Laser packaging method

A laser encapsulation and laser beam technology, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., to achieve the effect of excellent overall quality, good adaptability and wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

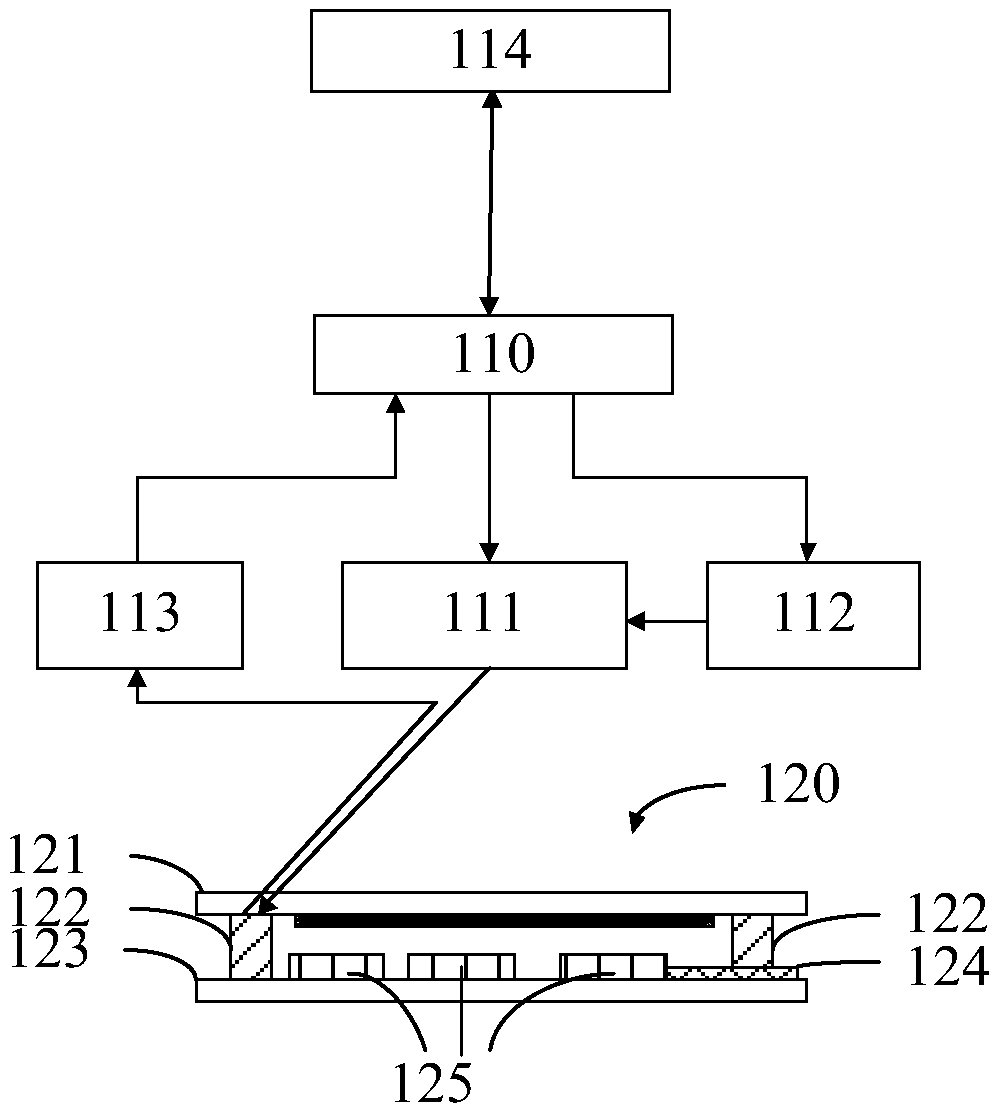

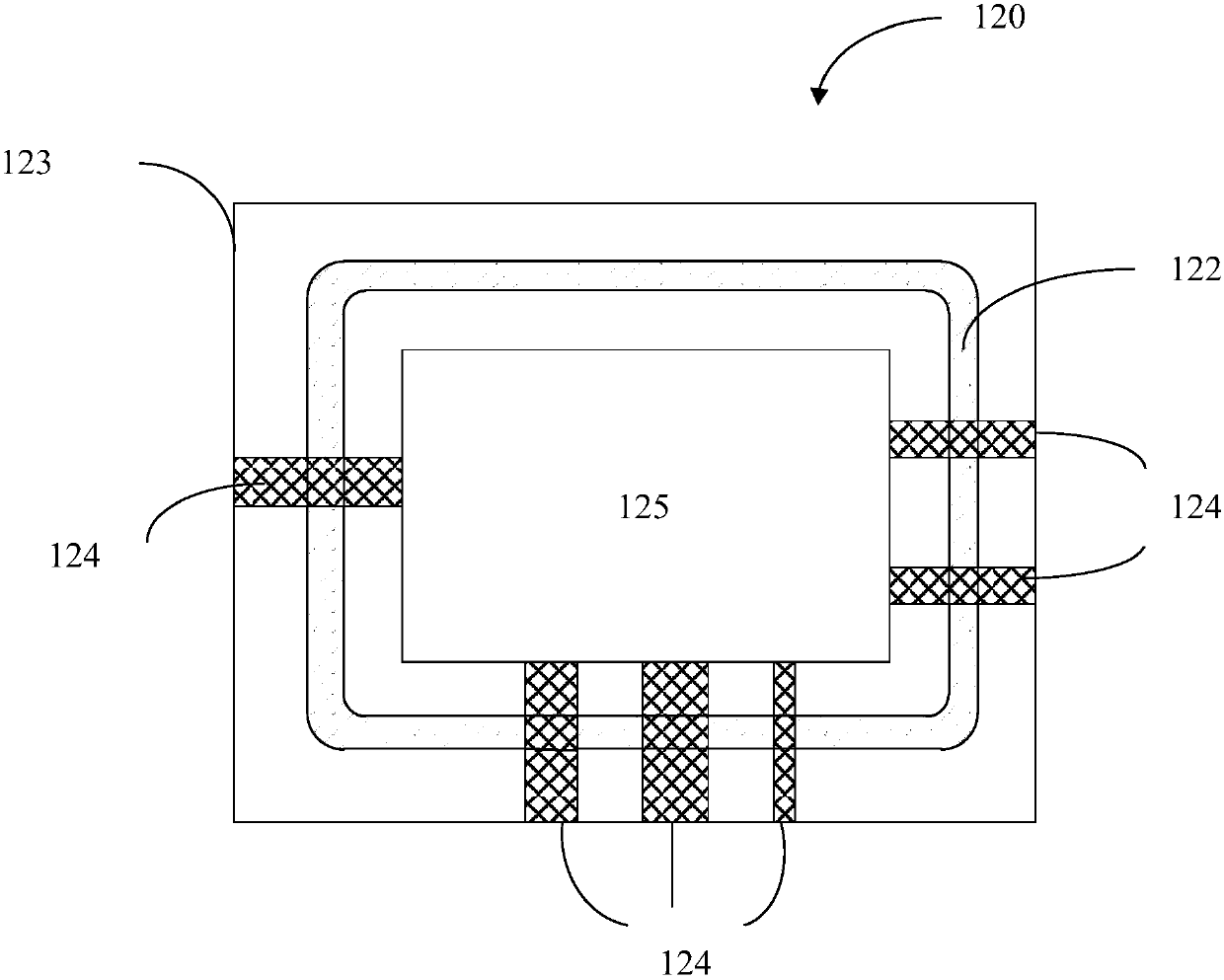

[0050] This embodiment is used to form an airtight seal with glass frit for the OLED display 120, wherein the OLED display 120 is a typical glass package, and the main structure of the OLED display 120 includes a cover glass 121, a glass frit 122, and a substrate glass. 123 , OLED layer 125 and electrode 124 . Wherein, the glass frit 122 is located on the substrate glass 123 of the OLED display 120, and its top view is shown as Figure 1b shown. The glass frit 122 is pre-cured on the substrate glass 123 through screen printing and pre-sintering steps to form a rounded rectangular sealing line with a certain thickness. The OLED layer 125 on the substrate glass 123 is located inside the sealing line of the glass frit 122 , and there are electrodes 124 on the substrate glass 123 connecting the inside and outside of the OLED display 120 .

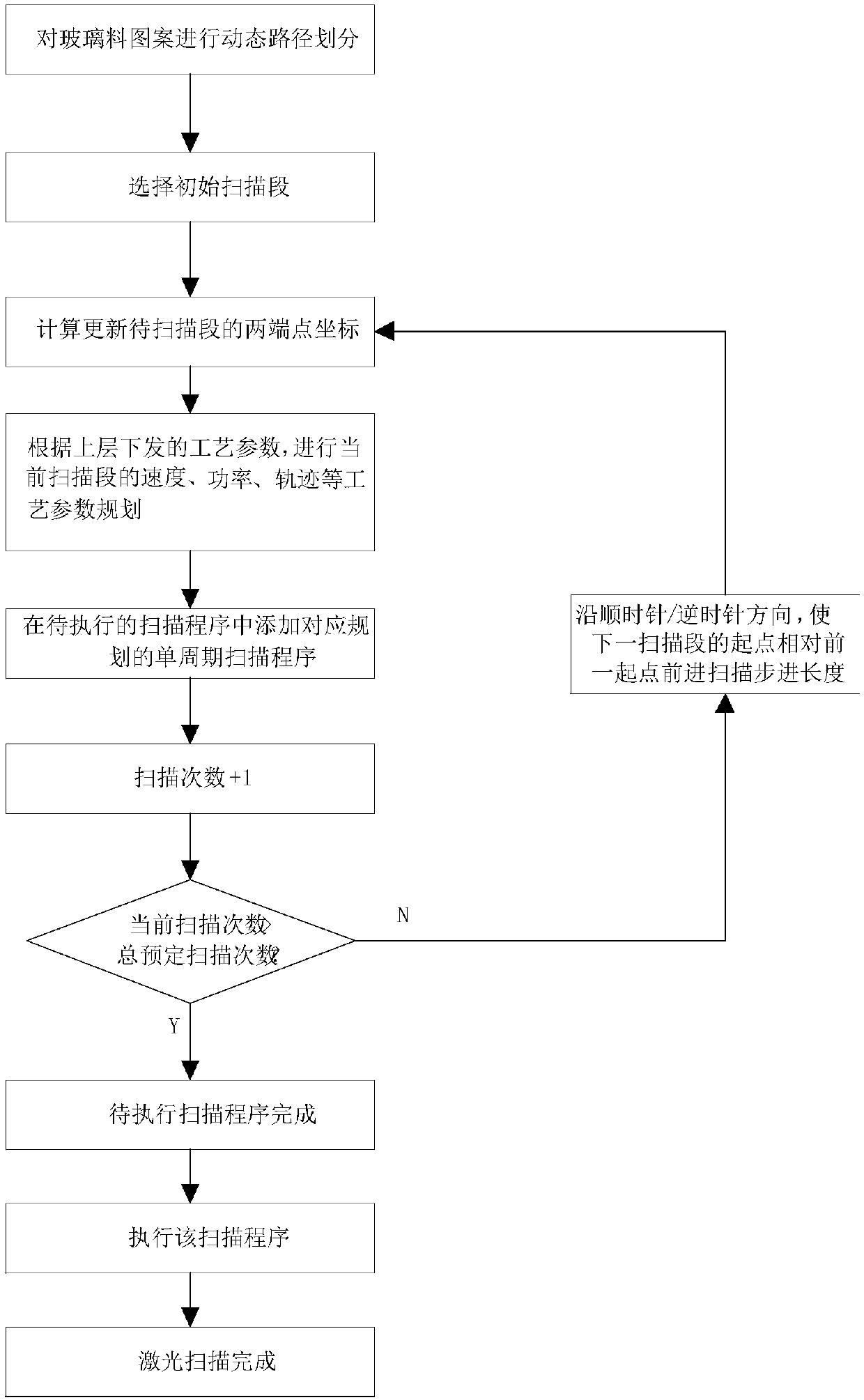

[0051] Such as figure 2 As shown, the present invention provides a laser packaging method, using a laser to heat the glass frit 122 patter...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is that the pattern of the glass frit 122 is a non-sealed pattern, including straight lines and open lines of any shape.

[0077] Therefore, if Figure 12 to Figure 15 As shown, step 1 of this embodiment includes:

[0078] The frit 132 pattern is divided into N counterclockwise or clockwise 1 scan segments, from the first scan segment to the Nth scan segment 1 -The positions between the start point 133 and the start point 133, the end point 134 and the end point 134 of two adjacent scan segments 132 in one scan segment 132 are offset by L 1 , L 1 much less than the length L of the first scanning segment 132 3 ;

[0079] If take N 1 =Ceiling(L / L 1 )-(L 3 / L 1 )+1, the Nth 1 - 1 scan segment 132 with Nth 1 Position offset L between the starting point 133 and the starting point 133 of each scanning segment 132 1 , the position offset L between the end point 134 and the end point 134 2 , where L is the tot...

Embodiment 3

[0090] Such as Figure 16-17 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, the glass frit 122 pattern can be divided into a plurality of sub-scanning areas 210, and adjacent sub-scanning areas 210 have overlapping areas 211, so The length of the overlapping region 211 is usually the length of one scanning segment. Generally, the length of the sub-scanning area 210 should be much longer than the length of the scanning segment. For a single sub-scanning area 210, its path planning and scanning steps are the same as those in Embodiment 1 or Embodiment 2, and will not be repeated here. The package scanning sequence for the plurality of sub-scanning areas 210 may be arbitrary. The single sub-scanning area 210 has the following characteristics after completing the dynamic quasi-synchronous scanning:

[0091] The areas at both ends of the sub-scanning area 210 are defined as overlapping areas 211 , and the areas betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com