Luminous diode array

A technology of light-emitting diodes and arrays, applied in the field of light-emitting diode arrays, can solve problems such as low power consumption and achieve the effects of improving internal luminous efficiency, increasing luminous output power, and increasing luminous output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

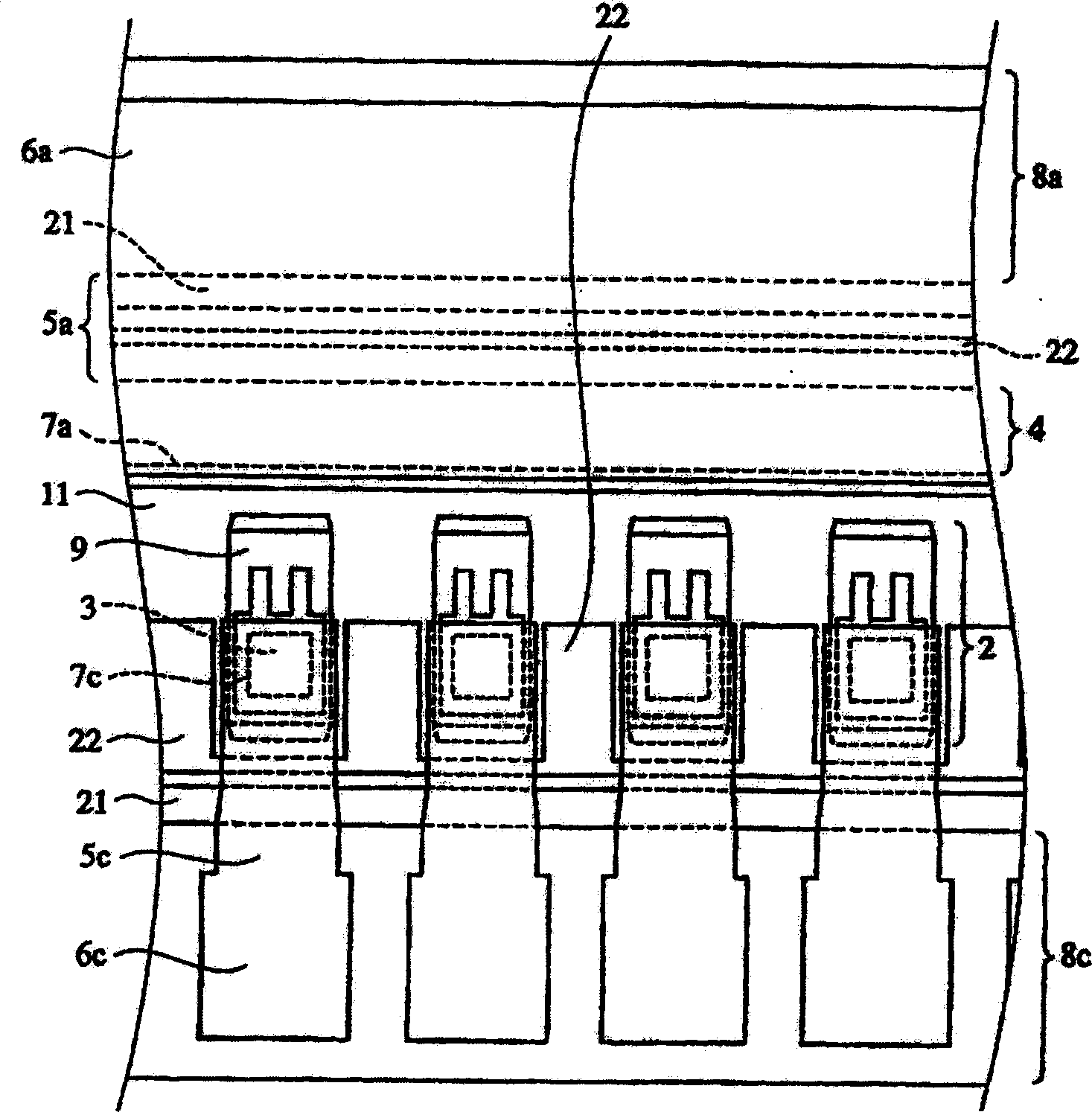

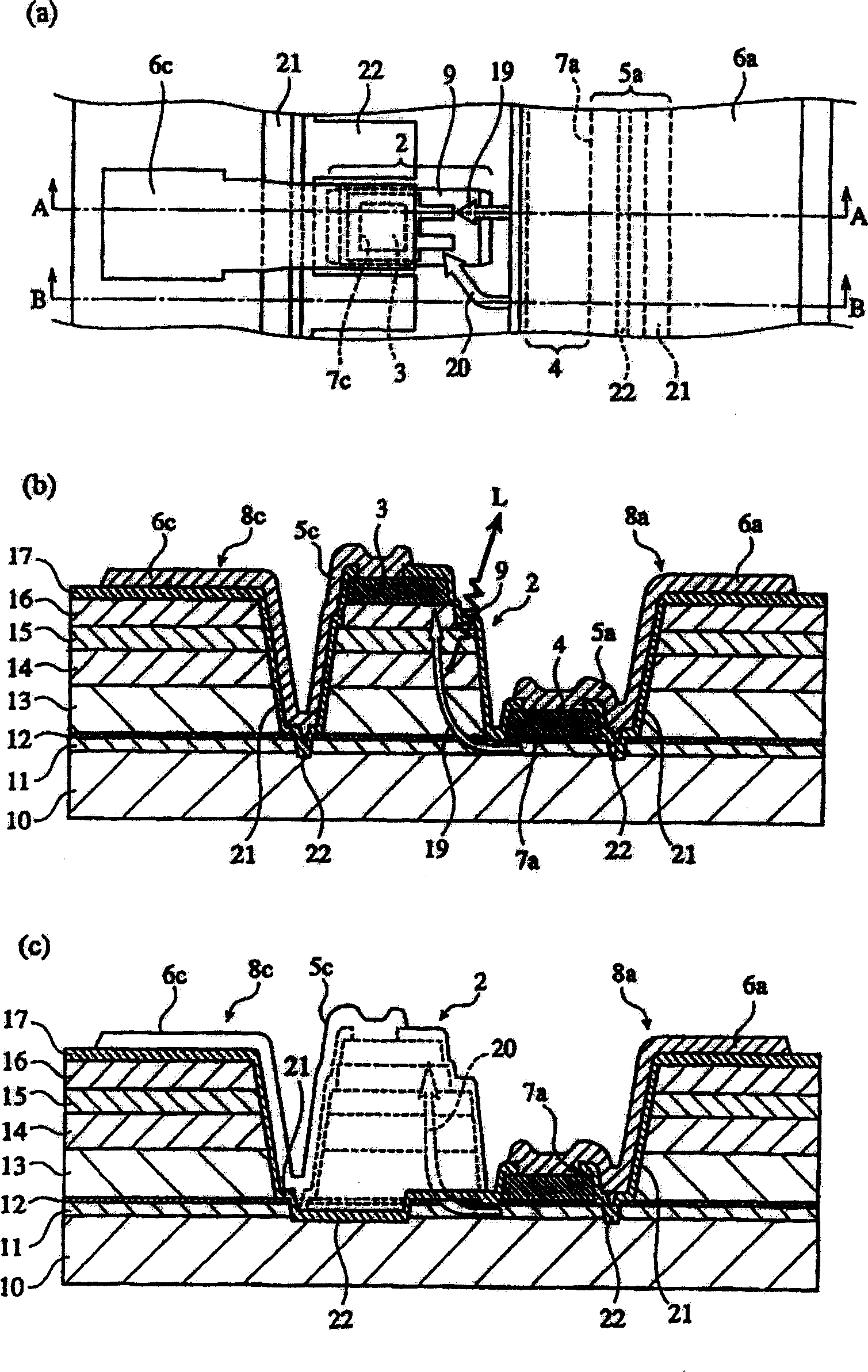

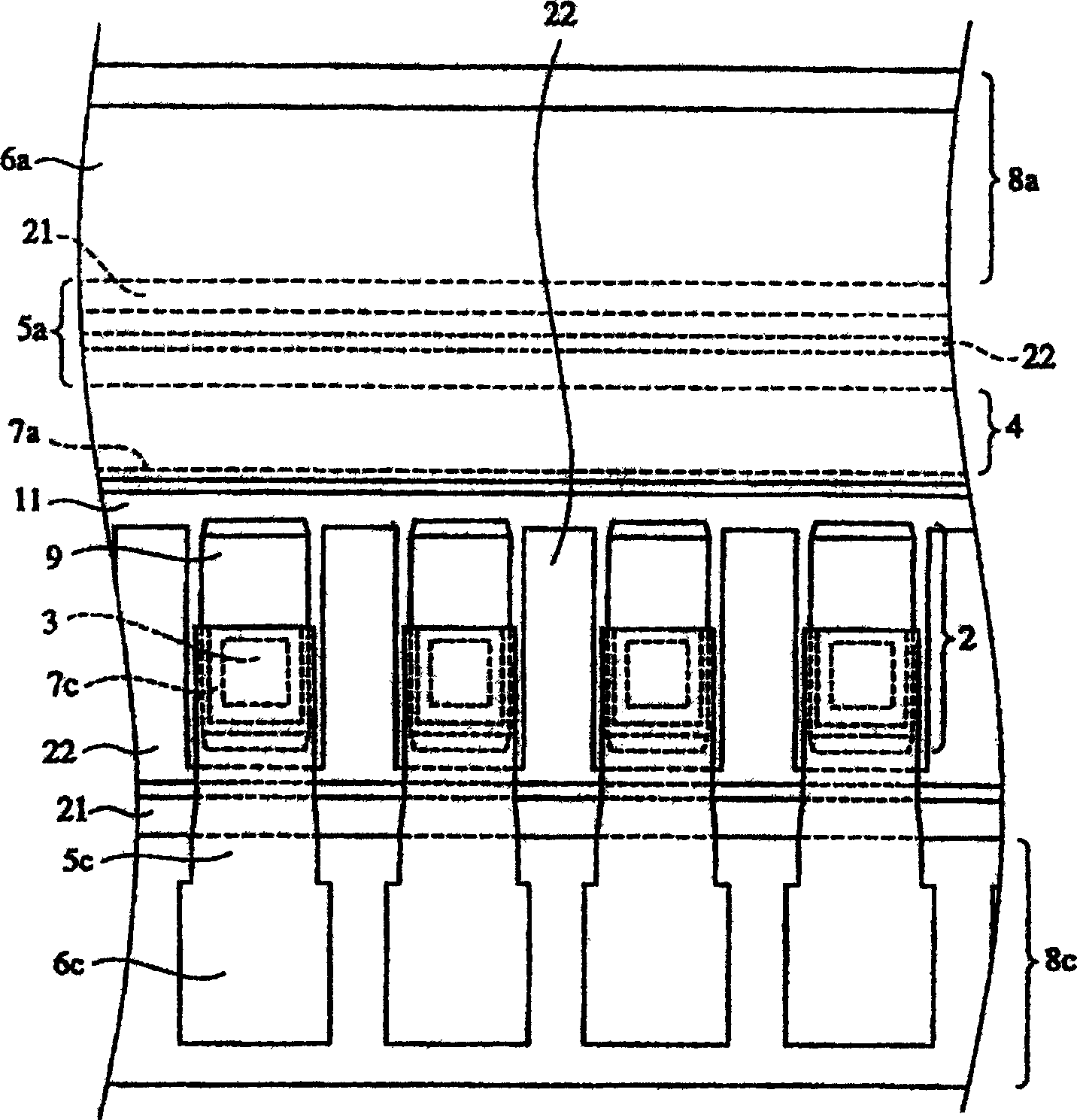

[0023] [1] Structure of LED array

[0024] Such as figure 1 as well as figure 2 As shown, the light-emitting diode array of the present invention has: a substrate 10, a plurality of light-emitting parts 2 formed on the substrate 10, a first electrode 3 formed on the upper surface of each light-emitting part 2, and a conductive layer 11. The second electrode 4 formed at a position close to the light emitting part 2 . In the illustrated embodiment, each light emitting part 2 is provided with a mesa etching groove on the epitaxial growth layer uniformly grown on the substrate 10, so that they become independent epitaxial growth layer parts.

[0025] (1) Substrate

[0026] The substrate 10 is not particularly limited as long as it is a material that can be used for a light-emitting diode, and any material can be electrically insulated from the light-emitting part. An n-type substrate or a p-type substrate can be used, and a semi-insulating substrate such as a semi-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com