Gallotannic compounds for lithographic printing plate coating compositions

一种平版印刷版、化合物的技术,应用在平版印刷设备、印刷、印刷工艺等方向,能够解决图象浮散、降低机械强度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

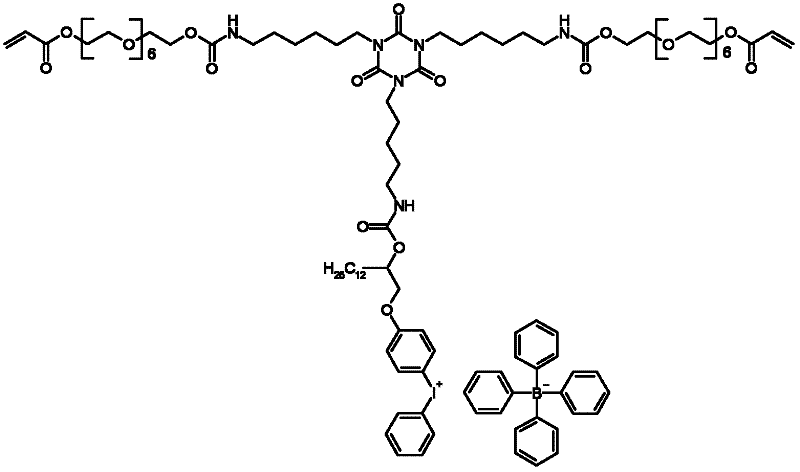

[0313] Synthesize as follows figure 2 Shown gallotannin compound RGT-01: 155 grams of methacrylic acid-2-isocyano group in 500 grams of anhydrous 1,3-dioxolane will be added to 500 grams of anhydrous 1,3-dioxolane under 50°C, oxygen atmosphere and continuous stirring. The ethyl ester (10 equivalents) was added to a reaction flask containing 800 grams of anhydrous 1,3-dioxolane, in which 170.1 grams of gallotannin (1 equivalent) and 0.5 grams of dibutyl tin dilaurate were dissolved. After 30 hours of reaction, a sample of the reaction mixture was taken out of the reaction flask. The FTIR spectrum recorded on the KBr disc did not show a -N=C=O peak at 2274 cm-1, which indicated that the reaction was completed. 1,3-Dioxolane was used to adjust the solid content of RGT-01 to 20% by weight.

Embodiment 2

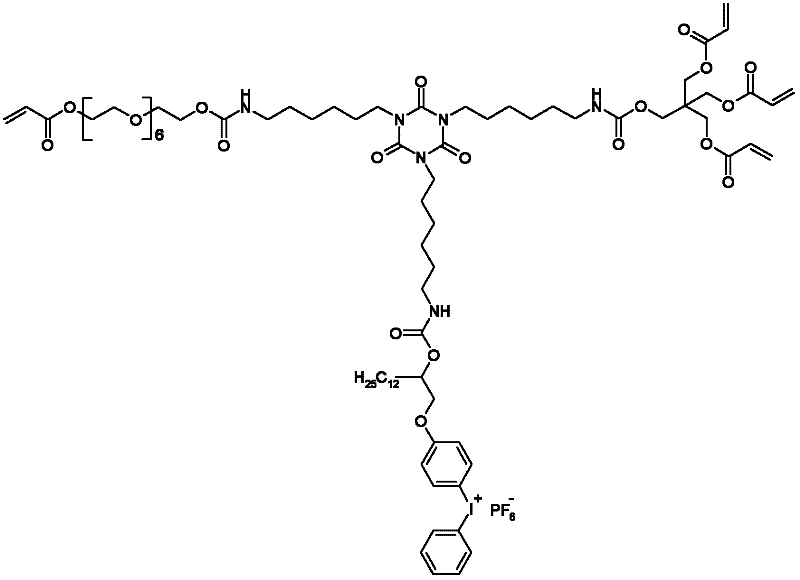

[0315] Synthesize as follows image 3 Shown gallotannin compound RGT-02: Under a nitrogen atmosphere and continuous stirring, slowly add 42.0 grams of sodium hydride (10.5 equivalents) to the reaction flask containing 500 grams of anhydrous N,N-dimethylacetamide , In which 170.1 grams of gallotannin are dissolved. After about 3 hours, the hydrogen by-product stopped releasing, and a solution containing 300 grams of N,N-dimethylacetamide and 209 grams of MMEA (10 equivalents) was slowly added to the reaction mixture. The reaction was stopped after 10 hours at 50°C. The solvent was removed under vacuum using a rotary evaporator until dry. The obtained solid was dissolved in anhydrous 1,3-dioxolane to provide a 20% solid solution. Then it was gravity filtered to remove the sodium chloride by-product.

Embodiment 3

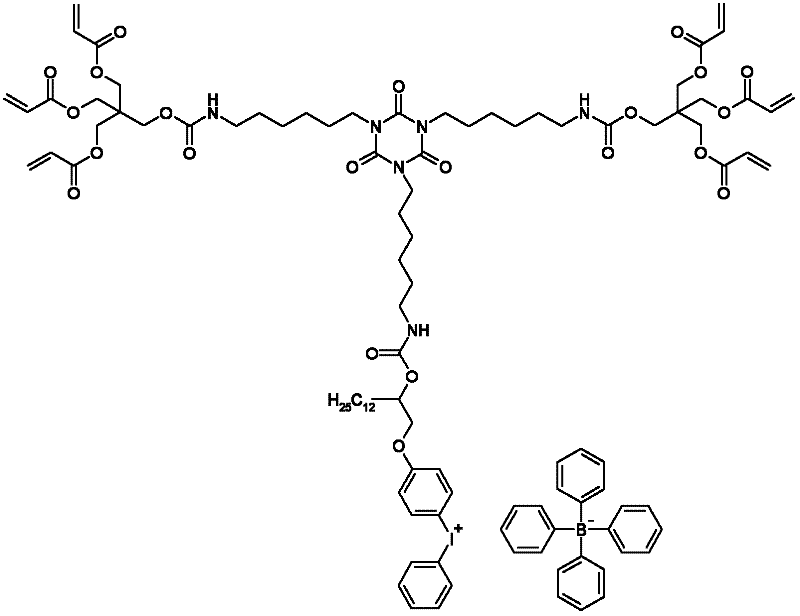

[0317] The Gallo-25X was synthesized by the following: At 57° C., under an oxygen atmosphere and continuous stirring, 150 g 1,3-dioxolane solution containing 37.4 g NCO-0747 was slowly added to 100 g 1,3-dioxolane Ring, 17.0 grams of gallotannin, and 0.1 grams of dibutyl tin dilaurate. After 5 hours of reaction, the sample was taken out of the reaction for FTIR analysis. At 2210cm -1 The -NCO stretch band disappears, which means the reaction is complete. The solution was adjusted with 1,3-dioxolane to obtain 20% solids weight, which is a solution ready to be used for coating the plate. The ideal chemical structure of Gallo-25X is Figure 4 Shown. Gallotannins with initiator

[0318] Initiator for hot plate

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com