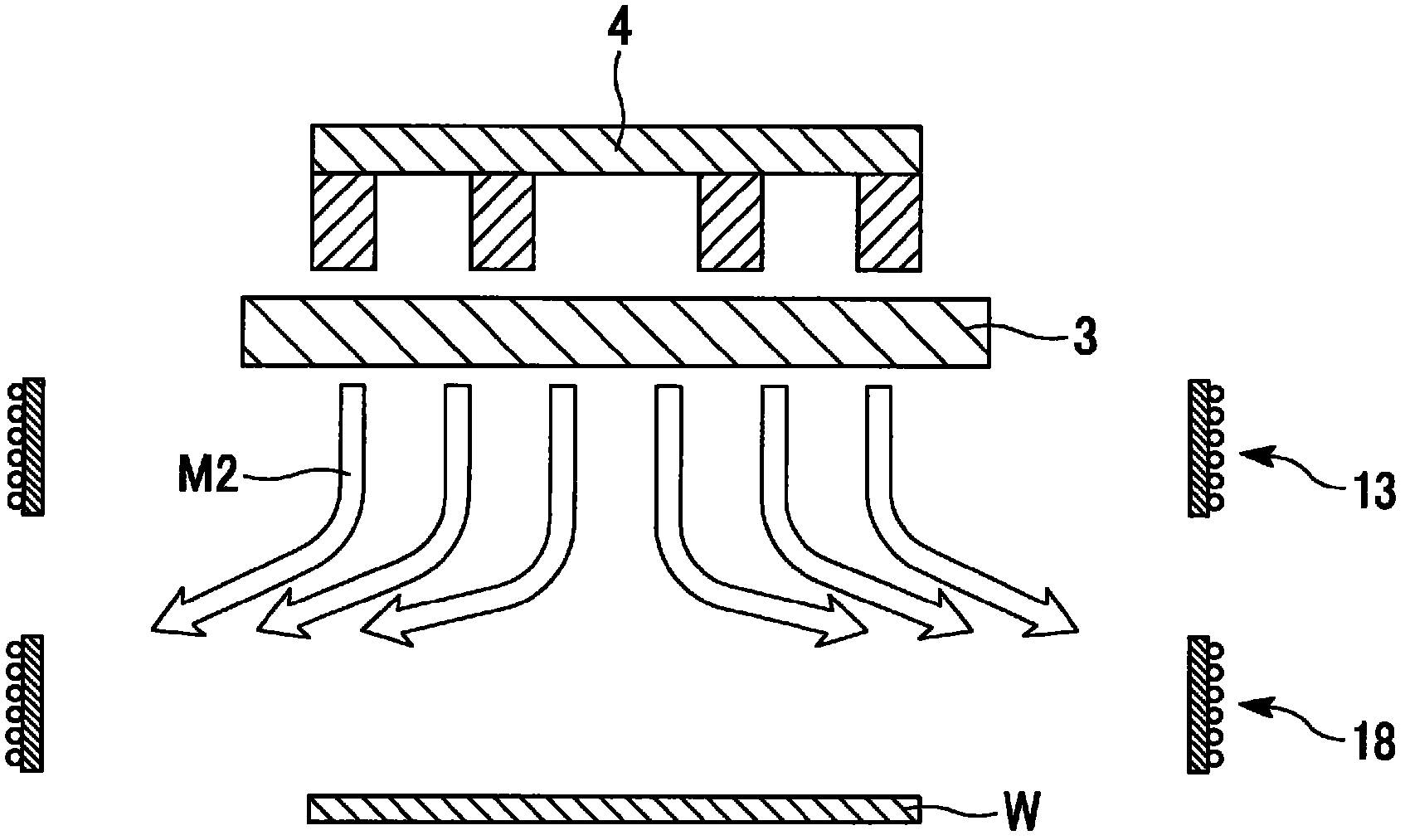

[0024] Hereinafter, embodiments of the film forming apparatus according to the present invention will be described based on the drawings.

[0025] In addition, in each drawing used in the following description, in order to make each constituent element a size that can be recognized on the drawings, the dimensions and ratios of each constituent element are suitably different from actual ones.

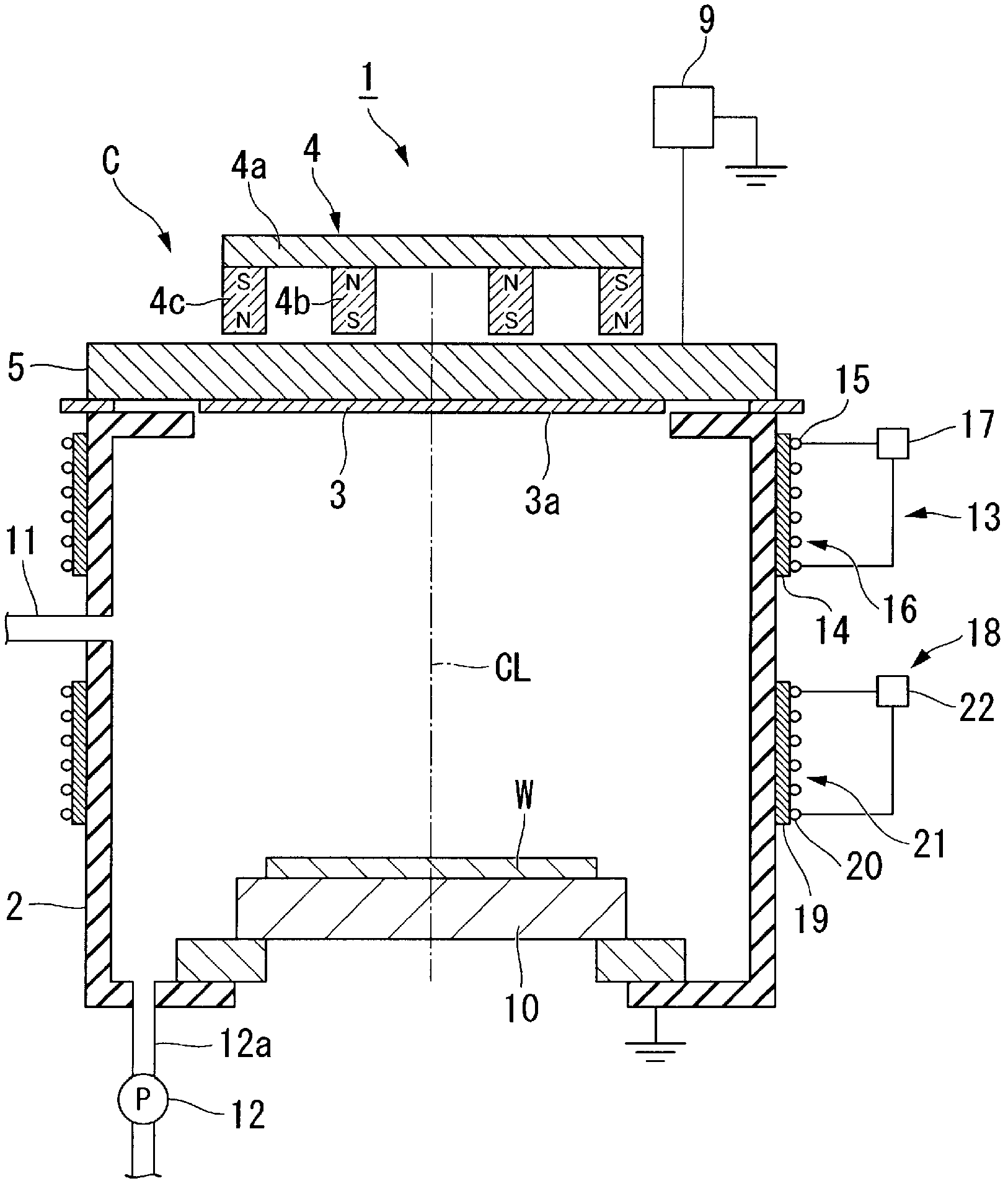

[0026] Such as figure 1 As shown, the film forming apparatus 1 is a DC magnetron sputtering film forming apparatus, and includes a vacuum chamber 2 (chamber) capable of generating a vacuum atmosphere.

[0027] A cathode unit C is attached to the ceiling portion of the vacuum chamber 2 .

[0028] In addition, in the following description, the position close to the top plate part of the vacuum chamber 2 is called "upper", and the position close to the bottom of the vacuum chamber 2 is called "lower".

[0029] The cathode unit C includes a target 3 mounted on a holder 5 . Furthermore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com