Novel numerical control machine tool fault diagnosis system and method

A fault diagnosis system, a technology of CNC machine tools, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as distortion or attenuation, complex process, time-consuming, etc., to improve operating efficiency, simple hardware structure, The effect of reducing downtime for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

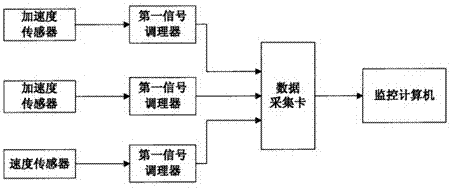

[0026] As shown in Figure 1, a CNC machine tool fault diagnosis system includes:

[0027] Two acceleration sensors and one speed sensor are used to obtain vibration signals generated by CNC machine tools;

[0028] Two first signal conditioners are respectively connected to the output end of one of the acceleration sensors, and are used to condition and output the signals output by the acceleration sensors;

[0029] The second signal conditioner is connected to the output terminal of the speed sensor, and is used for conditioning and outputting the signal output by the speed sensor;

[0030] A data acquisition card, connected to the first signal conditioner and the second signal conditioner, for collecting and outputting the signal outputted by the first signal conditioner and the second signal conditioner after conditioning;

[0031] The monitoring computer is connected with the output end of the data acquisition card, and is used to calculate and anal...

Embodiment 2

[0036] A method for fault diagnosis of a numerically controlled machine tool, comprising the following steps:

[0037] 1) The vibration signal acquisition step is to obtain the vibration signal generated by the CNC machine tool through two acceleration sensors and a speed sensor;

[0038] 2) a signal conditioning step, conditioning and outputting the signal output by the acceleration sensor through two first signal conditioners; conditioning and outputting the signal output by the speed sensor through a second signal conditioner;

[0039] 3) a data collection step, for collecting and outputting signals output by the first signal conditioner and the second signal conditioner after conditioning;

[0040] 4) The signal analysis step is used to calculate and analyze the vibration signal generated by the CNC machine tool, so as to realize the intelligent fault diagnosis of the machine tool.

[0041] Among them, the specific analysis method may be to analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com