Gapless hydraulic driving following support system

A support system and gapless technology, which is applied in the field preparation of pillars and building components, construction, etc., can solve the problems of affecting the effective accuracy of supports, large errors in automatic follow-up measurement and control, and occupying a large jacking space, so as to save system configuration Cost, achieving constant and following, strong wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

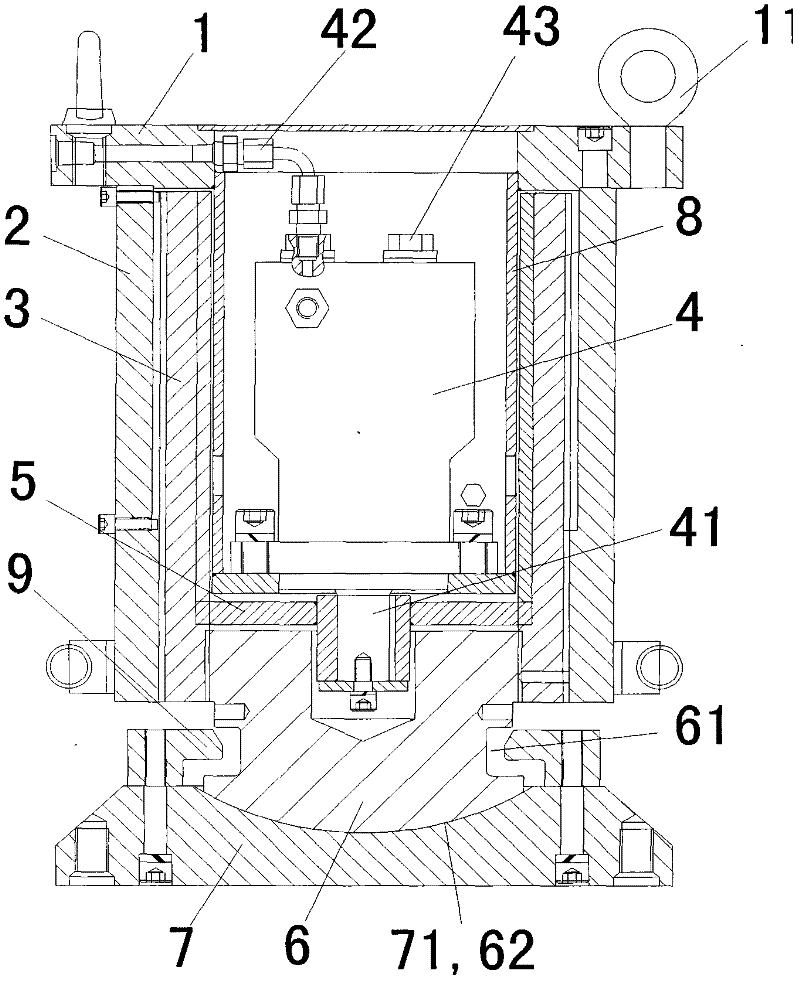

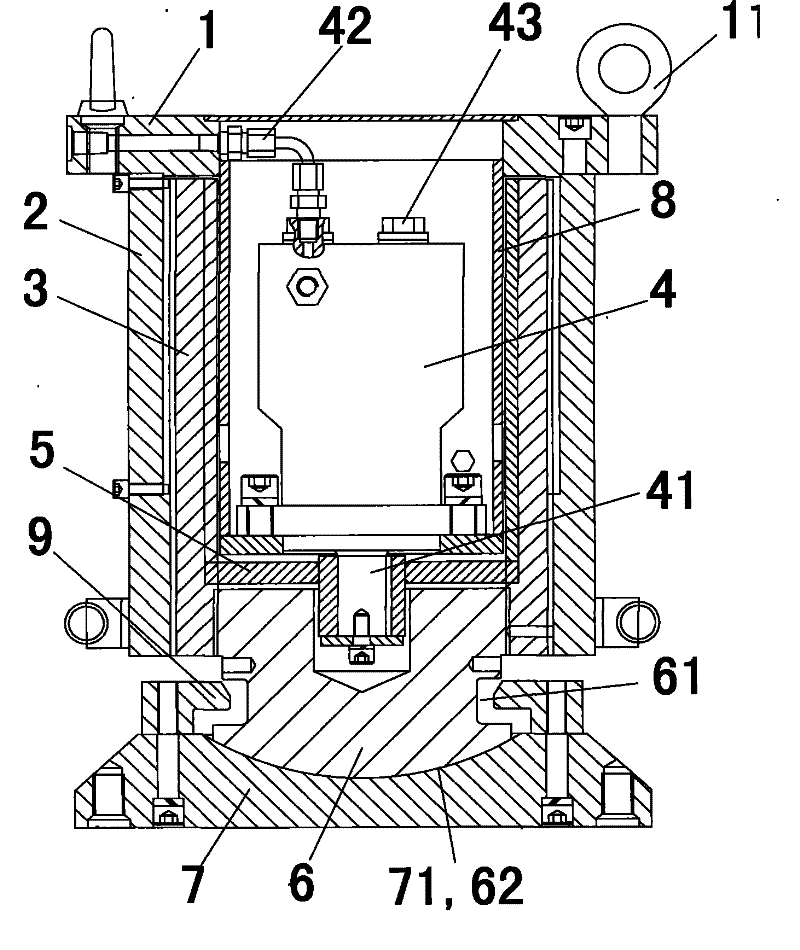

[0031] see figure 1 , the gapless hydraulic drive follow support system of the present invention, including cover 1, outer cover 2, follow inner cover 3, hydraulic motor 4, rotating plate 5, follow head 6 and follow seat 7.

[0032] The upper cover 1 is provided with a suspension ring 11 .

[0033] The outer cover 2 is fixedly connected to the lower part of the upper cover 1, and an internal thread is provided at the lower part of the inner wall of the outer cover 2, and the upper part and the middle part of the inner wall of the outer cover 2 are retracted inwardly to form a concave platform.

[0034] Follow the inner sleeve 3 to be threadedly connected with the outer sleeve 2 and move up and down along the outer sleeve, follow the outer wall of the inner sleeve 3 to be provided with an external thread adapted to the inner thread of the outer sleeve 2, and follow the middle part of the inner wall of the inner sleeve 3 to be provided with an internal thread.

[0035] The hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com