Drill feeder of automatic drilling machine,

A technology of feeding device and drilling machine, applied in drilling/drilling equipment, components of boring machine/drilling machine, metal processing equipment, etc. The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

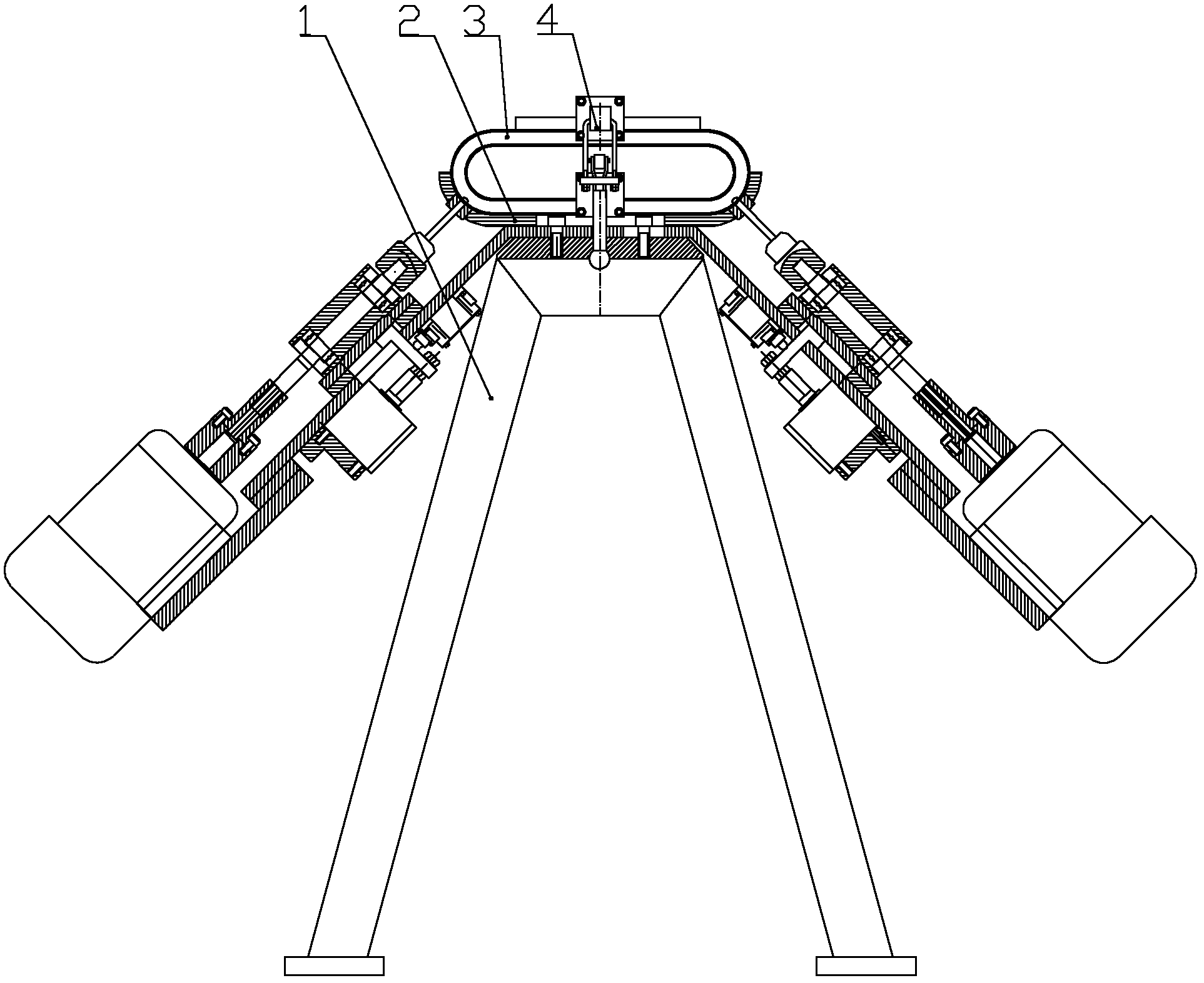

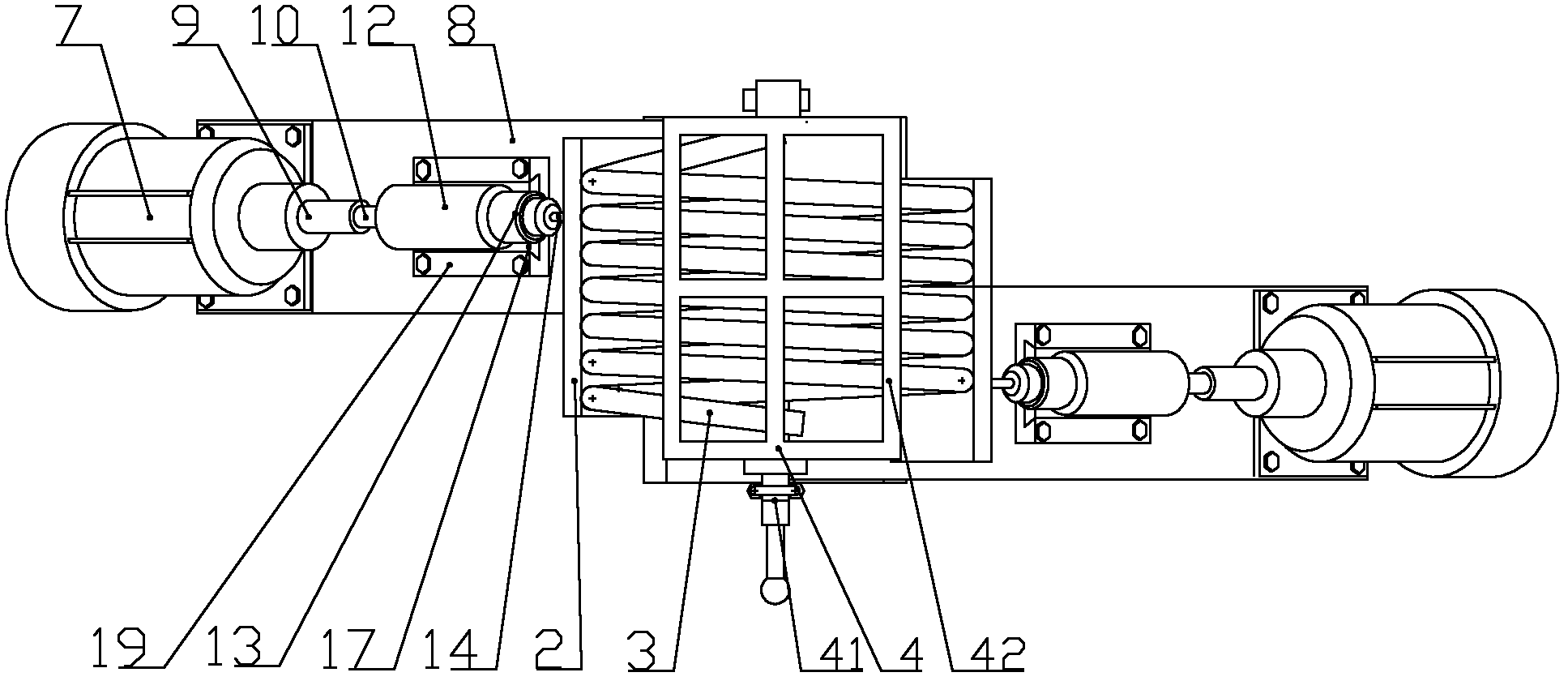

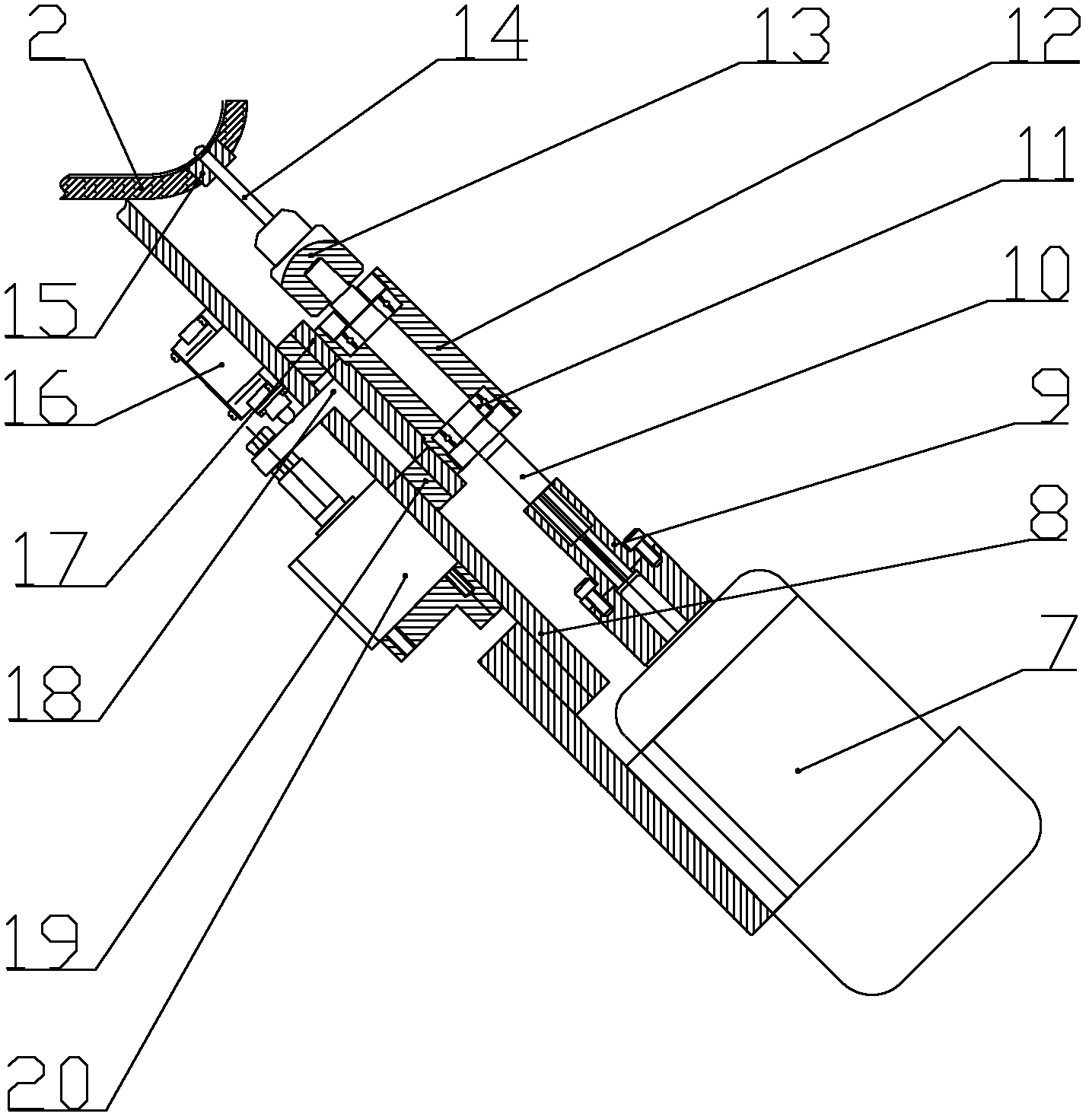

[0012] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

[0013] according to figure 1 , figure 2 and image 3 As shown, the drill bit feeding device of the automatic drilling machine described in this embodiment includes a spline sleeve 9 connected to the output shaft of the motor 7, a spline shaft 10 coaxially slidingly connected with the spline sleeve 9, and a spline shaft 10 The other end of the drill chuck 13 is coaxially connected with the drill bit 14; the middle part of the spline shaft 10 is sleeved with a shaft sleeve 12, and the two ends of the shaft sleeve 12 are connected with the spline shaft 10 through a bearing 11; the shaft sleeve 12 is connected with a driving part that drives it to move axially along the spline shaft 10.

[0014] The motor 7 is fixed above the rig base plate 8, and the driving part is arranged below the rig base plate 8; the bushing 12 is connected wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap