Semiconductor light-emitting element manufacturing method, lamp, electronic device, and mechanical apparatus

A technology of light-emitting element and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, lighting devices, etc., can solve the problems of p-type semiconductor layer obstacles and the lack of resistivity p-type semiconductor layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

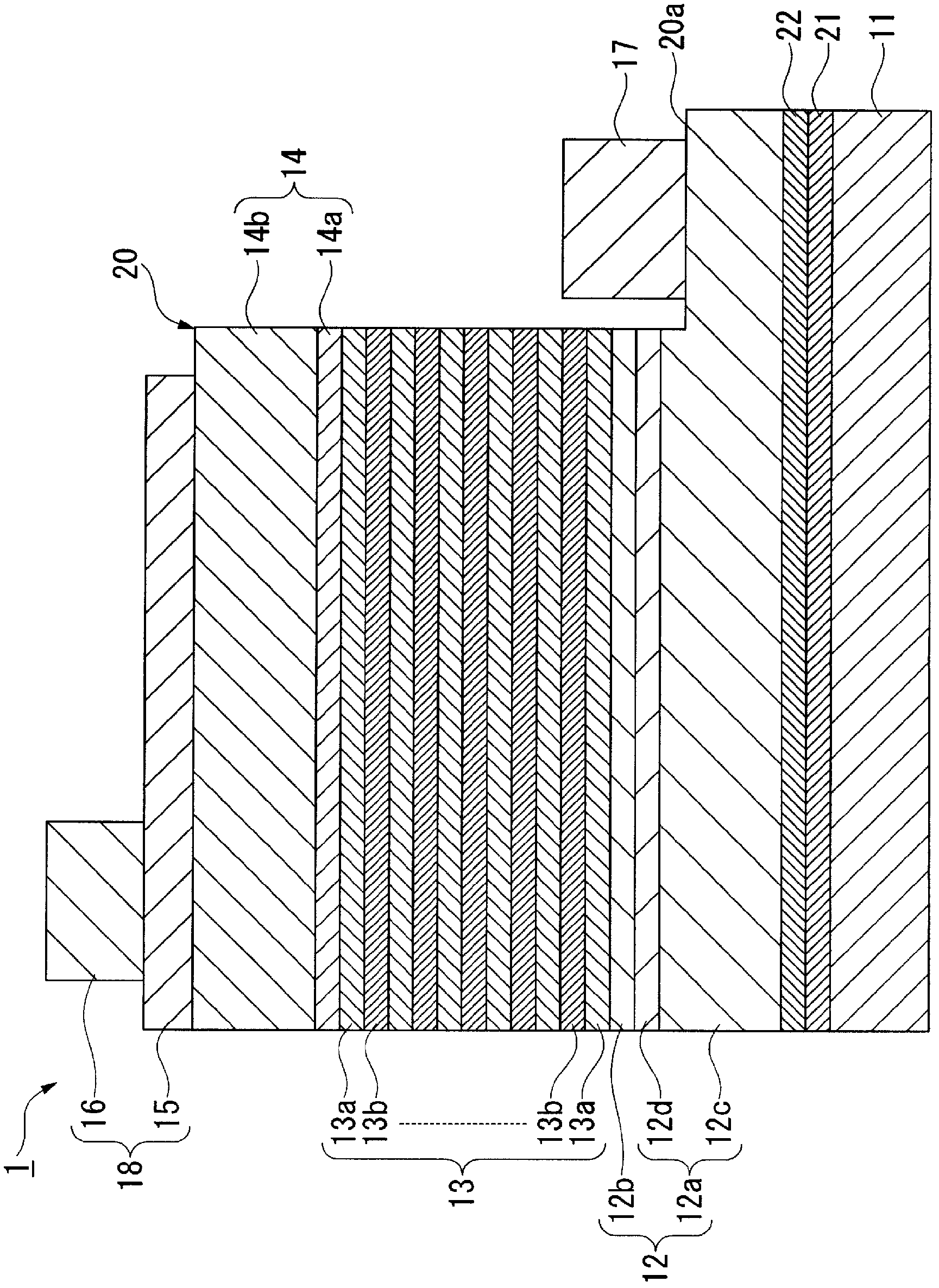

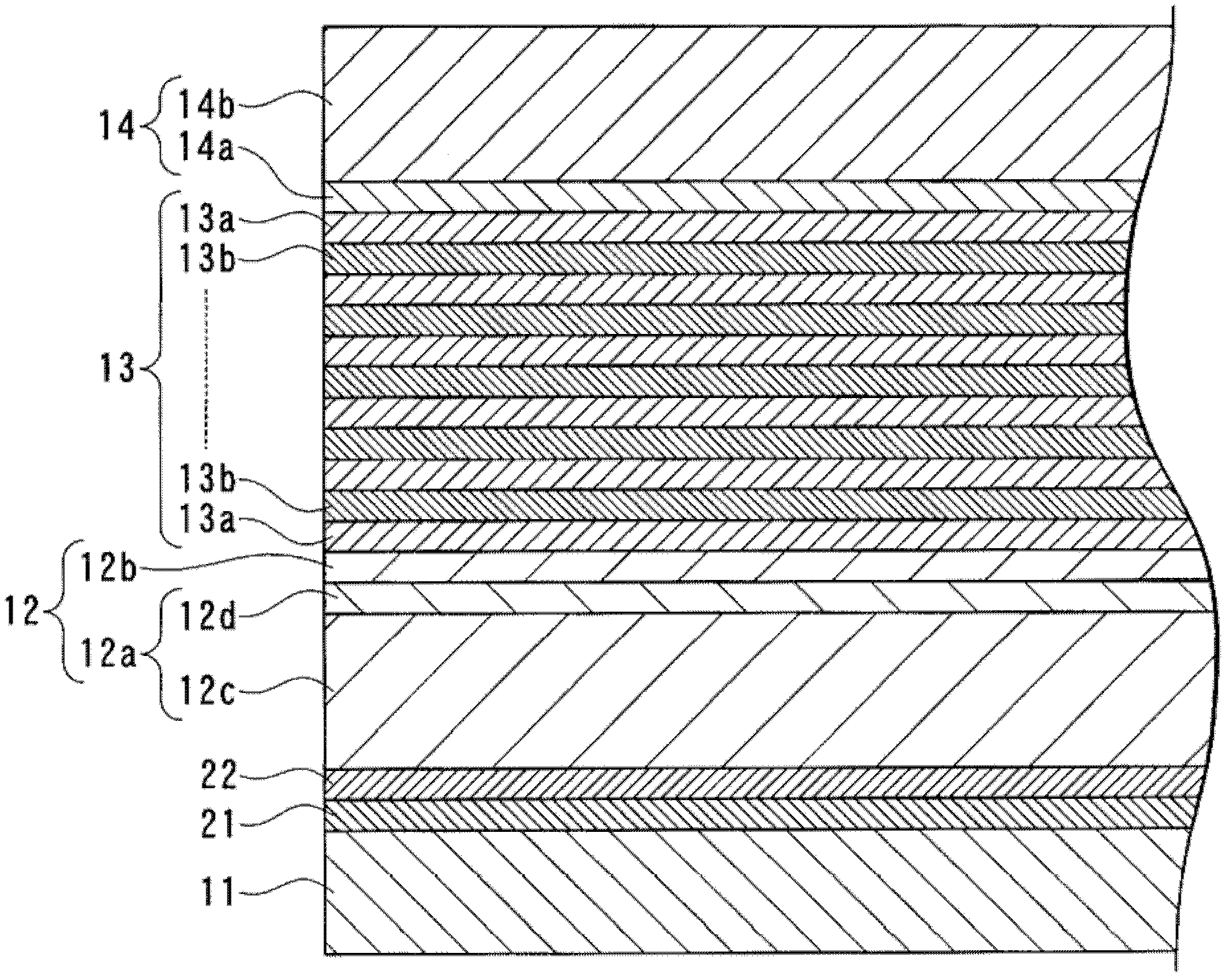

[0151] Using the method shown below, the figure 1 A semiconductor light emitting element 1 having the configuration shown.

[0152]In the manufacture of the semiconductor light-emitting element 1 of Example 1, first, on the top-view circular substrate 11 made of sapphire, the buffer layer 21 made of AlN; base layer 22; an n-contact layer with a thickness of 3.2 μm consisting of a first-step growth layer 12c made of Si-doped n-type GaN with a thickness of 3 μm and a re-growth layer 12d made of Si-doped n-type GaN with a thickness of 0.2 μm 12a; an n-cladding layer 12b of a superlattice structure with a thickness of 80 nm formed by repeatedly growing 20 layers (logarithmic) of the thin film layer composed of the n-side first layer and the n-side second layer, the n-side first layer It is composed of GaInN and has a thickness of 2nm, and the second n-side layer is composed of GaN and has a thickness of 2nm; the Si-doped GaN barrier layer with a thickness of 5nm and the In with a...

Embodiment 2

[0169] The n-cladding layer 12b is made of Ga 0.99 In 0.01 A semiconductor light-emitting element 1 was obtained in the same manner as in Example 1 except for the layer having a single-layer structure of N.

Embodiment 3

[0171] A semiconductor light-emitting element 1 was obtained in the same manner as in Example 1 except that the number of stacked thin film layers of the n-cladding layer 12b was 30 layers (30 pairs of layers (60 layers)).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com