Method and device for monitoring bearing failure of power generator

A generator bearing and fault monitoring technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of difficult measurement, unsatisfactory effect, and inability to accurately reflect the bearing operation status, and achieve the effect of accurate, effective and monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

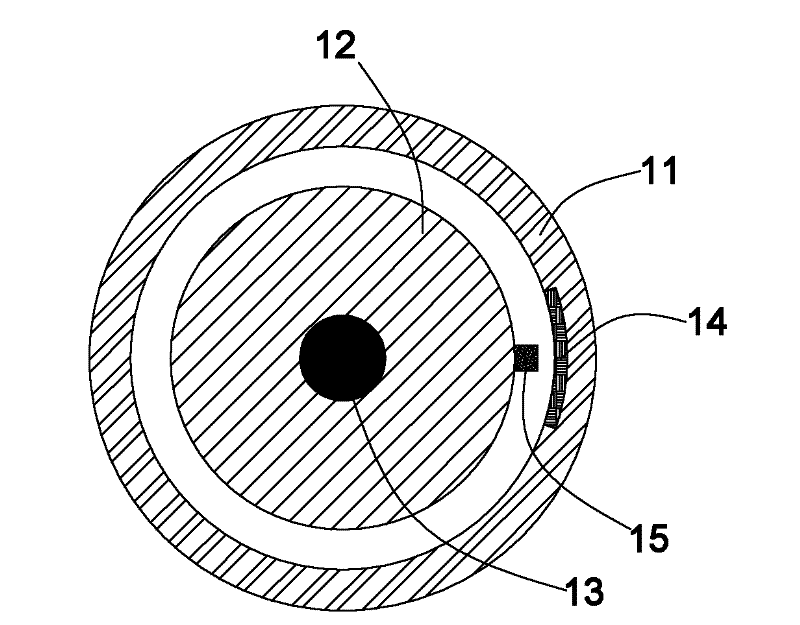

[0021] Generally speaking, for generators, such as wind turbines, the position (radial and axial) between the stator and the rotor is fixed by bearings. The generator speed is low and the mass of the rotor is large, so low speed and heavy load are the main factors. Operating characteristics, this operating characteristic determines that the characteristics of vibration and shock signals must be insensitive, while the displacement signal, that is, the relative position change between the rotor and the stator, is the most sensitive and direct characteristic parameter.

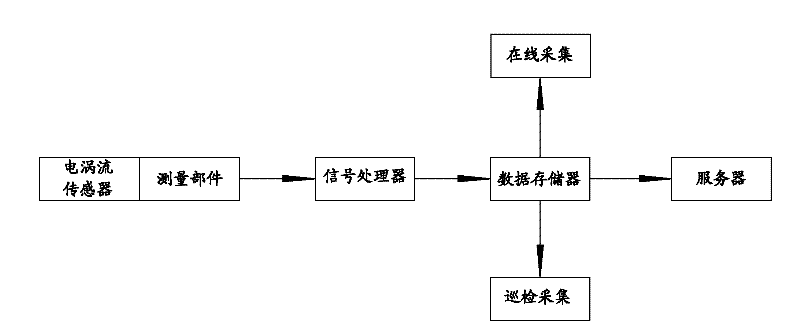

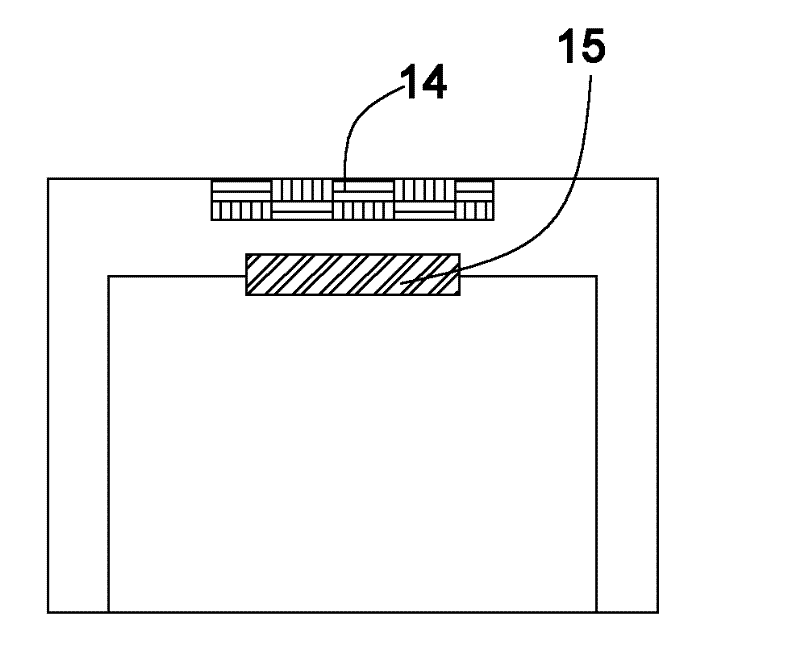

[0022] The present invention uses an eddy current sensor to measure the relative position between the rotor and the stator, and the eddy current sensor outputs two parameters of dynamic voltage and static voltage, and the dynamic voltage represents the position caused by pitting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com