Process for producing SiC single crystal

A manufacturing method and single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as helplessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Growth of SiC single crystal was carried out in the following procedure.

[0049] Basic Crystal Growth Process

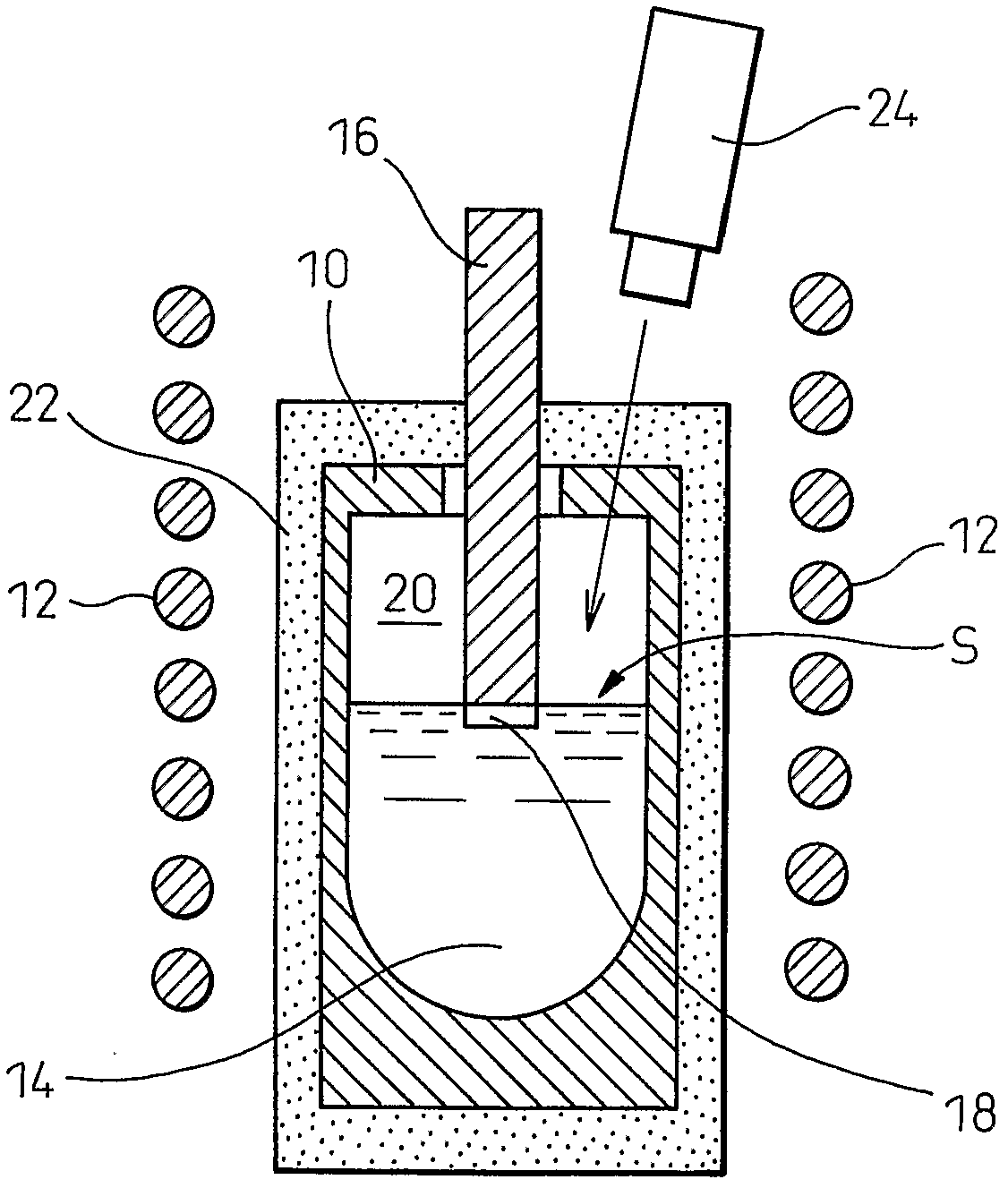

[0050] · Growth preparation (refer to figure 1 )

[0051] (1) The 4H-SiC seed crystal 18 is joined to the supporting shaft 16 made of graphite.

[0052] (2) Putting raw materials into the graphite crucible 10 .

[0053] (3) Put them as figure 1 constituted as shown.

[0054] (4) Ar20 at atmospheric pressure is introduced.

[0055] (5) Raise the temperature to the desired temperature.

[0056] ·Seed contact

[0057] (1) When the temperature of the melt 14 reaches a sufficient temperature, the support shaft 16 is lowered.

[0058] (2) After the seed crystal 18 comes into contact with the melt 14, the shaft 16 is lowered to a desired depth (*), and then the shaft is stopped. (*: In this embodiment, the seed crystal 18 stops at the position where it touches the liquid surface of the melt 14. In general, the seed crystal 18 sometimes sinks into the melt 1...

Embodiment 1

[0069] According to the present invention, the seed crystal contact is performed without temperature maintenance during the temperature increase.

[0070] The temperature of the melt was raised, and when the temperature reached 1900° C., seed crystal contact was performed immediately without temperature maintenance, the temperature was raised to 1950° C., and growth was performed at this temperature for 1 hour. A SiC single crystal with a thickness of about 60 μm can be obtained. The crystal was subjected to molten KOH etching, and the density of etch pits was 3×10 3 cm -2 . This corresponds to a seed defect density level of 10 3 cm -2 equal.

[0071] Compared with Comparative Example 2, the thickness of the obtained crystal was about 60 μm thinner. Also, although the seed contact was performed at the same temperature as in Comparative Example 2, the dislocation density was 2 orders of magnitude less. Thus, according to the present invention, by performing the seed crys...

Embodiment 2

[0081] Growth was performed using a solution in which 40 atomic % of Cr was added to Si. After raising the temperature to the growth temperature of 1950° C., seed contacting is carried out according to the invention without temperature holding. Growth was performed for 1 hour. The resulting SiC single crystal has an etch pit density of 7×10 4 cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com