Multi-beam laser power control circuit and image forming apparatus using the same

A technology of power control and automatic power control, which is applied to lasers, equipment for electrical recording technology using charge patterns, laser components, etc., to achieve the effect of reducing the time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

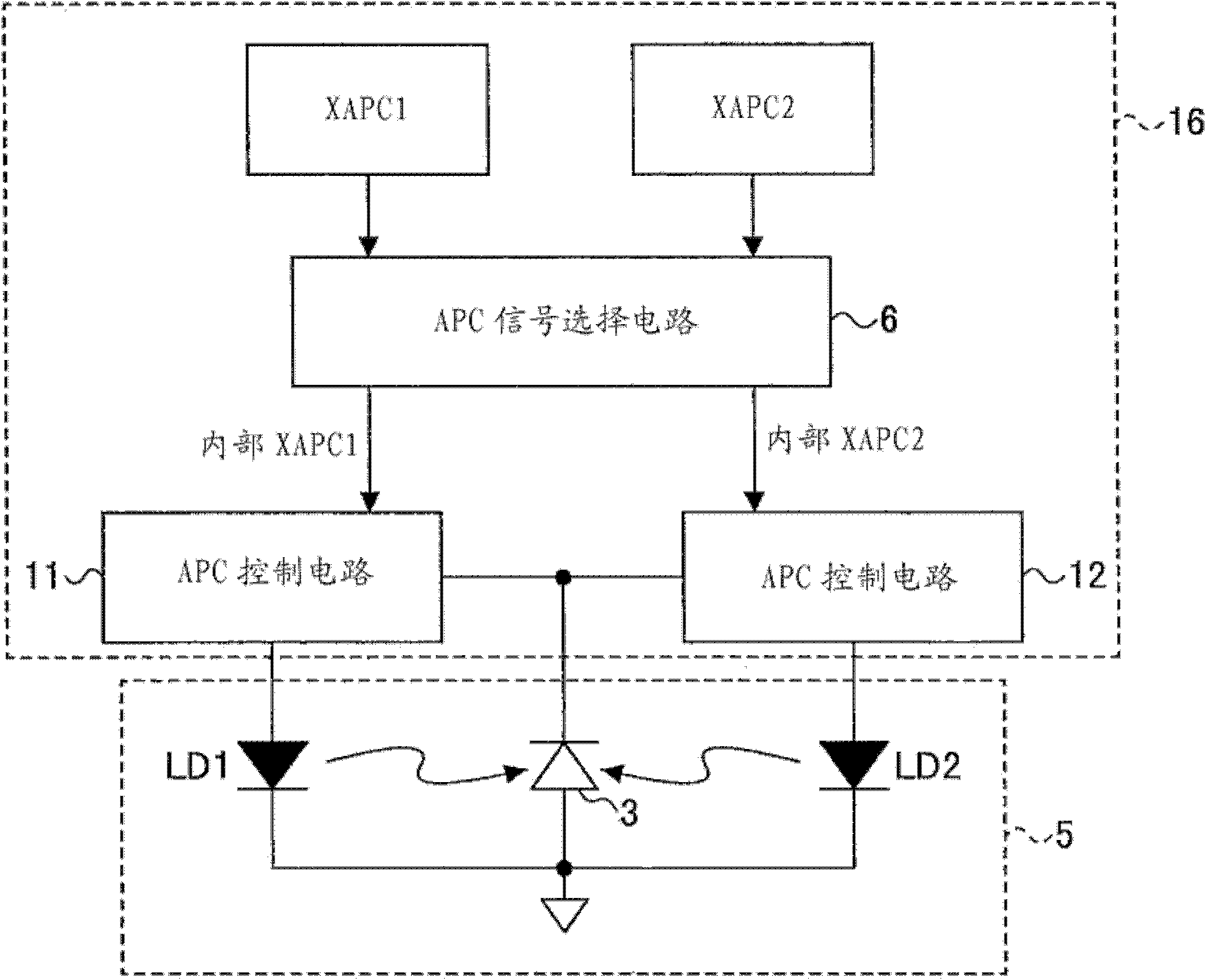

[0044] figure 1 is a schematic block diagram of the multi-beam laser power control circuit 16 according to the first embodiment of the present invention. exist figure 1 In , in addition to the block diagram of the multi-beam laser power control circuit 16, a block diagram of the semiconductor laser array (multi-beam unit) 5 is also included.

[0045] Such as figure 1 As shown, the semiconductor laser array (multi-beam unit) 5 includes two semiconductor lasers ( LD1 , LD2 ) and one photodiode 3 corresponding to the two semiconductor lasers ( LD1 , LD2 ). in addition, figure 1 The multi-beam laser power control circuit 16 includes an APC signal selection circuit 6, an APC control circuit 11 for LD1, an APC control circuit 12 for LD2, and an APC execution signal input terminal for externally inputting an APC execution signal. The APC execution signal is input to each APC execution signal input terminal, and the number of APC execution signals corresponds to the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com