Numerical pressure-controllable gold blocking die cutting platform

A platform and pressure technology, applied in the field of digital pressure controllable bronzing die-cutting platform, can solve the problems of short residence time, high processing precision, and difficult processing, so as to reduce material cost and manufacturing cost, improve equipment service life, improve The effect of platform speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

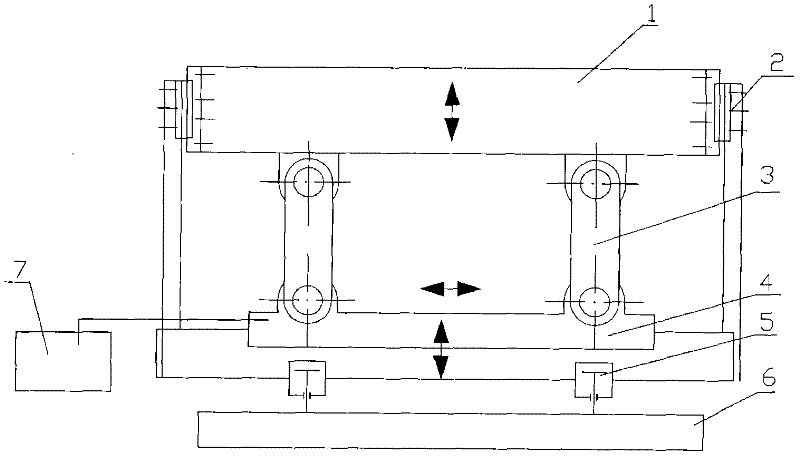

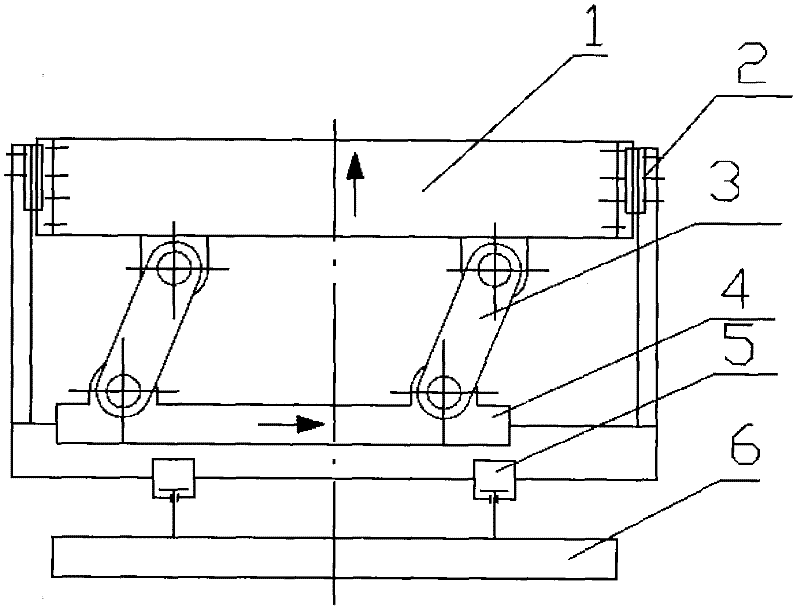

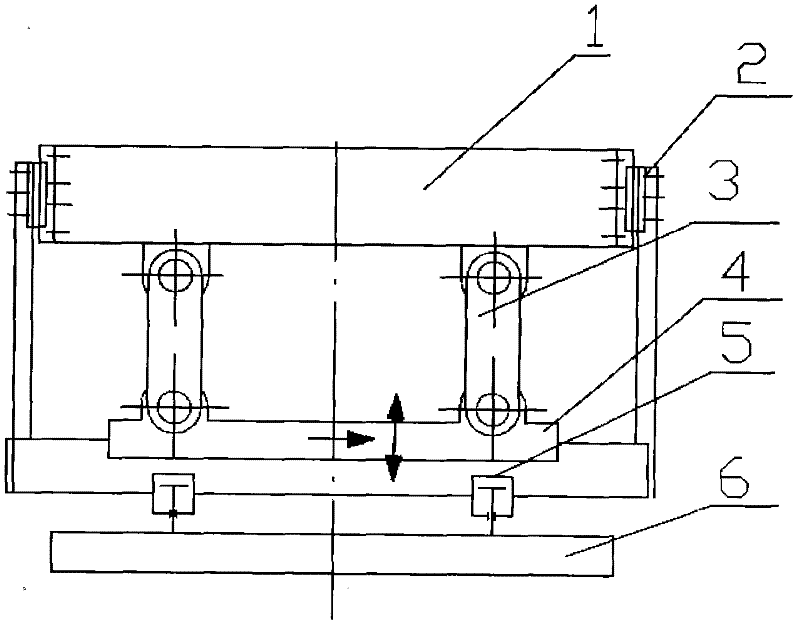

[0021] see Figure 1 to Figure 7 As shown, it is the first embodiment of a digital pressure controllable bronzing die-cutting platform provided by the present invention. The digitalized pressure controllable bronzing die-cutting platform includes a moving platform 1, a guide system 2, and a The swing rod assembly 3, the linear device 4 connected to the swing rod assembly 3, the constant pressure device 5 located below the linear device 4, the base 6 located below the constant pressure device 5 and the linear device 4 connected External digital controller7. Both ends of the swing link assembly 3 are respectively pivotally matched with the moving platform 1 and the linear device 4 , so that the swing link assembly 3 can perform pivotal movement around the joint relative to the moving platform 1 and the linear device 4 . The linear device 4 can be composed of a controllable hydraulic system or a controllable air pressure system or a controllable servo system or a controllable ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com