Fault detection in electroluminescent displays

An electroluminescent display and fault technology, applied in electroluminescent light sources, electric light sources, static indicators, etc., can solve the problems of low electrical performance, limitations on the size and quantity of light-emitting components, and complex substrate wiring requirements, and achieve The effect of improving access, improving performance, and increasing manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

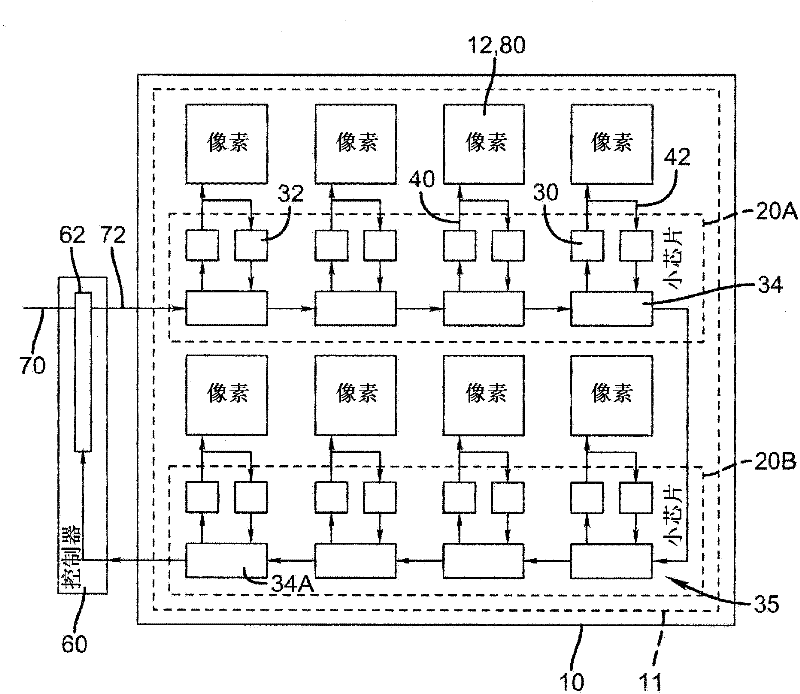

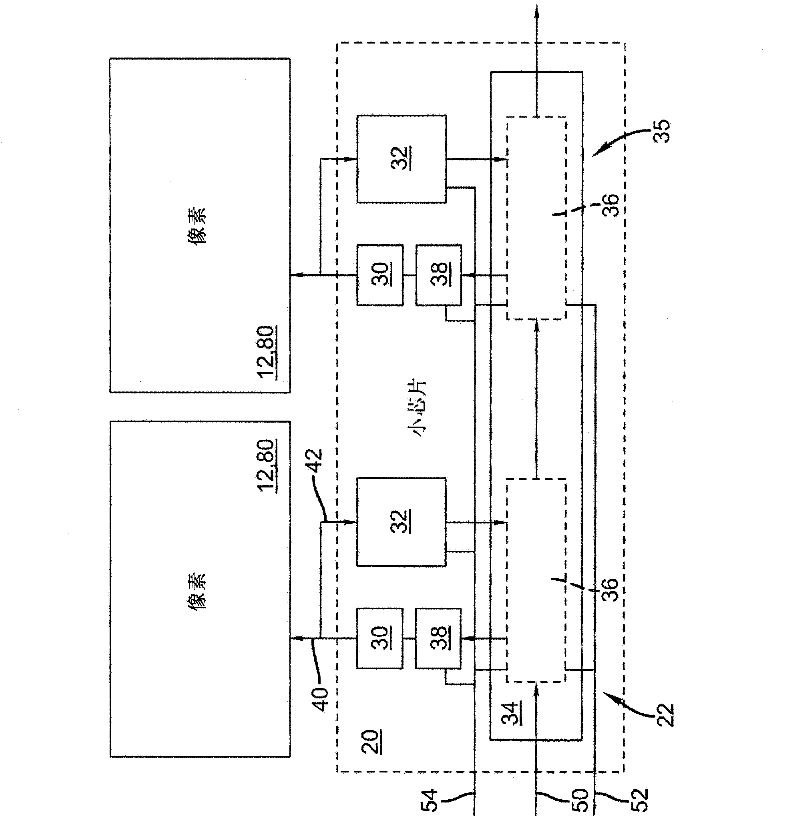

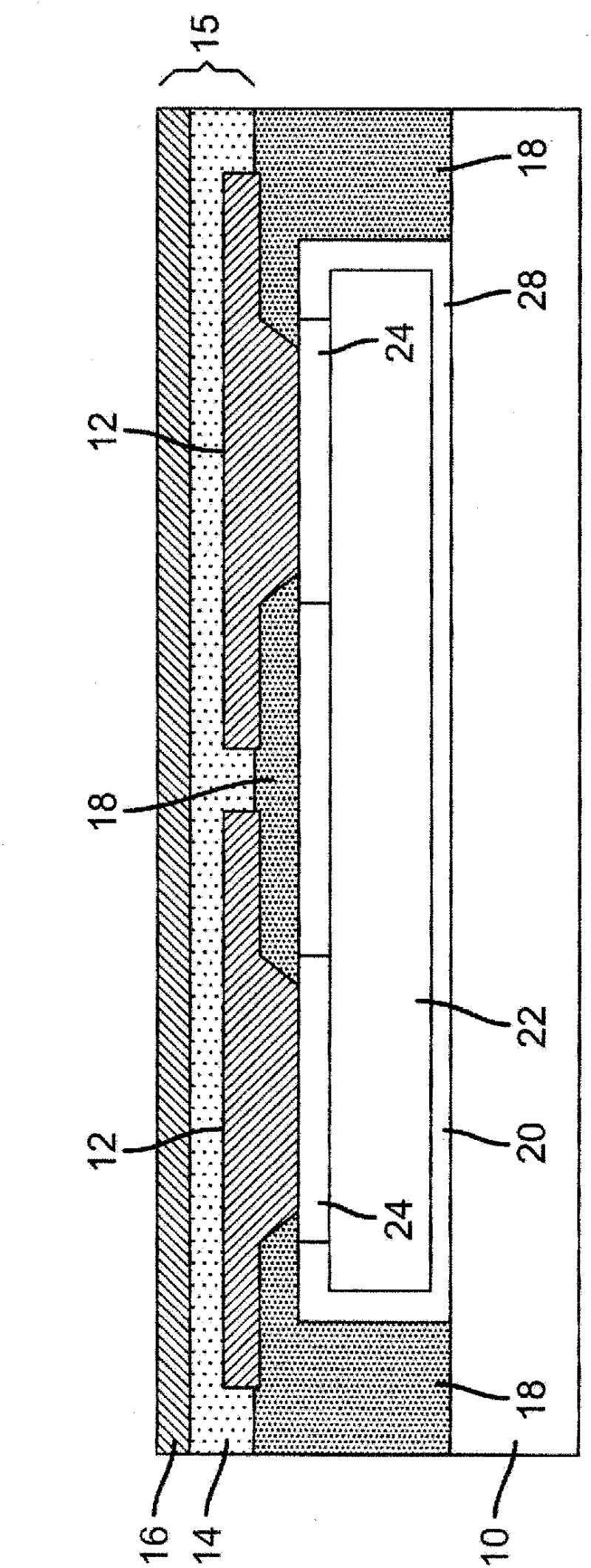

[0027] Reference figure 1 with image 3 In one embodiment of the present invention, the display device includes a substrate 10 having a display area 11. A plurality of pixels 80 are formed on the display substrate 10 and in the display area 11. Each pixel includes: a first electrode 12, one or more layers of luminescent material 14 formed on the first electrode 12, and The second electrode 16 formed on or more layers of the luminescent material 14 emits light in response to the current flowing through the luminescent material 14 from the first electrode 12 and the second electrode 16 by the driven electric signal. For each driven electrical signal, a drive circuit 30 is provided in the display area 11, and the drive circuit 30 provides the first electrode 12 or the second electrode 16 of the pixel 80 with the driven electrical signal corresponding to the desired pixel brightness value 72. Signal 40, the driven electrical signal 40 generates a current flowing through the lumines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com