Realization method for lead bonding thick aluminum wire

An implementation method and wire bonding technology, applied in the manufacturing of electrical components, electric solid state devices, semiconductor/solid state devices, etc., can solve the problems of product reliability discount, increase cost, complicated conditions, etc., and achieve simplified welding equipment and production process. Simplified, thermally large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

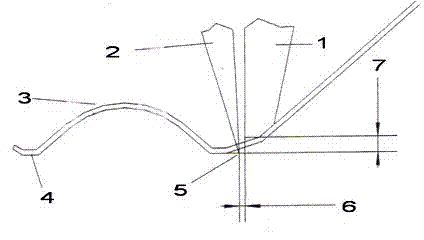

[0048] according to figure 1 When welding, adopt the present invention to carry out the realization method of thick aluminum wire wire bonding, its operating conditions are as follows:

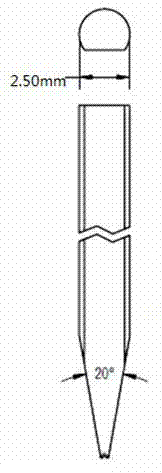

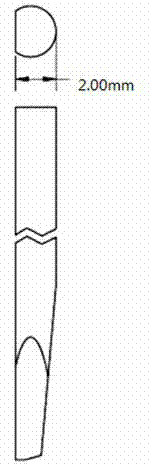

[0049] (1) Selection of chopping knife

[0050] Due to the good ductility of the aluminum wire, during the operation of the production line, it is easy to cause desoldering when pulling the wire, and it cannot be operated continuously. The chopper must be designed to match the diameter of the thick aluminum wire. , so as to ensure the smooth operation of the production line. There are several parts of the riving knife that need to be modified, including T size, BL size, ER&BF size, H size, W size, and VGW size; in addition, the selection of the material of the riving knife and the choice of surface finish ensure that the riving knife has sufficient strength to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com