Apparatus for transporting fuel

A fuel and output channel technology is applied in the field of devices for conveying fuel to achieve the effects of simple assembly and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

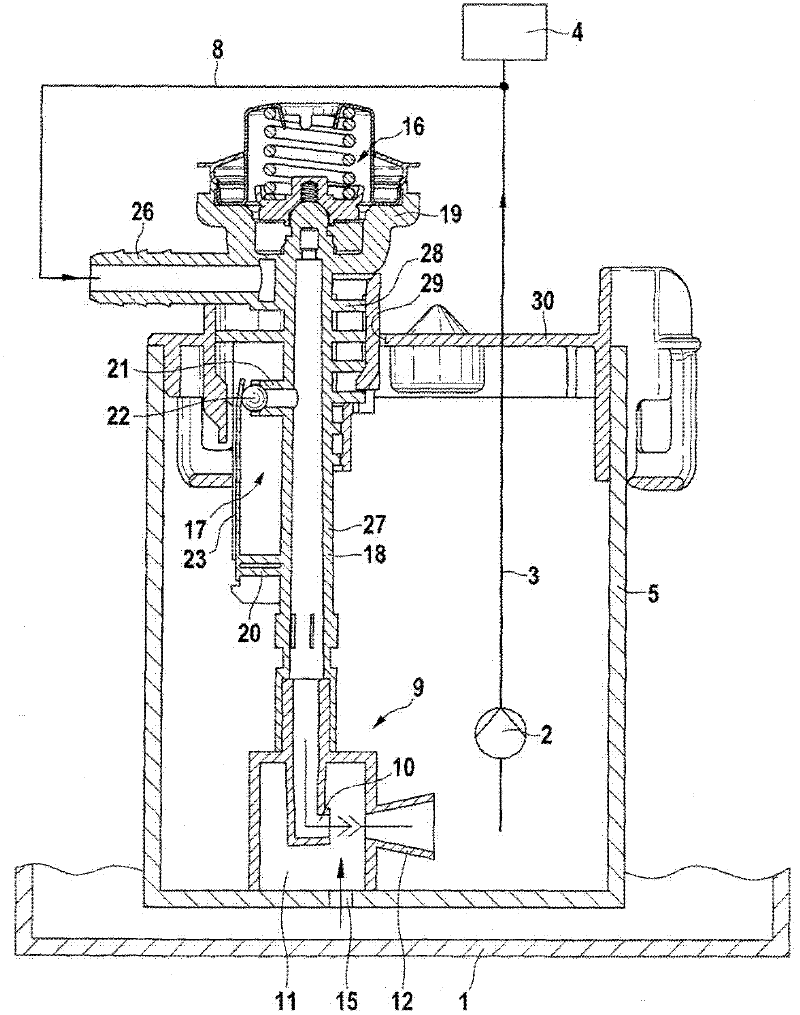

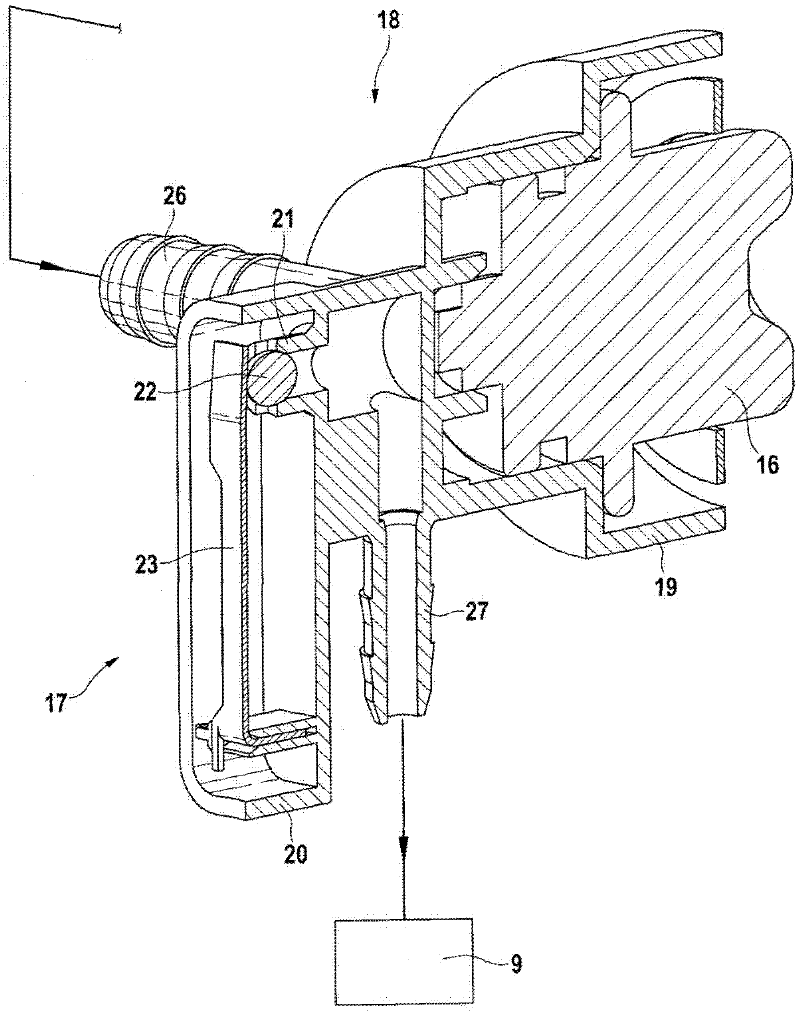

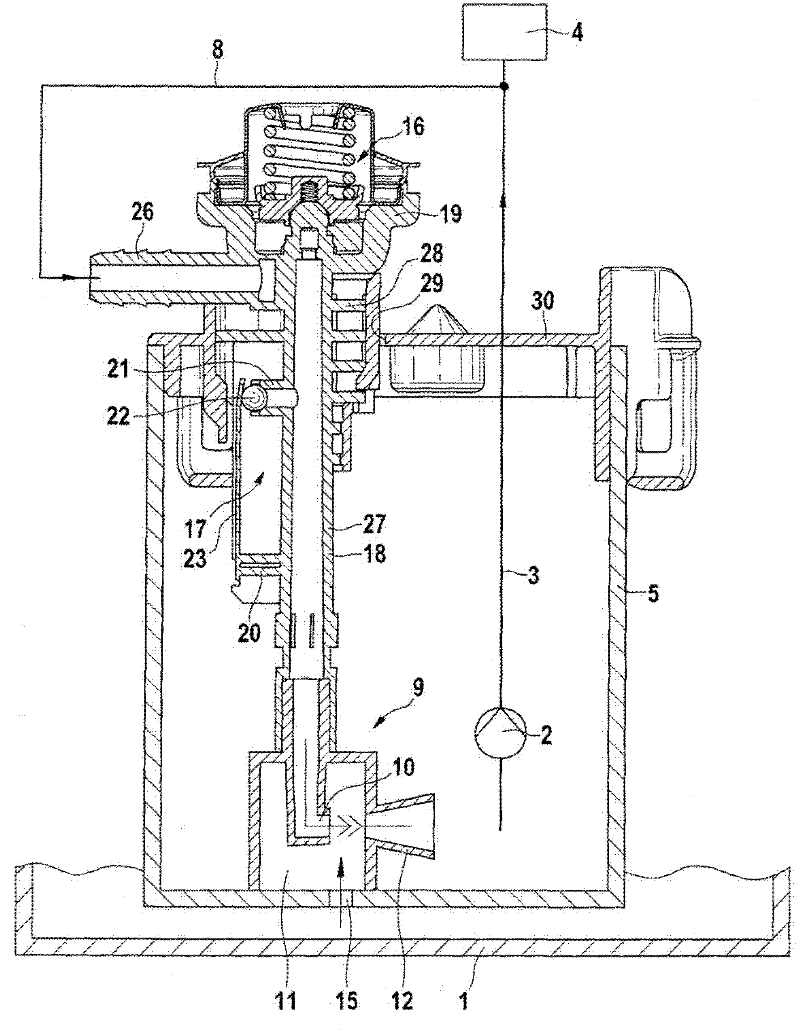

[0012] figure 1 A device for conveying fuel with a drive line component according to a first exemplary embodiment is shown in section.

[0013] The device for delivering fuel is arranged in fuel tank 1 and delivers fuel from fuel tank 1 under increased pressure via pressure line 3 to internal combustion engine 4 by means of a delivery unit 2 , for example an electrically operated fuel pump.

[0014] The delivery unit 2 is arranged in a storage container 5 which maintains sufficient fuel for the delivery unit 2, so that the delivery unit is even in the low-fill state of the fuel tank 1 and when accelerating, braking, cornering and / or Fuel can be pumped when climbing hills.

[0015] From the pressure line 3 of the device branches a drive line 8 which drives a suction jet pump 9 for actively filling the storage container 5 . The drive line 8 can obviously also be supplied with fuel by a return (not shown) of the internal combustion engine 4 or in some other way. The drive line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com