Drying tube positioning and exhausting device

A technology of an air extraction device and a drying cylinder, which is used in drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of wear and matching accuracy of sliding mating surfaces, decrease, and affect positioning accuracy, and achieve cleanliness. Guaranteed axial accuracy, reducing possible effects of build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

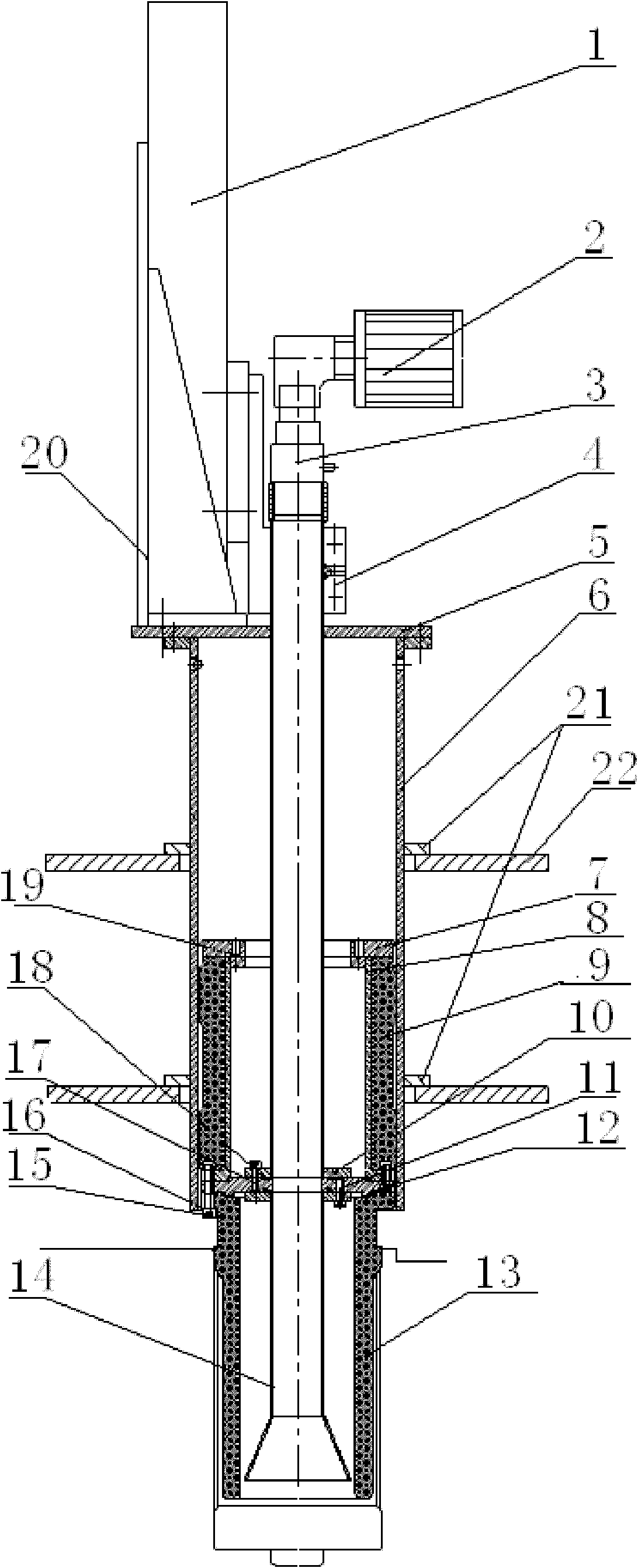

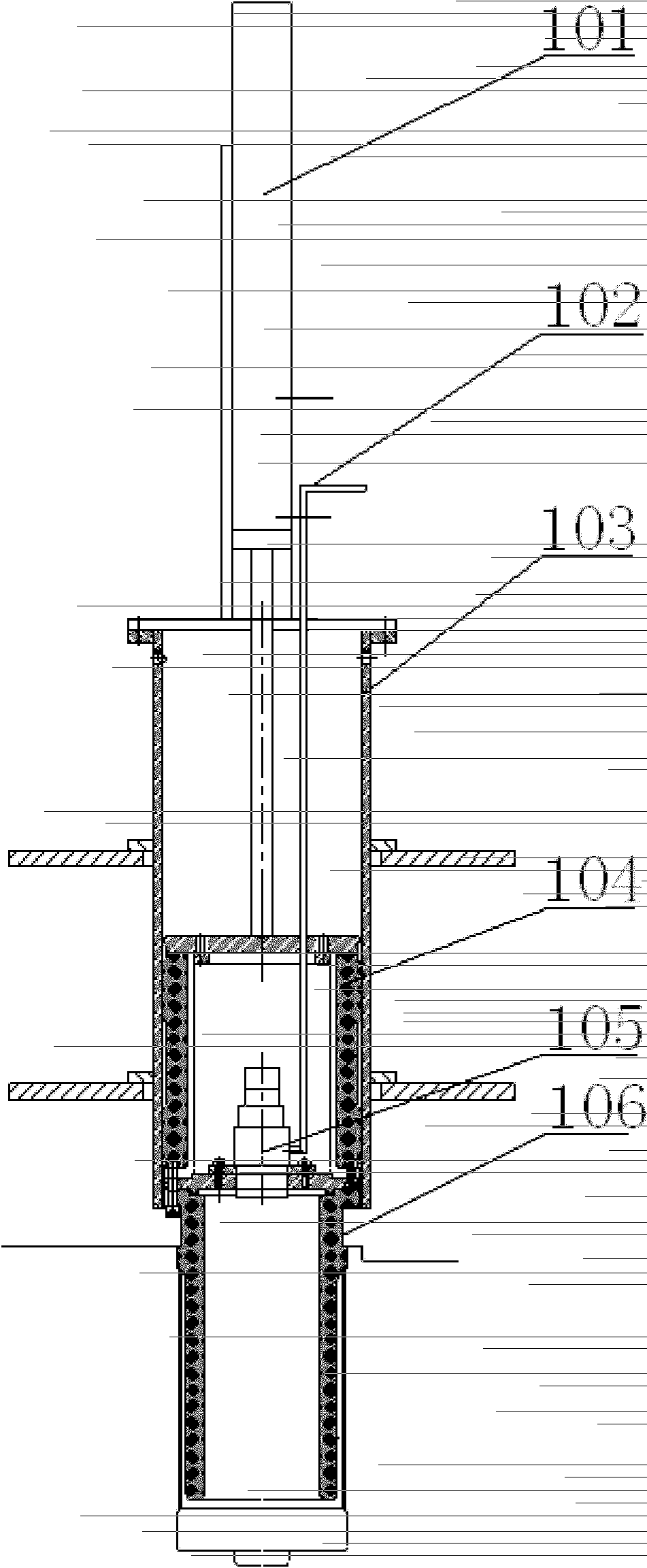

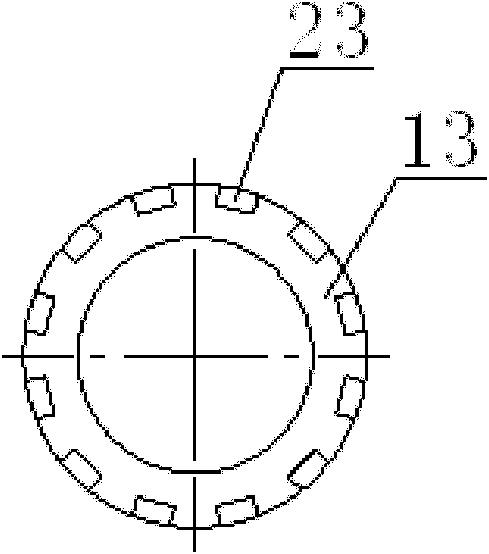

[0017] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0018] like figure 1 As shown, a drying cylinder positioning air extraction device includes a cylindrical cylinder body 6, the outside of the cylinder body 6 is fixedly connected with lugs 21, and the lugs 21 can be connected with the vehicle frame 22 to fix the cylinder body 6, the cylinder body The upper part of 6 is fixedly connected with the cover plate 5 by bolts, and a bracket 20 is installed on one side of the upper part of the cover plate 5, and the rodless cylinder 1 is fixedly connected with the bracket 20 by bolts, and the center of the cover plate 5 has a through hole, and the exhaust pipe 14 passes through the central hole of the cover plate 5, the bottom of the air extraction pipe 14 is bell-shaped, the upper part of the air extraction pipe 14 is also connected with a pneumatic vacuum generator 3, the outlet of the pneumatic vacuum generator 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com