Centrifugal compressor

A centrifugal compressor and gas compression technology, which is applied in mechanical equipment, engine manufacturing, machine/engine, etc., can solve problems such as leakage and compression efficiency reduction, and achieve the effect of reducing costs and maintaining high compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

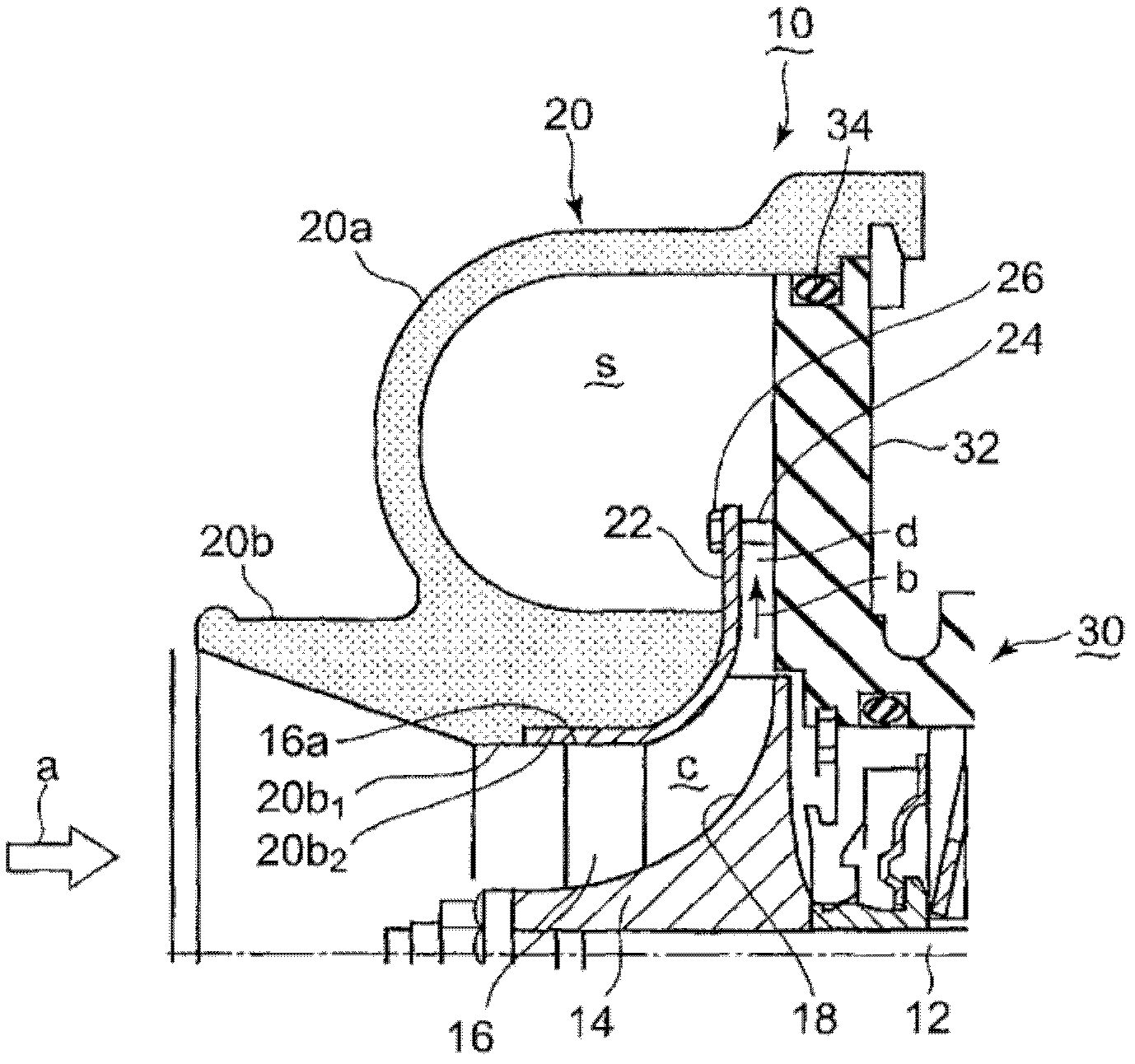

[0052] use figure 1 A first embodiment of the turbocharger of the present invention will be described. figure 1 A part of the compressor unit of the turbocharger 10 according to the present embodiment is shown. Such as figure 1 As shown, a rotating shaft 12 is disposed at the center of a resin housing 20, an impeller 14 is fixedly installed on the outer peripheral surface of the rotating shaft 12, and a plurality of blades 16 are radially arranged on the impeller 14 along the radial direction of the rotating shaft 12. . The hub surface 18 of the impeller 14 is curved from the axial direction of the rotating shaft 12 to the radial direction from the inlet side to the outlet side in the flow direction of the compressed gas (arrow a direction). The resin case 20 is composed of a spiral portion 20 a forming a spiral portion s inside and a flow path forming portion 20 b forming a flow path c of compressed gas.

[0053] The outer end of the blade 16 is formed with a curved pr...

no. 2 approach

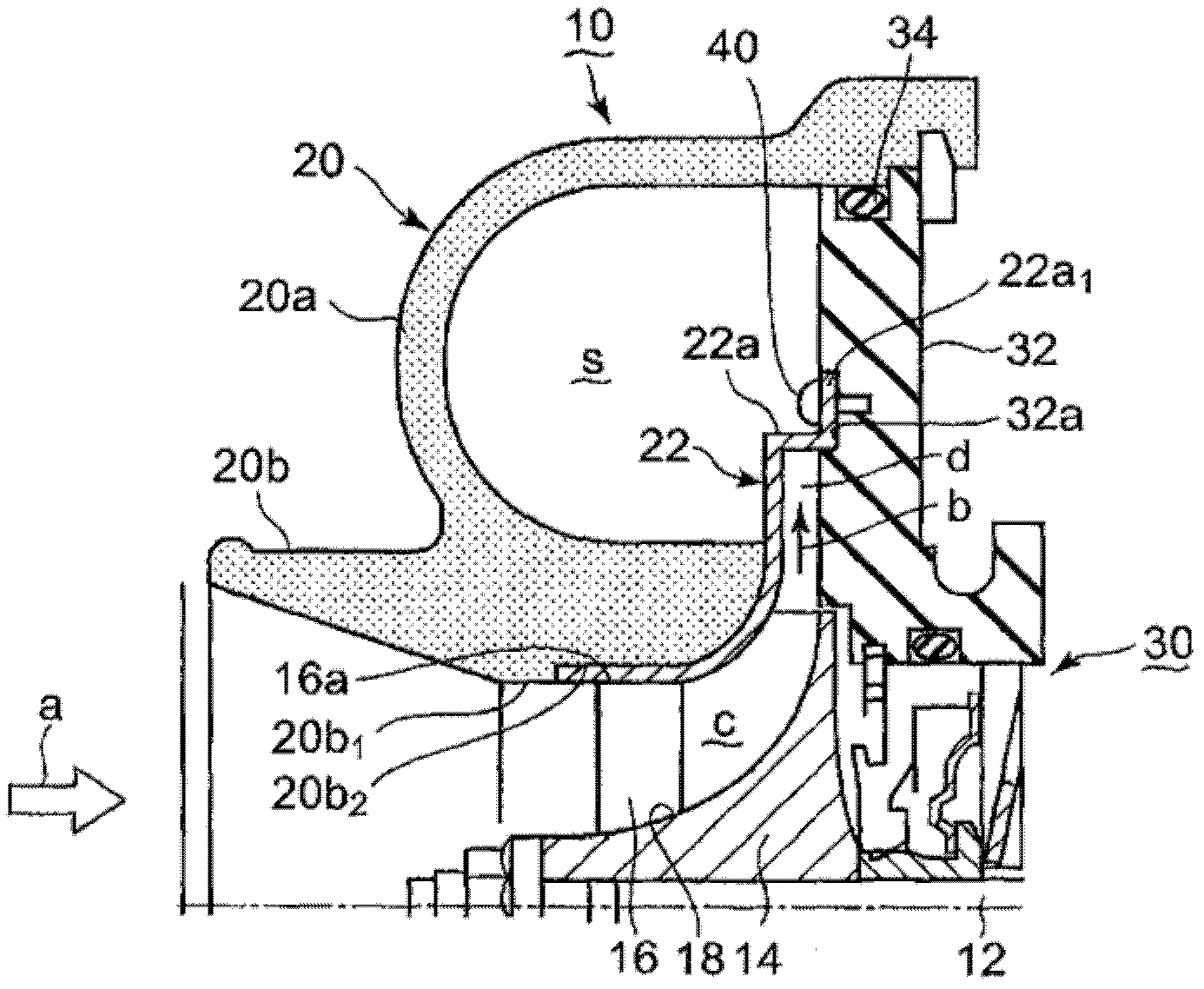

[0060] Next, use figure 2 A second embodiment of the turbocharger of the present invention will be described. Such as figure 2 As shown, in this embodiment, the downstream side end portion 22 a of the annular shroud 22 is formed with two bent portions, and extends until it contacts the partition wall 32 of the bearing housing 30 . A flange portion 22a is formed at the extended end portion 1 . On the other hand, the partition wall 32 is engraved with a flange portion 22a for fitting. 1 The concave portion 32a. Flange part 22a 1 It is connected to the recessed part 32a by the bolt 40.

[0061] In addition, since the flange portion 22a 1 Since it is partially formed in the circumferential direction of the impeller 14, the downstream end portion 22a of the shroud 22 does not block the diffuser d, and does not hinder the flow of the compressed gas in the diffuser d. Other structures are the same as those of the above-mentioned first embodiment. The same reference numeral...

no. 3 approach

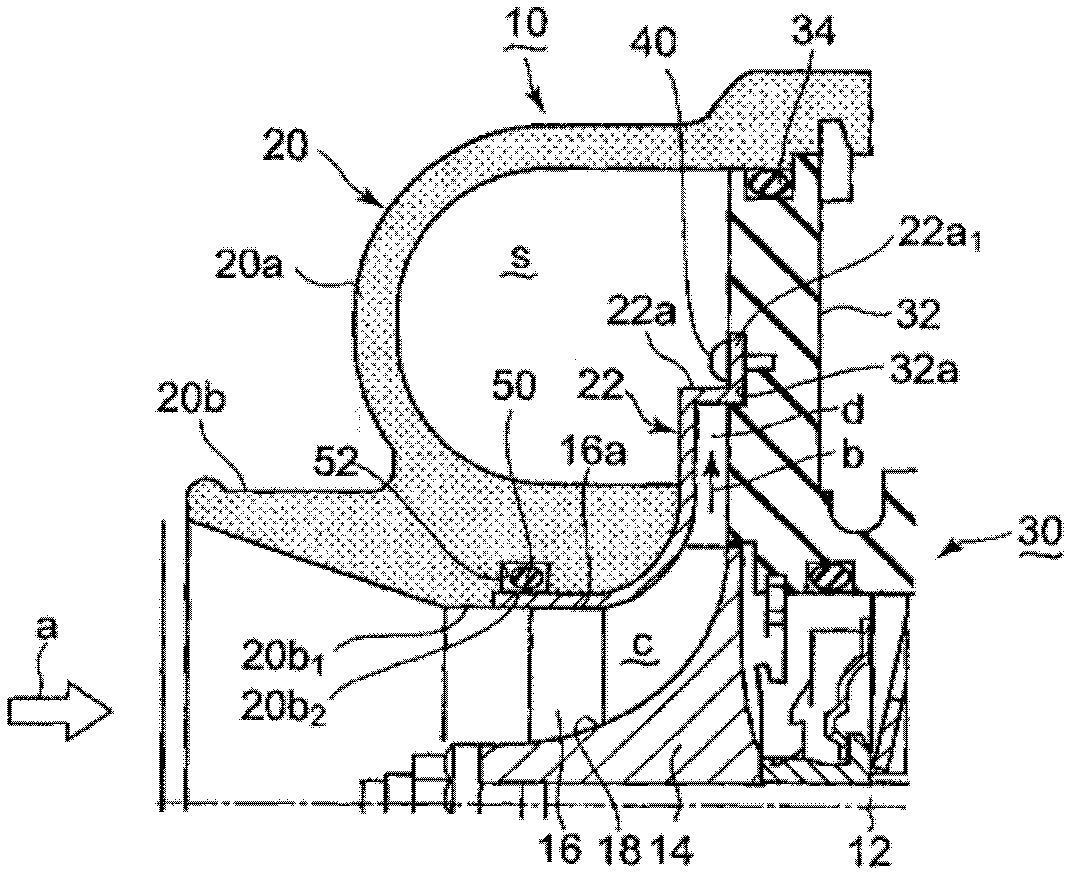

[0064] Next, use image 3 A third embodiment of the turbocharger of the present invention will be described. Such as image 3 As shown, in the present embodiment, in the inlet region of the flow path c, the inner wall 20b of the flow path forming portion 20b engraved on the resin case 20 1 The recess 20b 2 , engraved housing groove 52, in the housing groove 52 housing rubber or resin sealing ring 50. The other structures are the same as those of the above-mentioned second embodiment.

[0065] According to this embodiment, even if the resin case 20 is thermally deformed, the recess 20b 2 When there is a gap between the back surface of the annular shutter 2 (made of metal such as aluminum or carbon steel or ceramics), the compressed gas does not enter the recess 20b because the seal ring 50 is provided. 2 and the annular shroud 22, therefore, the compression efficiency of the compressor will not decrease.

[0066] At the inlet of the impeller 14, the temperature of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com