Pressure-regulating vacuum round and square dual-purpose three-dimensional continuous foaming machine

A technology of vacuum foaming and foaming machine, which is applied in the field of pressure-regulating vacuum, square and circle, three-dimensional continuous foaming machines, can solve the problems of large equipment installation area, uneven pores of finished products, and large degree of environmental pollution. High product quality, small footprint, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

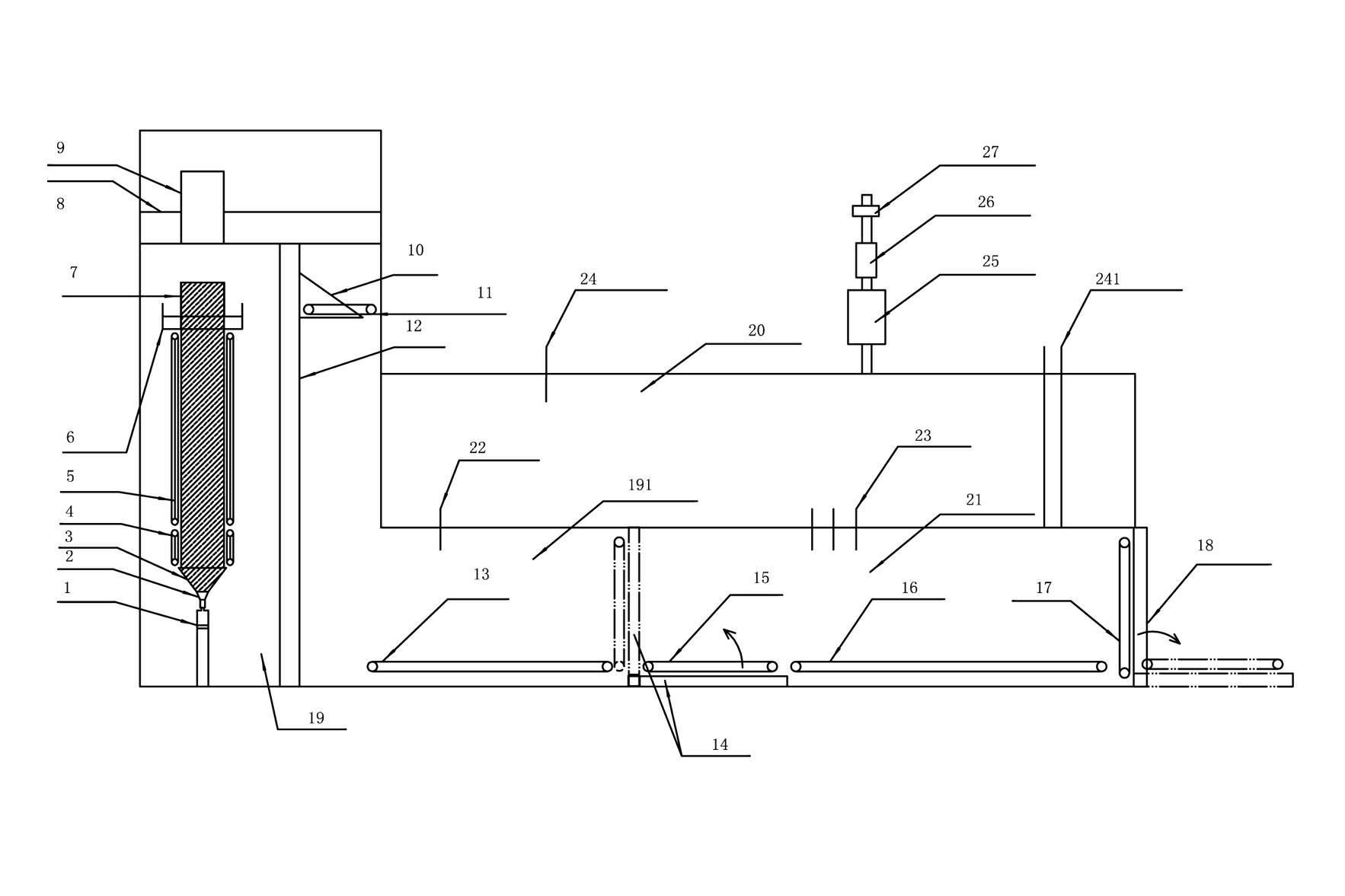

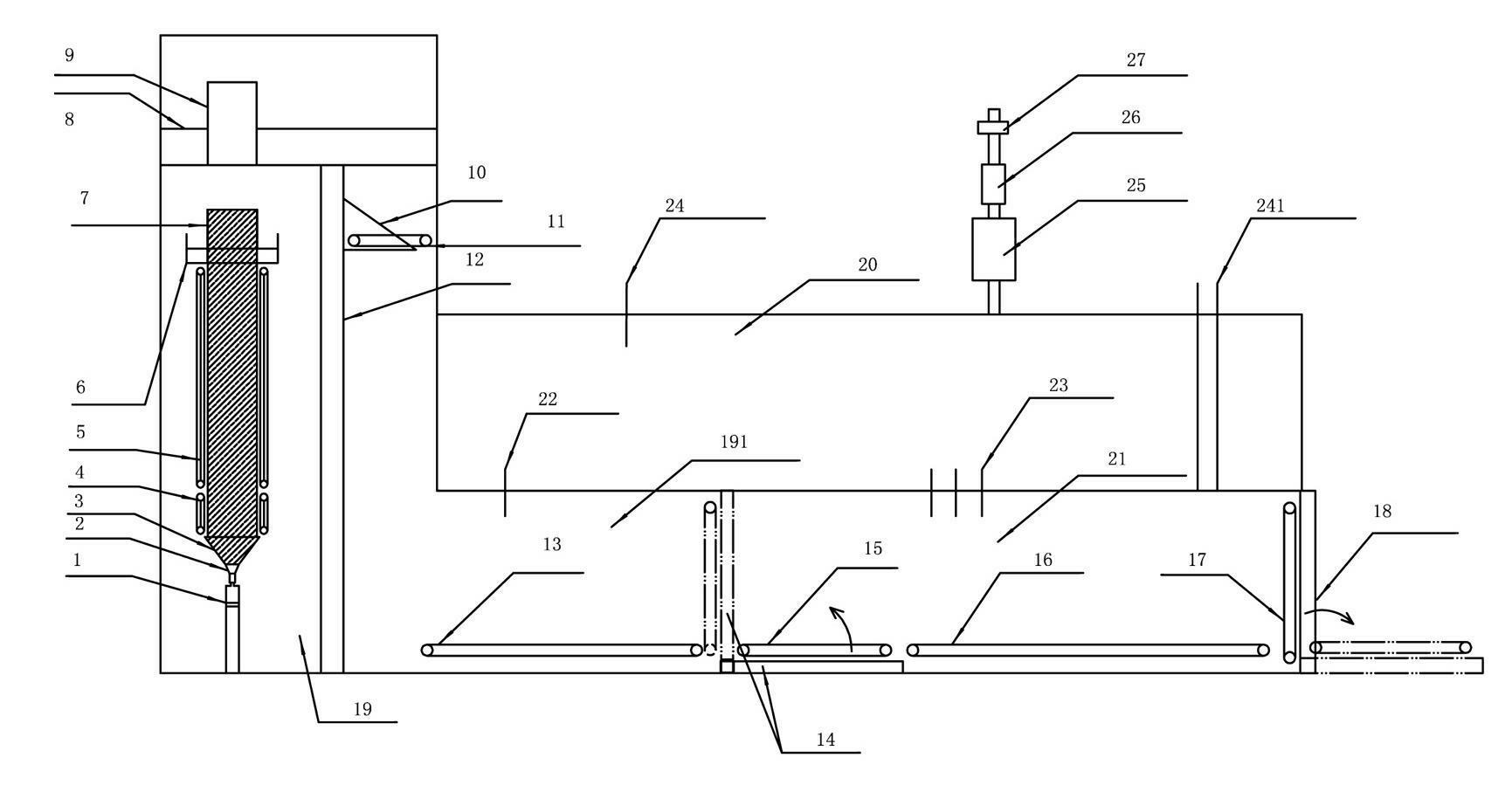

[0024] see figure 1 Shown: a pressure-regulating type vacuum and radius dual-purpose three-dimensional continuous foaming machine, which includes a vertical vacuum foaming cabin 19, a pressure-regulating delivery cabin 191, a pressure-regulating storage cabin 21, and a vacuum pumping and gas distribution system;

[0025] The vertical vacuum foaming cabin 19 communicates with the pressure-regulating delivery cabin 191, and the pressure-regulating delivery cabin 191 communicates with the pressure-regulating storage cabin 21;

[0026] An air distribution cabin 20 is arranged on the pressure regulation delivery cabin 191 and the pressure regulation storage cabin 21, and the air distribution cabin 20 communicates with the pressure regulation delivery cabin 191 through the air pressure balance conversion control valve 22, and the gas distribution cabin 20 communicates with the pressure regulation delivery cabin 191 through the gas distribution valve 23 Communicate with the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com