Nitride semiconductor device

A nitride semiconductor and component technology, used in semiconductor devices, semiconductor lasers, electrical components, etc., can solve the problems of crystallinity deviation, large deviation, deterioration, etc., and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

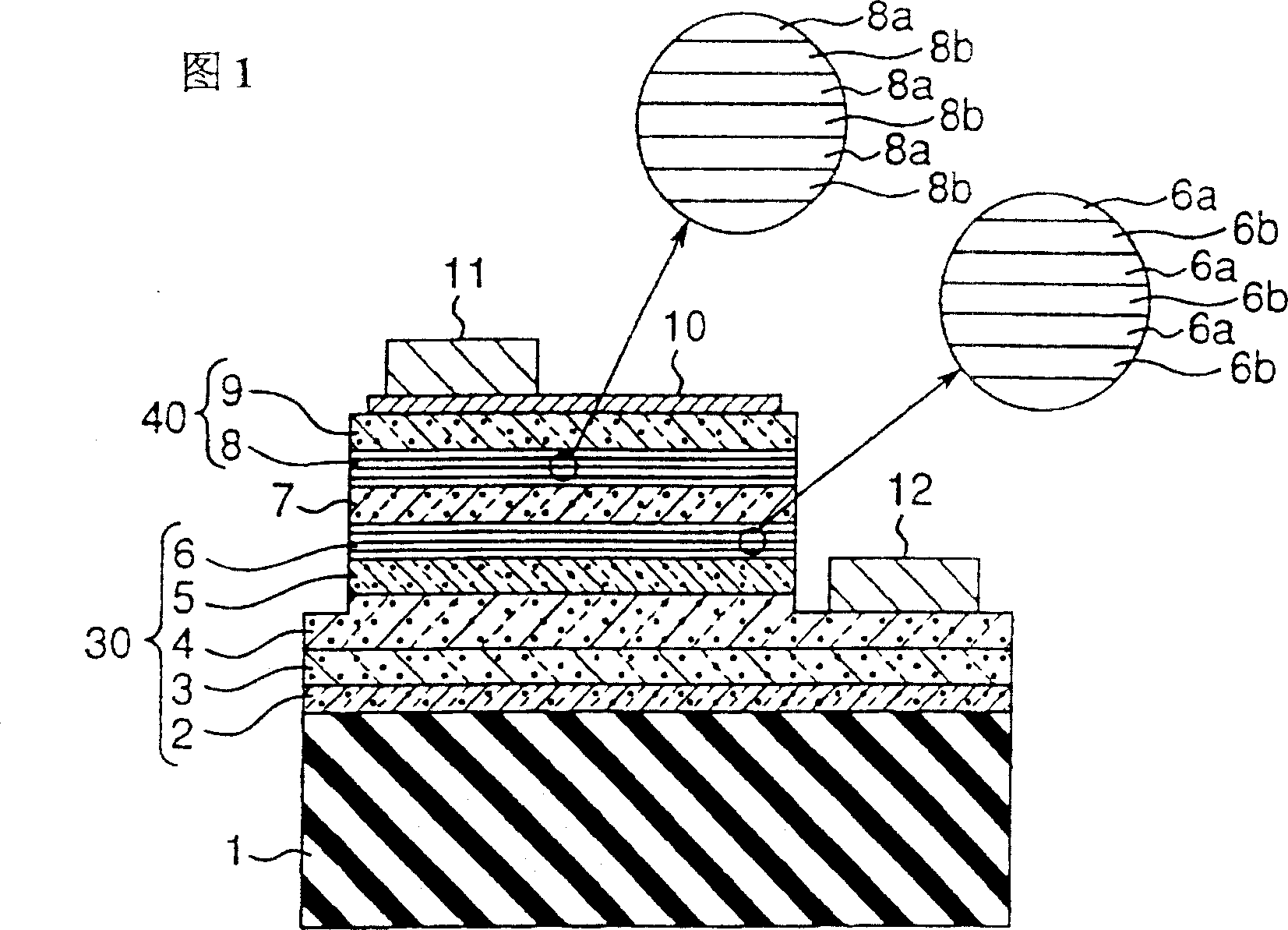

[0152] 1 is a schematic cross-sectional view showing the structure of a nitride semiconductor device (LED device) according to Embodiment 1 of the present invention. This LED element has a structure in which the following layers are sequentially stacked on a sapphire substrate 1: a first buffer layer 2 made of GaN; a second buffer layer 3 made of undoped GaN; The n-side contact layer 4 composed of; the third buffer layer 5 composed of non-doped GaN layer; the n-side multilayer film layer 6 composed of InGaN / GaN superlattice structure; the multiple quantum well composed of InGaN / GaN The active layer 7 of the structure; the p-side multilayer film layer 8 composed of AlGaN / GaN superlattice structure; the p-side contact layer 9 composed of Mg-doped GaN.

[0153] That is, the LED element of Embodiment 1 is formed on the sapphire substrate 1 by interposing the active layer 7 of the multi-quantum well structure between the n-side region 30 and the p-side region, the n-side region 30 ...

Embodiment approach 2

[0177] Next, referring to FIG. 4, a nitride semiconductor device according to Embodiment 2 of the present invention will be described.

[0178] The nitride semiconductor element of Embodiment 2 of the present invention is a light-emitting element having a double heterostructure on a substrate 1 having n-side regions 130 and The active layer 7 of the multi-quantum well structure sandwiched by the p-side region 140 .

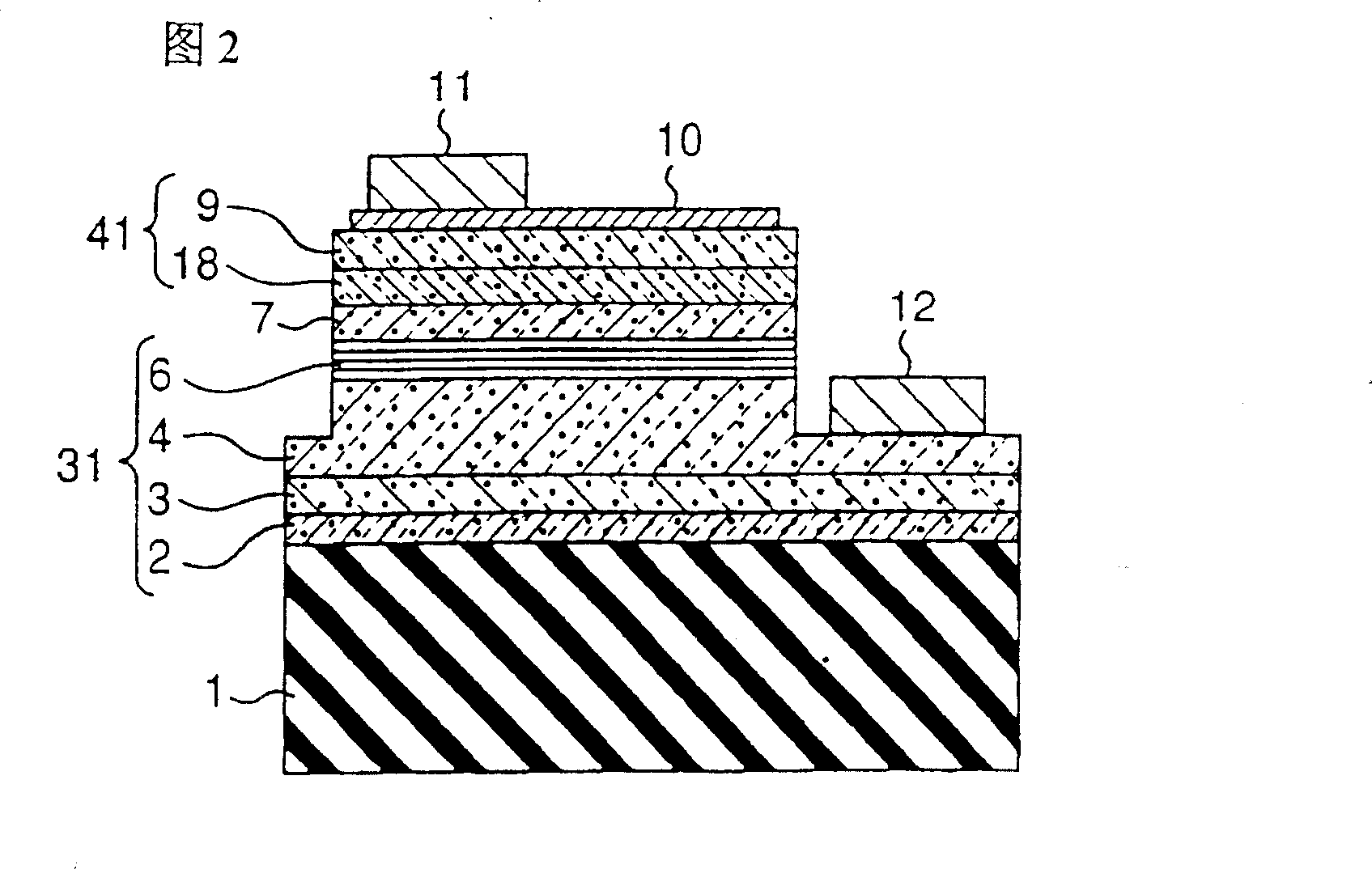

[0179] In detail, in the nitride semiconductor device of Embodiment 2, as shown in FIG. 4, the n-side region 30 is composed of the following layers: a buffer layer 102, an undoped GaN layer 103, and an n-side region containing n-type impurities. The contact layer 4, the n-side first multilayer film layer 105 containing n-type impurities, and the n-side second multilayer film layer 6 composed of the first nitride semiconductor film 106a and the second nitride semiconductor film 106b; the p-side The region 30 is composed of the p-side cladding layer 108 formed of a...

Embodiment approach 3

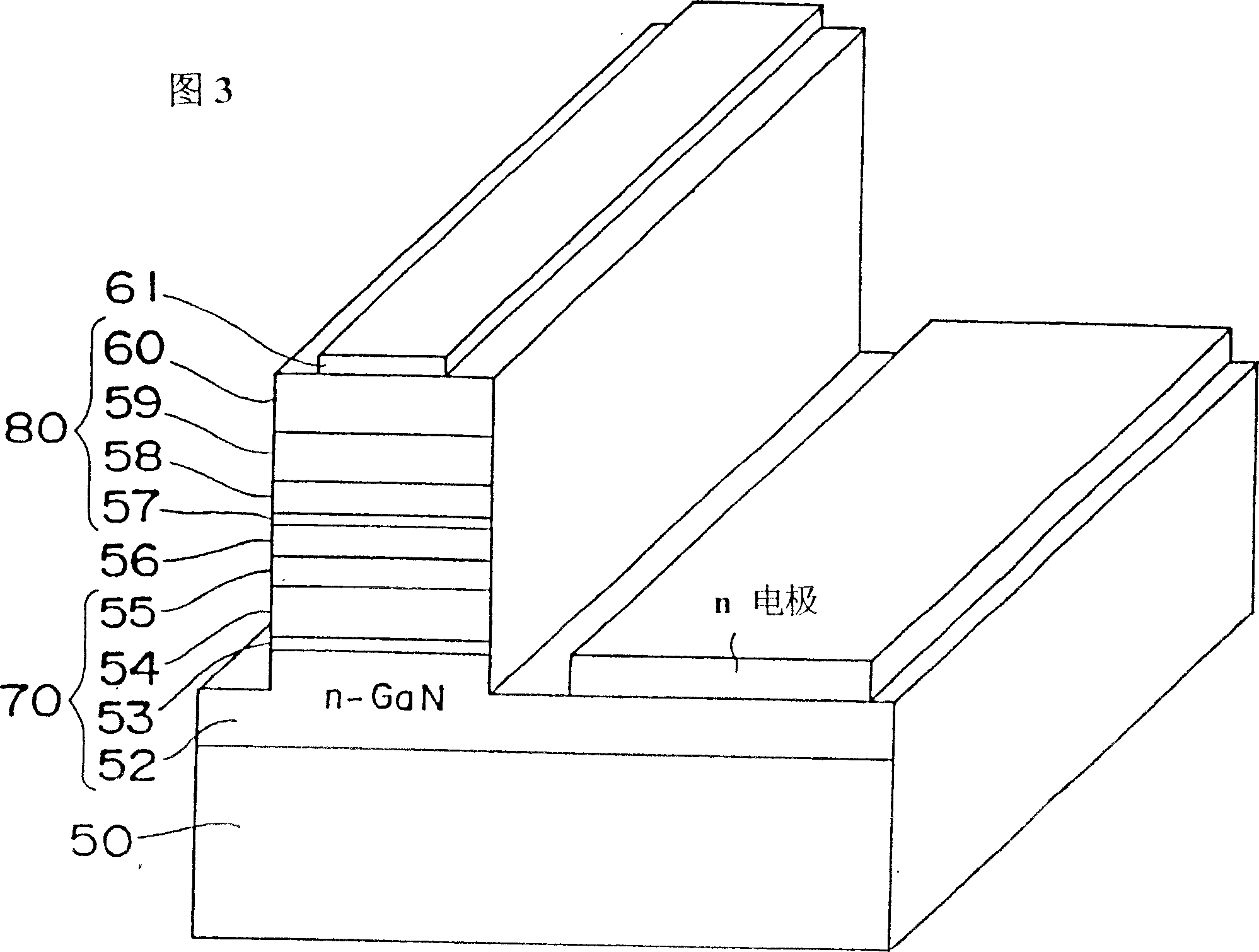

[0241] Next, Embodiment 3 of the present invention will be described with reference to FIG. 5 .

[0242] As shown in FIG. 5 , the nitride semiconductor light-emitting device according to Embodiment 3 of the present invention is structured as follows: On a substrate 1 made of, for example, sapphire, a first n-side nitride semiconductor layer 203 is sequentially formed via a buffer layer 202 , The second n-side nitride semiconductor layer 204 , the third n-side nitride semiconductor layer 205 , the active layer 7 , the p-side cladding layer 108 and the p-side contact layer 208 . Further, in the third embodiment, the light-transmitting p-electrode 10 is formed on substantially the entire upper surface of the p-side contact layer 208, and the p-pad electrode 11 for bonding is formed on a part of the p-electrode. In addition, the surface of the second n-side nitride semiconductor layer 204 is exposed on one side of the light-emitting element, and the n-electrode 12 is formed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com