Three-dimensional reconstruction method for internal defect of alloy firmware

A technology of 3D reconstruction and internal defects, which is applied in the direction of optical testing flaws/defects, etc., and can solve problems such as inability to simulate 3D expansion processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The three-dimensional reconstruction method for the internal defects of the alloy firmware proposed by the invention is based on the infrared non-destructive testing technology, and takes heat transfer theory into consideration. Through non-destructive testing technology, the internal defects of the alloy firmware are non-destructively tested to determine the location range of the defects. At the same time, the depth information of the defects can be determined by combining the heat transfer theory, so as to realize the three-dimensional reconstruction of the internal defects and realize the intuitive use of the current working conditions of the firmware. 3D simulation. The alloy firmware in this embodiment is an aeroengine blade as an example.

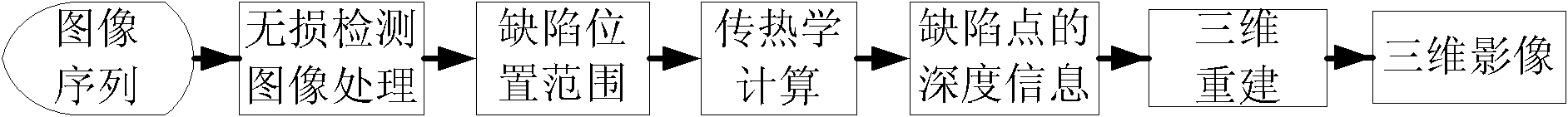

[0044] The inventive method such as figure 1 shown, including the following steps:

[0045] 1) Generate infrared images using non-destructive testing equipment

[0046] In this embodiment, the test piece is actively heated b...

Embodiment 2

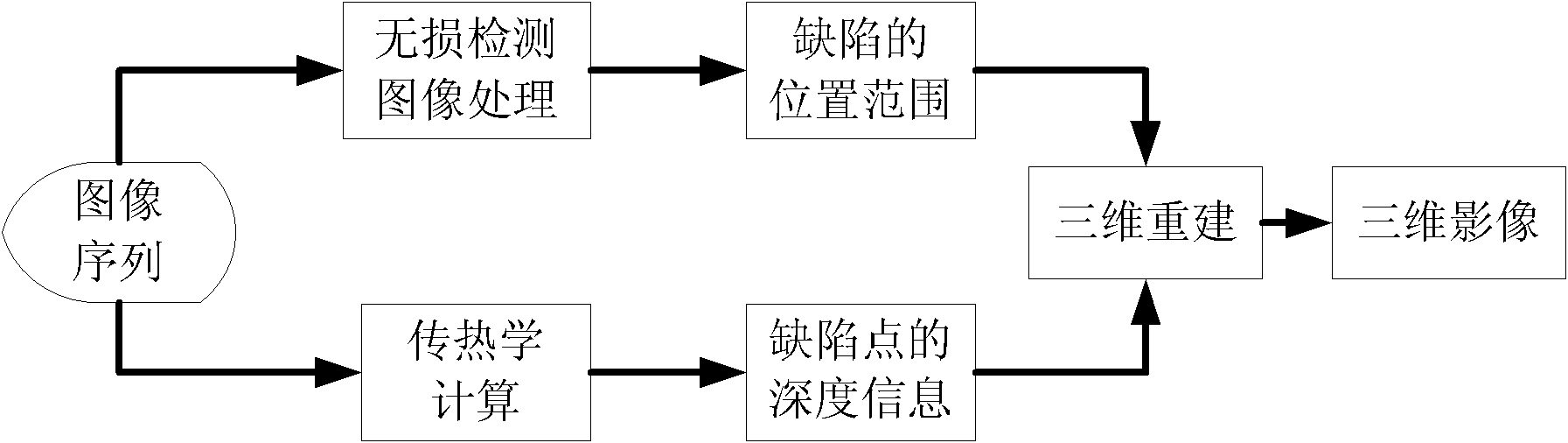

[0061] The difference of the present embodiment 1 is that: this step 2) and step 3) in the embodiment 1 are executed in parallel, such as figure 2 As shown, the details are as follows:

[0062] Generate infrared images using non-destructive testing equipment;

[0063] In the infrared image, the defects inside the alloy firmware are non-destructively detected by non-destructive testing technology, and the position range and color difference information of the defects are determined;

[0064] In the infrared image, use the theory of heat transfer to perform one-dimensional heat transfer calculation on the image to determine the depth information of any defect point;

[0065] According to the location range and depth information of the defect, the 3D reconstruction is completed through visualization technology to realize the 3D simulation of the defect.

[0066] Determining the position range of defects and color difference information and determining the depth information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com