Plastic flat filament winding machine

A technology of plastic flat wire and winding machine, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., which can solve the problems of uneven molding, waste of cost, high scrap rate, etc., to reduce maintenance links, reduce The effect of low cost and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

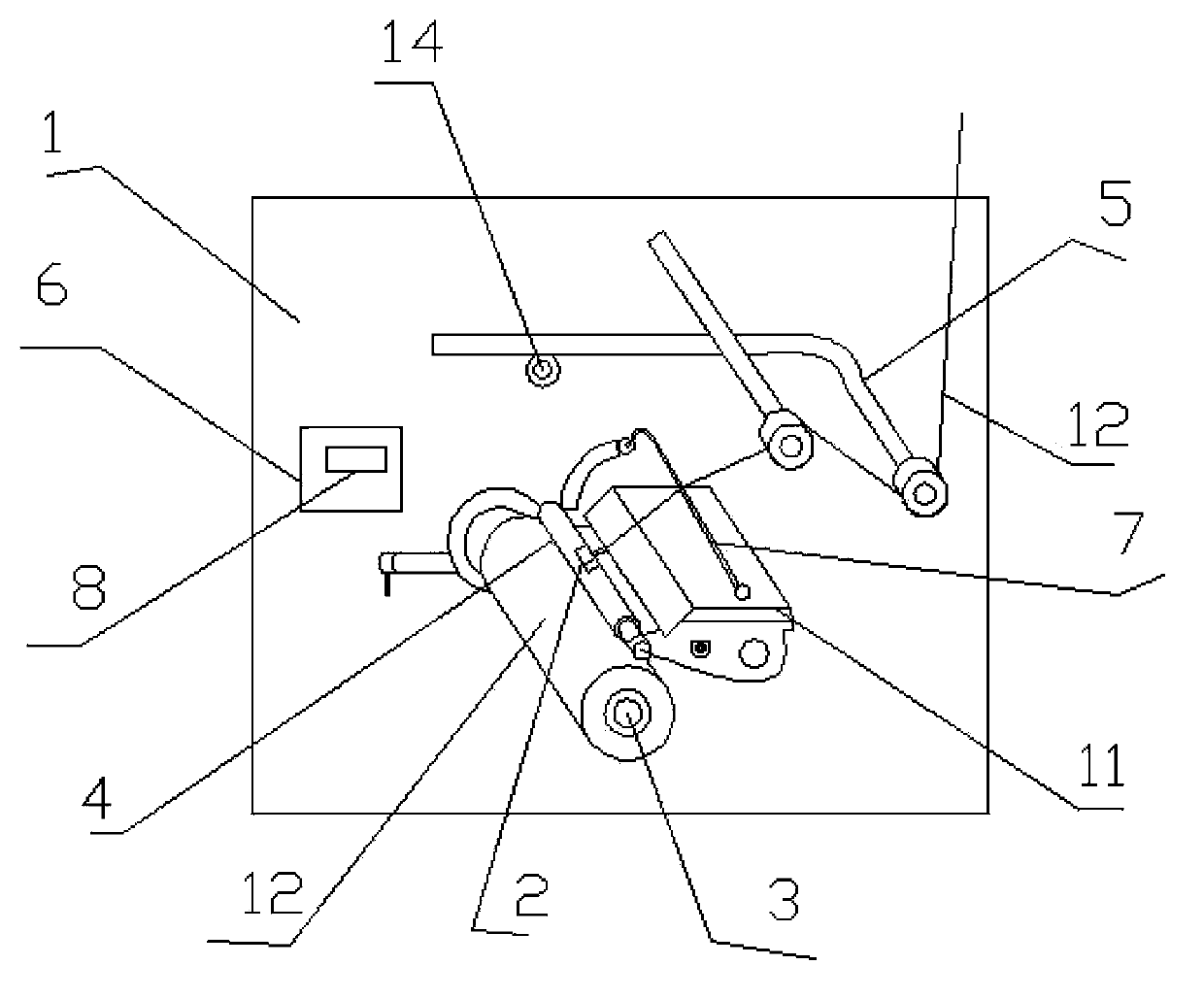

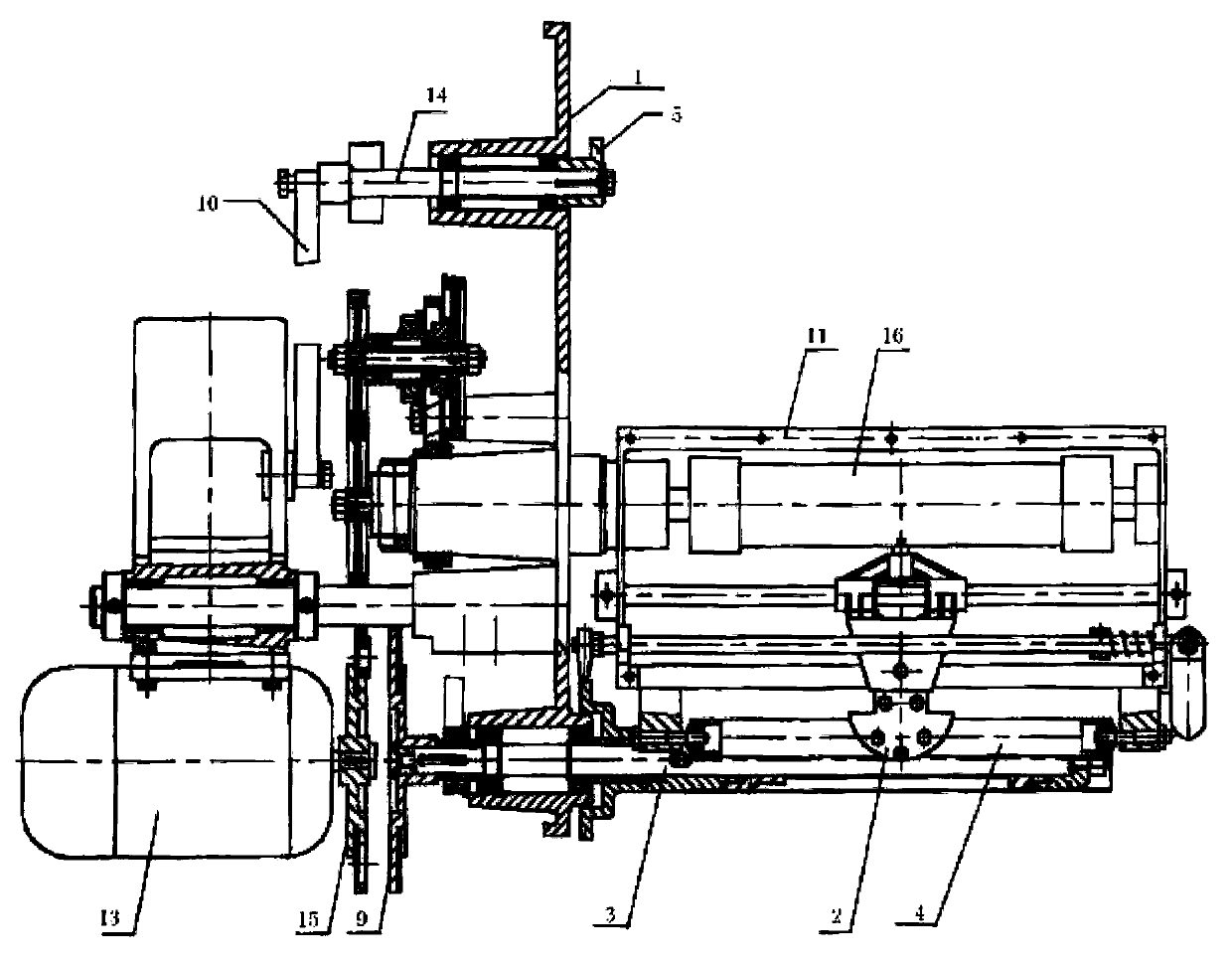

[0013] Such as figure 1 As shown, a magnetic transmission constant tension winding machine of the present invention includes a panel 1, a three-phase asynchronous motor 13, a shuttle 2, a bobbin 3, a support rod 4, a swing arm 5, and a power supply device 6; the power supply device 6 It is arranged on the panel 1 and is connected with a three-phase asynchronous motor 13 provided on one side of the panel 1; the three-phase asynchronous motor 13 drives the bobbin 3 through the cooperation of the driving disk 15 and the driven disk 9 , the bobbin 3 is arranged on the panel 1 through a bearing; the swing arm 5 is connected with a motor adjusting rod 14 arranged on the panel 1 through a bearing, and the motor adjusting rod 14 connects with the connecting rod 10 The three-phase asynchronous motor 13 is connected; the three-phase asynchronous motor 13 is connected with a reciprocating screw 16 through a gear, and the reciprocating screw 16 is connected with the shuttle 2; the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com