Intelligent tobacco formulation method

A formula and intelligent technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as low efficiency, slow speed, and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

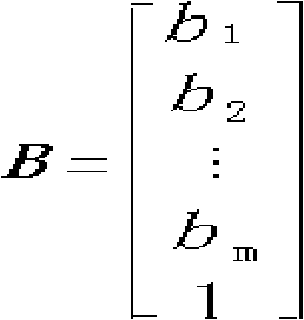

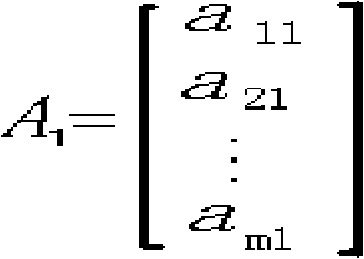

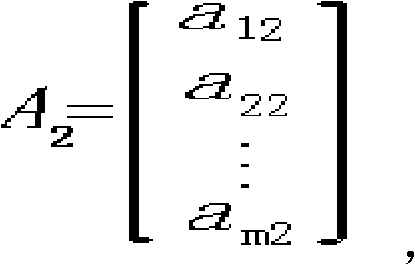

Method used

Image

Examples

Embodiment 1

[0045] In order to test the accuracy and functional applicability of the intelligent tobacco distribution system, we selected the corresponding raw tobacco leaf composition formula from the inventory according to the system-related chemical index data (see Table 2) measured by the leaf group formula LB.

[0046] Table 2 Leaf group formula LB and corresponding simulated formula ingredient index list

[0047]

[0048]

[0049] Tobacco leaf formulation was simulated with the leaf group formulation LB of the intelligent tobacco distribution system. The simulated formulation results were arranged from low to high according to the relative average deviation of the formulation, and four formulation results were provided. The results are shown in Table 3. The measured values of the corresponding four simulated formula components are shown in Table 2. It can be seen from the index values of the formulas in the table that the simulated formula and the leaf group formula are ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com