Method for forming shallow-trench isolating structure

A technology of isolation structure and shallow trench, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of poor step height consistency and achieve the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

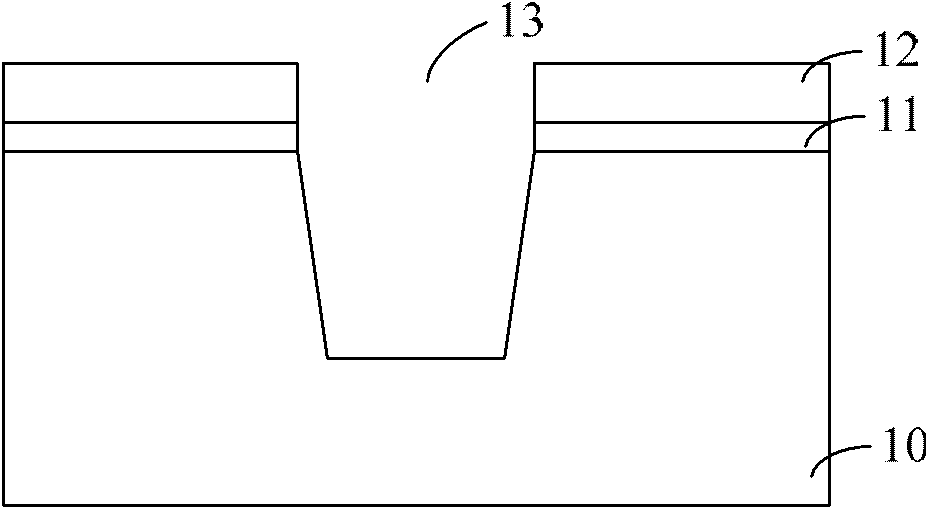

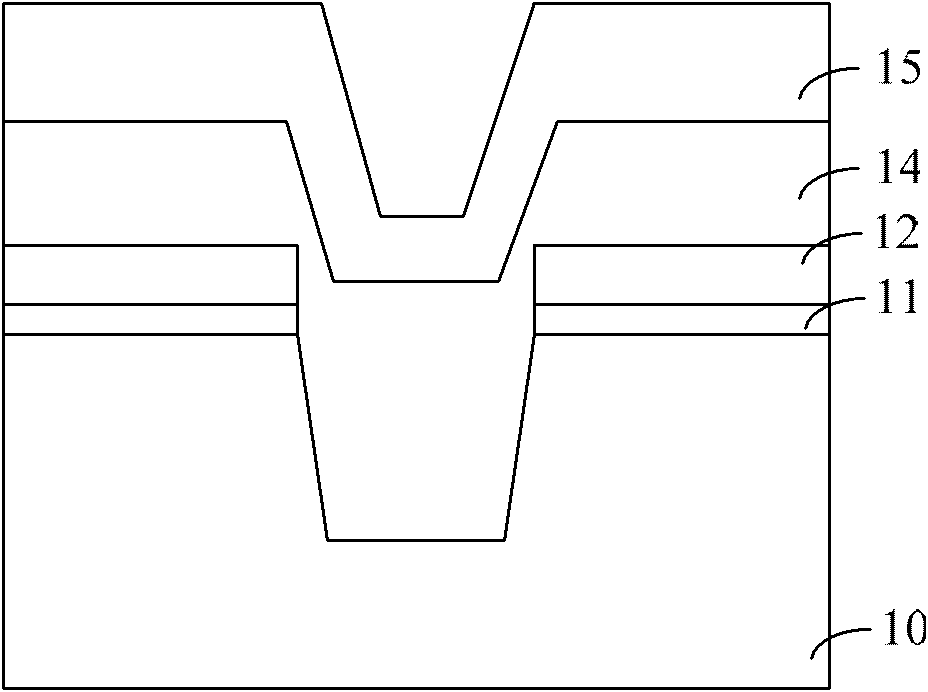

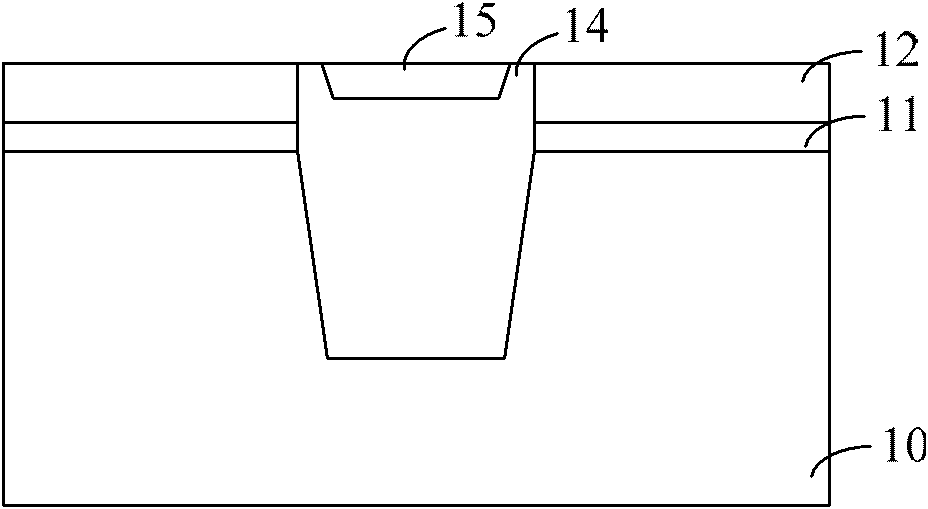

[0040] The formation process of the shallow trench isolation structure in the prior art is generally divided into two steps to fill the trench. First, a filling dielectric layer is formed to pre-fill the trench, and then a cap dielectric layer is formed on the filling dielectric layer to fill the trench. The trench is completely filled, but the formation process of the shallow trench isolation structure in the prior art will lead to the problem of poor step height uniformity.

[0041] After research, the inventor found that when forming the capping dielectric layer in the prior art, due to the high temperature of the high-density plasma chemical vapor deposition used, generally 700°C to 750°C, the previously formed filling dielectric layer The "parasitic" annealing effect increases the compactness of the filling dielectric layer after annealing, and due to the instability of the annealing effect, the filling dielectric layer between different shallow trench isolation structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com